09-28-2015, 07:28 AM

09-28-2015, 07:28 AM

|

#1 (permalink)

|

|

Master EcoWalker

Join Date: Dec 2012

Location: Nieuwegein, the Netherlands

Posts: 4,005

Thanks: 1,716

Thanked 2,252 Times in 1,458 Posts

|

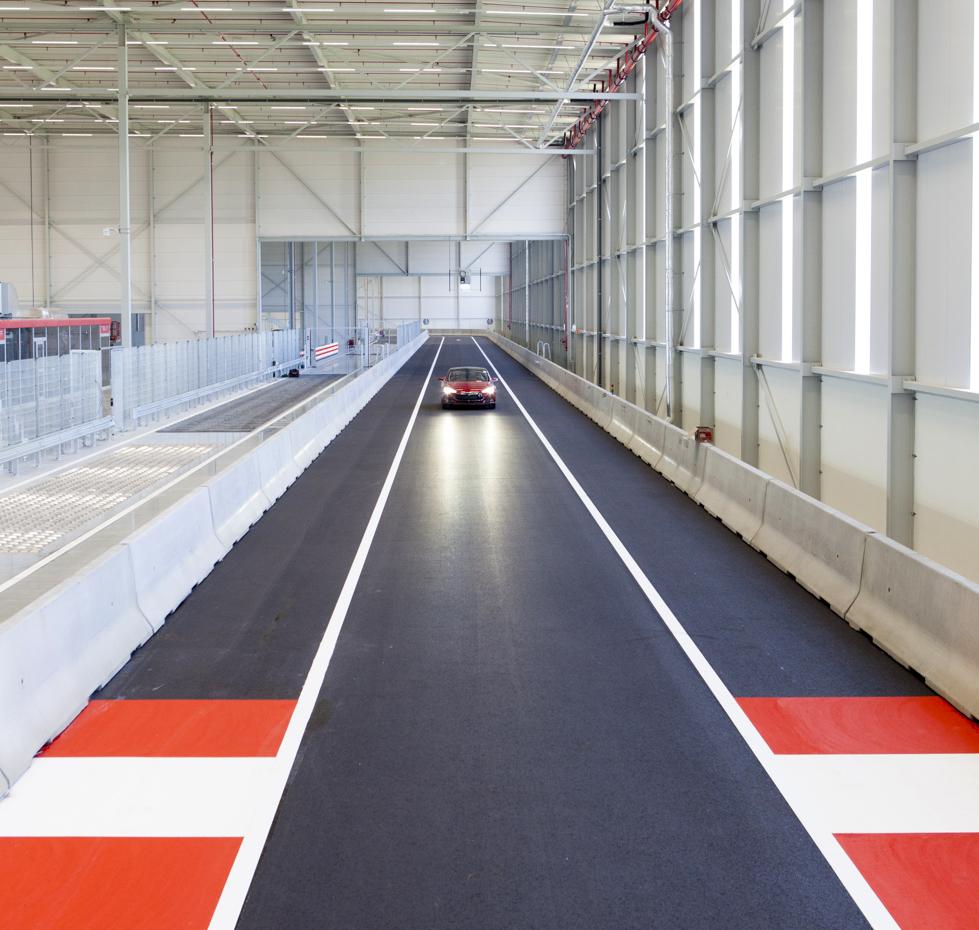

New Tesla factory has an indoor test track

Tesla has recently started the assembly of the Model S for the European market in its new factory in Tilburg, the Netherlands.

It is not much of an assembly though.

The rear engine sub-frame and batteries are shipped separately for safety reasons, but the paint and interior were done in the USA. What still needs to be done is the joining of the frame and pack to the car, wheels on, fluids fill and all round system test.

Yet this greatly enhances Tesla's capacity to deliver cars over Europe.

Key feature of the plant is its indoor test track:

Quote:

... Teslas rumble across teeth-rattling Belgian pavé, before hitting 110kph – just over 60mph – down the back straight.

'Not many manufacturers have a test track inside!' jokes Gilbert Passin, VP of manufacturing in Tilburg and Fremont. 'We have no emissions so it's easy for us, and it gives us consistent, dry conditions.'

|

__________________

2011 Honda Insight + HID, LEDs, tiny PV panel, extra brake pad return springs, neutral wheel alignment, 44/42 PSI (air), PHEV light (inop), tightened wheel nut.

lifetime FE over 0.2 Gigameter or 0.13 Megamile.

For confirmation go to people just like you.

For education go to people unlike yourself.

Last edited by RedDevil; 09-29-2015 at 04:10 AM..

|

|

|

|

|

The Following 4 Users Say Thank You to RedDevil For This Useful Post:

|

|

Today Today

|

|

|

|

Other popular topics in this forum...

Other popular topics in this forum...

|

|

|

|

09-29-2015, 07:10 AM

09-29-2015, 07:10 AM

|

#2 (permalink)

|

|

It's all about Diesel

Join Date: Oct 2012

Location: Porto Alegre, Rio Grande do Sul, Brazil

Posts: 13,042

Thanks: 0

Thanked 1,720 Times in 1,534 Posts

|

Quote:

Originally Posted by RedDevil

It is not much of an assembly though.

The rear engine sub-frame and batteries are shipped separately for safety reasons, but the paint and interior were done in the USA. What still needs to be done is the joining of the frame and pack to the car, wheels on, fluids fill and all round system test.

|

I would hardly consider such a CKD assembly line as a properly-said factory.

Quote:

|

Yet this greatly enhances Tesla's capacity to deliver cars over Europe

|

Does it decrease the expense with import duties or the marine freight costs of the parts shipped from the United States? |

|

|

|

09-29-2015, 07:38 AM

09-29-2015, 07:38 AM

|

#3 (permalink)

|

|

Master EcoWalker

Join Date: Dec 2012

Location: Nieuwegein, the Netherlands

Posts: 4,005

Thanks: 1,716

Thanked 2,252 Times in 1,458 Posts

|

Quote:

Originally Posted by cRiPpLe_rOoStEr

Does it decrease the expense with import duties or the marine freight costs of the parts shipped from the United States?

|

The special measures needed to transport high-voltage battery packs makes it worthwhile to transport those separately from the cars.

The packs need to be kept alive too - if they are in the car too long without being charged they would deteriorate.

The batteryless Model S bodies now ship in sea freight containers in foursomes.

I bet it is much cheaper to do it this way.

__________________

2011 Honda Insight + HID, LEDs, tiny PV panel, extra brake pad return springs, neutral wheel alignment, 44/42 PSI (air), PHEV light (inop), tightened wheel nut.

lifetime FE over 0.2 Gigameter or 0.13 Megamile.

For confirmation go to people just like you.

For education go to people unlike yourself.

|

|

|

|

09-29-2015, 08:07 AM

09-29-2015, 08:07 AM

|

#4 (permalink)

|

|

It's all about Diesel

Join Date: Oct 2012

Location: Porto Alegre, Rio Grande do Sul, Brazil

Posts: 13,042

Thanks: 0

Thanked 1,720 Times in 1,534 Posts

|

Quote:

Originally Posted by RedDevil

The special measures needed to transport high-voltage battery packs makes it worthwhile to transport those separately from the cars.

The packs need to be kept alive too - if they are in the car too long without being charged they would deteriorate.

|

It sounds complicated, but seems to justify the process.

Quote:

The batteryless Model S bodies now ship in sea freight containers in foursomes.

I bet it is much cheaper to do it this way.

|

Wouldn't still make more sense to have the bodyshells made in Europe instead? |

|

|

|

09-29-2015, 07:08 PM

09-29-2015, 07:08 PM

|

#5 (permalink)

|

|

...beats walking...

Join Date: Jul 2009

Location: .

Posts: 6,190

Thanks: 179

Thanked 1,525 Times in 1,126 Posts

|

Cost of shipping is FAR less than the cost of (a) manufacturing facility plus (b) manufacturing employees. Especially if TESLA has designed everything as "plug-n-play" assembly...just bolt the parts together, plug-in the connectors, test...and, wash & wax.

|

|

|

|

|

The Following User Says Thank You to gone-ot For This Useful Post:

|

|

09-29-2015, 09:56 PM

09-29-2015, 09:56 PM

|

#6 (permalink)

|

|

Corporate imperialist

Join Date: Jul 2011

Location: NewMexico (USA)

Posts: 11,312

Thanks: 273

Thanked 3,584 Times in 2,845 Posts

|

If you look closely the track appears to be paved with tax payer dollars.

__________________

1984 chevy suburban, custom made 6.5L diesel turbocharged with a Garrett T76 and Holset HE351VE, 22:1 compression 13psi of intercooled boost.

1989 firebird mostly stock. Aside from the 6-speed manual trans, corvette gen 5 front brakes, 1LE drive shaft, 4th Gen disc brake fbody rear end.

2011 leaf SL, white, portable 240v CHAdeMO, trailer hitch, new batt as of 2014.

|

|

|

|

|

The Following User Says Thank You to oil pan 4 For This Useful Post:

|

|

09-30-2015, 02:57 AM

09-30-2015, 02:57 AM

|

#7 (permalink)

|

|

Master EcoModder

Join Date: May 2008

Location: UK

Posts: 334

Thanks: 16

Thanked 80 Times in 55 Posts

|

That facility opened a couple of years ago to assemble European Model S cars.

Here's a quote from another website as to why...

this is a ‘final assembly‘ facility, meaning they are mostly just re-assembled after leaving Tesla’s Fremont factory in California in order to meet domestic manufacturing/regulatory standards and to avoid extra EU taxation/import tariff rules.

The ‘final assembly‘ process reportedly takes about 2-3 hours per vehicle, but saves about ~10% worth of fees added to the EVs’ pricing. Countries such as Norway and Switzerland do not have these hurdles in place, and thus those vehicles are efficiently shipped complete from the US.

|

|

|

|

09-30-2015, 11:51 AM

09-30-2015, 11:51 AM

|

#8 (permalink)

|

|

Corporate imperialist

Join Date: Jul 2011

Location: NewMexico (USA)

Posts: 11,312

Thanks: 273

Thanked 3,584 Times in 2,845 Posts

|

We have been giving them money for more than a couple years.

__________________

1984 chevy suburban, custom made 6.5L diesel turbocharged with a Garrett T76 and Holset HE351VE, 22:1 compression 13psi of intercooled boost.

1989 firebird mostly stock. Aside from the 6-speed manual trans, corvette gen 5 front brakes, 1LE drive shaft, 4th Gen disc brake fbody rear end.

2011 leaf SL, white, portable 240v CHAdeMO, trailer hitch, new batt as of 2014.

|

|

|

|

10-01-2015, 12:44 PM

10-01-2015, 12:44 PM

|

#9 (permalink)

|

|

Master EcoModder

Join Date: May 2008

Location: Maynard, MA Eaarth

Posts: 7,908

Thanks: 3,475

Thanked 2,953 Times in 1,846 Posts

|

Quote:

Originally Posted by oil pan 4

We have been giving them money for more than a couple years.

|

Tesla has already paid us back, ahead of schedule.

|

|

|

|

|

The Following User Says Thank You to NeilBlanchard For This Useful Post:

|

|

|