sorry. i don't have pictures of EVERY step. let me know if you don't understand any of the steps..... or google the basics of fiberglass and bondo = bodywork

required: plastic sign board, big blue painters tape, LIGHTWEIGHT bondo kit, fiberglass cloth or mat, fiberglass resin, cheap painters brushes, sandpaper(automotive preferred), thick spray primer, spray paint

suggested: a box of latex gloves, paint masks or respirators, spare broken down bumper, coroplast for strength, a lot of time on your hands

difficulty(subjective): 4 out of 10

estimated time: 4 hours minus drying time/ 4 days drying time included

first i taped up all around and inside the indentation. i used black DUCK tape but i would suggest painters tape because of the waxy non stick surface

then i used thin cardboard to template of the LOWER(deeper in) part of the indent and copied onto a thin plastic used for signs INSIDE retail stores (think the large price signs at walmart and target)

next lay the plastic template to the indent. it has to follow the curve of the indent exactly so back up the template with tape or zip-ties to make sure it doesn't move in the process or else the block wont fit in exactly.

i used fiberglass cloth but you could used fiberglass mat. i had a template of the larger area of where the indent is and traced it onto the fiberglass cloth

mix your resin, buy some cheap painters brushes(3 inch wide at least or a set of 3 different sized brushes) and lay some resin evenly into the area. lay the first layer of fiberglass making sure there are no bubbles and top it with another layer of resin. while its still wet lay the second layer and so on and so forth until you get the desired thickness.

this stuff takes forever to dry

after it all dried i layed two salvaged coroplast pieces using the same template from the original plastic backing. i should have cut them shorter on the medial sides of them(the part that was closer to the center of the car). brace the pieces by laying a thin layer of resin before you put the coroplast on top and allowing that to dry. then lay a couple more layers of the fiberglass on top making sure there are no bubbles

then let it dry completely and lay a couple more layers on top of that

and lay the resin

the idea is to get it as close to flush as possible to reduce the amount of bondo to use. i suppose you could lay bondo on after the coroplast stage but the way i did it reduced work and cost.

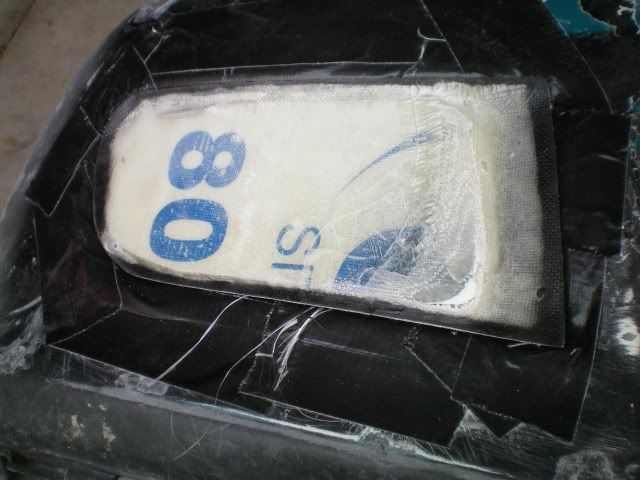

bondo is the next step. lay an even layer of bondo on as evenly as possible. allow this to harden. then sand with 36 or 80 grit sandpaper( this allows the bondo stick to the microscopic teeth). this is why you want to lay it on evenly, to reduce sanding time. time is money.

repeat this process with the bondo until it is FLUSH. make sure you use a sanding block or else it will look and be uneven.

use your hand to feel for high or low spots and add bondo or sand depending on how flush it is.

when you are SURE it is flush, do a final sand with 320grit sand paper and spray on thick-laying primer to fill in the teeth.

do many thin layers and allow to dry.

you can wet-sand with 600grit to get it as smooth as a baby's butt( i didn't do this because i was going with ultra-flat black krylon anyway).

then spray on whichever color you like using thin layers of paint

if you use black primer you can skip this step.

you can do a LAST wet-sand using 2000grit sandpaper to get a more even looking finish(i didn't do that either because i knew it would be exposed to the elements and flying debris)

and viola

(the center GRILL block is just layers of cardboard wrapped with black DUCK tape and a removable piece near the passengers side edge for air to the radiator in the summer)