04-21-2017, 04:44 PM

04-21-2017, 04:44 PM

|

#21 (permalink)

|

|

Master EcoModder

Join Date: Apr 2012

Location: Evensville, TN

Posts: 676

Thanks: 237

Thanked 580 Times in 322 Posts

|

Foam and fiberglass can turn out good, doesn't take that many tools just some patience if you want it to look good when you are done. Look up how to build a foam/fiberglass surfboard, same idea just with a aeroshell.

|

|

|

|

|

The Following 2 Users Say Thank You to aardvarcus For This Useful Post:

|

|

Today Today

|

|

|

|

Other popular topics in this forum...

Other popular topics in this forum...

|

|

|

|

04-22-2017, 12:24 AM

04-22-2017, 12:24 AM

|

#22 (permalink)

|

|

Master EcoModder

Join Date: Aug 2012

Location: northwest of normal

Posts: 29,183

Thanks: 8,288

Thanked 9,046 Times in 7,477 Posts

|

Here is my car with a second-hand wakeboard control arm split and lashed to the roof rack of my car.

They are lightweight tempered aluminum, so they have good stiffness. In practice this would be cut down and transferred to my '58 Beetle. I bought three altogether, for various purposes, from five to eight feet long.

They could be used as lateral or longitudinal formers. |

|

|

|

|

The Following User Says Thank You to freebeard For This Useful Post:

|

|

04-22-2017, 12:43 PM

04-22-2017, 12:43 PM

|

#23 (permalink)

|

|

Master EcoModder

Join Date: Jan 2008

Location: Sanger,Texas,U.S.A.

Posts: 16,445

Thanks: 24,485

Thanked 7,414 Times in 4,804 Posts

|

my angles

Quote:

Originally Posted by canadian_yeti

did I apply the template properly? how to I interpret it to calculate my angles? do I have to have compound curves?

that all wood one on the taco is just gorgeous, but waaay out of my skill and budget lol

|

I wish we had a proper,technical drawing of your truck,showing true lengths.

Anything you do back there is gonna help,but if you really wanted to 'nail it',you'd want something more like a 'blueprint' image to work from.

If you're put off by the compound curves you could maybe create single-curve panels (like Cadillac does with their CTS coupe).It's not ideal,but be maybe 3-X more simple to construct.

__________________

Photobucket album: http://s1271.photobucket.com/albums/jj622/aerohead2/

|

|

|

|

|

The Following User Says Thank You to aerohead For This Useful Post:

|

|

04-24-2017, 08:16 AM

04-24-2017, 08:16 AM

|

#24 (permalink)

|

|

Master EcoModder

Join Date: Apr 2012

Location: Evensville, TN

Posts: 676

Thanks: 237

Thanked 580 Times in 322 Posts

|

Here are the proper technical drawings for the truck, obviously the one with the tires would have the ground plane moved up to be scaled properly based on the drop of his truck.

|

|

|

|

|

The Following 2 Users Say Thank You to aardvarcus For This Useful Post:

|

|

04-26-2017, 01:48 PM

04-26-2017, 01:48 PM

|

#25 (permalink)

|

|

Aero Deshi

Join Date: Jan 2010

Location: Vero Beach, FL

Posts: 1,065

Thanks: 430

Thanked 669 Times in 358 Posts

|

Based on this paper, (page 103/116, or 85) I'd go with this plan. It's about an 8° slope overall which will get you within 5% of the achievable maximum aero drag gain, but you'll drop your aerodynamic lift by 60% or so. In addition, you'll have a lot more practical space under the cap to use, and depending on how you design the back of the cap, you won't have to stoop as far to reach under it. Your height above the tailgate will be about 7.5 inches.

Blue line is the Template, Green is the 8° line, Red....well I think we all know what that would be don't we?

Let me know if you want to do this, I can make accurate drawings that you could take to anyone with a large format printer and get life size templates made.

Last edited by ChazInMT; 04-26-2017 at 01:59 PM..

|

|

|

|

|

The Following 2 Users Say Thank You to ChazInMT For This Useful Post:

|

|

04-26-2017, 03:09 PM

04-26-2017, 03:09 PM

|

#26 (permalink)

|

|

EcoModding Lurker

Join Date: Apr 2017

Location: ontario, canada

Posts: 31

Thanks: 6

Thanked 9 Times in 6 Posts

|

Blue line is the Template, Green is the 8° line, Red....well I think we all know what that would be don't we?

actually no im not sure what the red would be. a guess would be the outline of a cap, but it doesn't follow that 8deg slope you mentioned. I apologize for the ignorance, but I am VERY green to all this aero stuff. I would love the technical drawing for it. would you want any $$$ for it?

I would like to thank everyone for their input. I'm very grateful. I feel like I should take some intro to aerodynamics type courses to keep up with some of this stuff lol

|

|

|

|

04-26-2017, 04:16 PM

04-26-2017, 04:16 PM

|

#27 (permalink)

|

|

Master EcoModder

Join Date: Aug 2012

Location: northwest of normal

Posts: 29,183

Thanks: 8,288

Thanked 9,046 Times in 7,477 Posts

|

Quote:

|

actually no im not sure what the red would be.

|

4.7 Pickup truck model with 3D curved Aerocap

==> http://csus-dspace.calstate.edu/bits...d-finished.pdf<==

Where's the Blink tag when you need it.

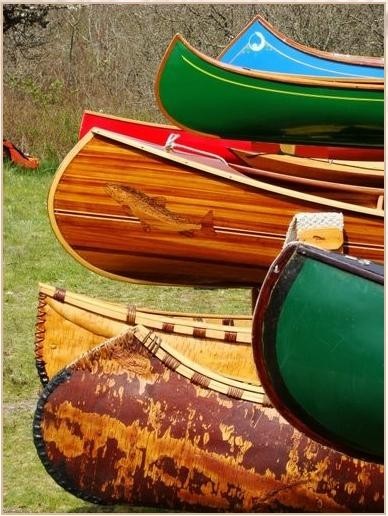

Everybody obsesses about that profile. Spend some time looking at wooden boats on Guns Oil & Dirt

I could go on and on...

|

|

|

|

|

The Following User Says Thank You to freebeard For This Useful Post:

|

|

05-01-2017, 12:05 AM

05-01-2017, 12:05 AM

|

#28 (permalink)

|

|

EcoModding Lurker

Join Date: Apr 2017

Location: Nebraska

Posts: 13

Thanks: 1

Thanked 6 Times in 5 Posts

|

I talked to a local plastics manufacturer who suggested using polycarb rather than acrylic because it's waaay more durable and easier to drill into. Hail damage is a strong consideration, as well as for liability reasons if the acrylic somehow cracks and pieces fly off the back onto following vehicles. The major downside of polycarbonate is that it is somewhat more of a process to heat-bend into shape. This is only because it has some moisture in it that will make poor bends look like they're 'blistering' as the water vapor tries to escape. The simple solution is to bake it first or leave it out in the sun over a black surface for a few hours to get the moisture out. It also gives off toxic fumes when laser-cut, if you care at all. Also, I learned that extruded acrylic sheet is not good for drilling into and doesn't heat-bend as well as cast acrylic sheet. But at the price point of cast acrylic sheet you might as well just go for polycarb. I was quoted $126 for a standard, uncut 48"x96"x1/8" sheet of clear polycarbonate, plus about $10 if I want some hue to it. I recommend getting smoked/greyed/bronzed to try to match your window tint (aesthetics), obfuscate UV yellowing, and to avoid constructing a mobile greenhouse. Also, the professional I talked to suggested taking advantage of the bendy material property of base sheet to avoid having to heat-bend each curve, as in some curves can be done by just warping it into form and bolting it down to the frame. Potentially these kinds of pre-loaded forces in the body of the shell could also add to its rigidity. I guess we'll find out how well all this works once I try it in the next couple weeks. I'm making an aerocap as my first ecomodding project, too, right after finals week is over (I'm a mechanical engineering major). I'd been intending to use a similar construction technique for a few weeks before I found this thread, except I definitely intend to use polycarbonate.

Why 3/4" rather than 1/2" conduit? What kind do you plan to use? EMT, IMT, or Rigid? Dirt cheap EMT really entices me but scares me since it's rolled not extruded tube. I'd be afraid it would buckle, and not being threaded also worries me.

The red curve in the above image appears to refer to the tangent curve from the plane of the roof to the approximate intersection of the 8° line with the plane of the tailgate.

I don't understand why 8° is being suggested, other than for alleged cargo volume improvement and less lift. The heresy of suggesting something other than 12° like the Holy Theses have commanded! Also imo it's prettier to have the trailing edge of the shell as vertically close to the top of the tailgate as possible unless you intend to have an eave/overhang. With other opaque projects, like with the infamous, beautiful, Wooden Taco Topper, the slope was pretty low presumably so that the driver could still see out the window at the boat's keel, but obviously that doesn't apply to us.

Personally, I'm going with the "Holy 12°" for mine. I don't intend to hijack this thread with discussion about my personal project, because I intend to make my own thread once I start construction. Briefly, I've already made a quick 3d sketch in Autodesk Inventor (my go-to CAD), and the 12° works well for me because I don't care about rear lift since my beloved '06 Ridgeline is FWD over ~15mph (pls do not pollute this thread with criticism of my choice of quality utilitarian vehicle - that dead horse belongs on ridgelineownersclub.com - and it was inexpensive after all the fanboys upgraded to the 2017 remake... so far with my driving style and no mods I get ~20mpg for both city and highway but I don't doubt both will increase 3-6mpg by the time I'm done with all my planned mods). Also, since my box walls are so tall, there is only 1.5" between the lowest point of my aerocap's trailing edge and the rear point of the box walls, while the widest point, over the shorter tailgate (the engineers assumed everyone would get a tanoe), it has like a 3.5" gap, which I've obfuscated by including a slight Kamm-ish overhang. The quick model I made is compound sloping on the sides as well, just because that's what is intuitive to match the sides of the RL's box. So far the slopes are straight lines rather than convex because it would be easiest to construct and I've yet to be convinced of a significant advantage of either convex or concave other than following those damn teardrop templates to the T or for aero-aesthetic. Same goes for the corners joining the top sheet to the side sheets, whether I should leave them angular for easy fabrication and intentional flow separation or to gently round them for that dubious aero aesthetic that would take many hours with a heat gun and potentially 'blister' the polycarb. I can't yet post links to my little photobucket, but it's under the same username, if anyone's curious.

Again, I don't want to hijack this thread so please answer in the context of OP's project  |

|

|

|

|

The Following 2 Users Say Thank You to Auptimist For This Useful Post:

|

|

05-01-2017, 12:17 PM

05-01-2017, 12:17 PM

|

#29 (permalink)

|

|

EcoModding Lurker

Join Date: Apr 2017

Location: ontario, canada

Posts: 31

Thanks: 6

Thanked 9 Times in 6 Posts

|

no worries, I appreciate the input as hail and "rolling greenhouse" is something I never really considered.

so does the blue line represent a 12deg slope?

|

|

|

|

05-01-2017, 03:37 PM

05-01-2017, 03:37 PM

|

#30 (permalink)

|

|

EcoModding Lurker

Join Date: Apr 2017

Location: Nebraska

Posts: 13

Thanks: 1

Thanked 6 Times in 5 Posts

|

The blue curve section should be near 12° but I wouldn't put too much faith in those templates (don't fight me on this, guys, I'm sure they're great...). I would just measure the cab height and do some trig. I don't want to sound pretentious at all but here's the procedure to do it by hand if you don't feel like measuring a bit of CAD (which is what I did considering my goofy box sides):

To get the vertical displacement of the end of the shell (truncating the eave/overhang) from the rear of the tailgate:

h_rear = h_cab - box_length * tan(Θ)

From what I understand from other truck threads (I think I've read most of them at this point), the measurements of the simplified flat-profile shell also work for those that are curved to be tangent to the cab roof. Allegedly, so long as you follow the Kamm principle and don't round the rear edge to be tangent to the back of the tailgate, you can get away with a convex shell without significant flow separation even though it clearly is more than 12° past the midpoint. Like I said earlier, I am not yet convinced convexity is worth that flow separation risk and extra effort?

Still definitely curious about your frame choices, as to diameter and EMT vs. Rigid or IMT.

Last edited by Auptimist; 05-01-2017 at 05:17 PM..

Reason: consistency of abbreviations

|

|

|

|

|

The Following User Says Thank You to Auptimist For This Useful Post:

|

|

|