This question comes up a lot, why does high engine load yield more efficient BSFC numbers?

Most people on this forum know that if they run around 80% engine load while accelerating their car to the desired speed they can improve their fuel mileage.

They also know if they get closer to 100% engine load the fuel mileage will suffer. This is due to the engineers building into the ecu a

"High Load Fuel Enrichment" map using a Threshold TPS or Load factor or sometimes both. Running at normal engine load your engine runs in

"closed loop" 14.7 stoich. When High Load Fuel Enrichment kicks in, your engine then switches to "open loop" mode, and reads off the fuel table and will be richer then 14.7 stoich. How much richer depends on the engine the load amount ,rpm, etc...

They're two main reason you have a "high load fuel enrichment".

High Load Fuel Enrichment is used for "Thermal Management purposes".

Thermal Management is basically adding more fuel to the engine for cooling reasons. The extra fuel pulls heat out of combustion chamber, cylinder, and piston top etc. At high engine load and low rpm you have a combustion event that is very slow so there is more time for the heat to transfer into the engine combustion chamber, engine block, piston etc.

The other main reason for running a high engine load fuel enrichment is at low rpm and high load there is more time during the combustion stroke for the engine to detonate. Example at 1200 rpm one engine cycle takes 100 milliseconds or (100ms) to complete. At 3000 rpm it only takes (40ms) for one engine cycle to complete. Higher rpm and a richer air to fuel ratio also promotes faster flame speed!!! This helps with detonation because the flame front travels faster across the combustion area before a hot spot can ignite before the spark plug ignites the air/fuel mixture. Higher rpm also promotes a better air fuel mixture.

So after reading all this it sounds like if we stay out of the "high load fuel enrichment" and run a higher rpm to promote better combustion cooling, faster flame speed, and better air/fuel mixture then higher rpm is the way to go???

Well nope!!!

The problems as most of you know is the intake pumping losses. Intake pumping losses are greater then all the above "high rpm" advantages.

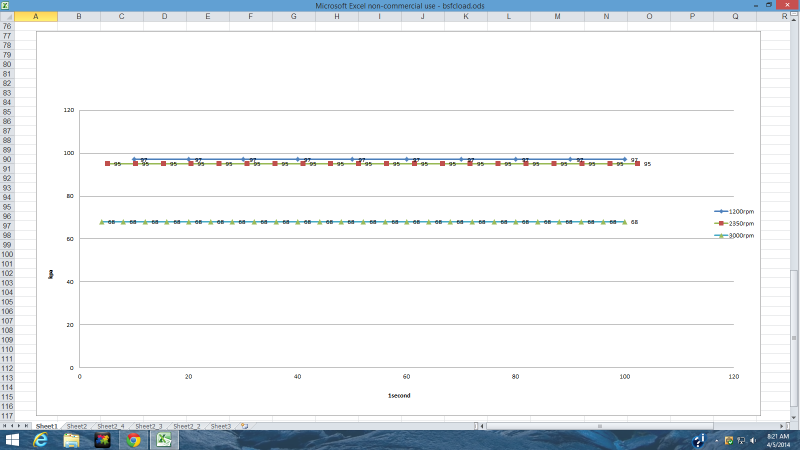

Chart time:

In the above chart is some data from my logs of my car last year.

The engine is a 2.0L 85mm bore, 88mm stroke

The lowest line in the graph is at 3000 rpm

-9.36 inch/hg or 68 kpa (L) more pumping loss

3.94 lbs/min of air (N/A)

12.81 bsac (L) less power from air

25 engine cycles/sec (L) greater pumping losses, lower kpa at the intake valves

21 a/f ratio (L) raises pumping losses

15.7 whp (L) more power needed for higher mph

0.61 bsfc (L)

28.8 fps piston speed (W) great air/fuel mixture

35mpg @ 66mph (L)

The middle line in the graph is at 2350 rpm

-1.59 inch/hg or 95 kpa (W) less pumping losses

3.13 lbs/min air (N/A)

16.80 bsac (W) more power from air

19.5 cycles/sec (W) lower pumping losses, higher kpa at the intake valves

30 a/f ratio (W) lowers pumping losses by increasing higher load needed for the correct fuel amount for power output.

9.5 whp (W) lower power needed for lower mph

0.56 bsfc (W)

22.6 fps piston speed (W) fast enough to promote good air/fuel mixture

53mpg @ 53mph (W)

*Comparing between the two lines.

(W) win

(L) lose

Now there is the third line, the highest in the graph at 1200 rpm.

FAIL

-1.02 inch/hg or 97 kpa (W) low pumping losses, great kpa at the intake valve

10 cycles/sec (L) very low air velocity killing air flow, and causing reversion

11.5 fps piston speed (L) major knock, from slow power stroke, and heat adsorbed into combustion chamber cylinder etc.