05-02-2017, 12:34 PM

05-02-2017, 12:34 PM

|

#31 (permalink)

|

|

EcoModding Lurker

Join Date: Apr 2017

Location: ontario, canada

Posts: 31

Thanks: 6

Thanked 9 Times in 6 Posts

|

I am beyond a noob. I need to start doing more reading and brush up on my math, cause I'm barely following what you're saying at this point. I have no idea what EMT or rigid IMT is. I only chose 3/4" electrical conduit pipe because I saw a thread with a crew cab f250 on here, and that's what the member used. its also because I happened to come into about 10 6'-8' lengths of it for free through my work. so it was also a convenience thing.

Back to how ignorant I am to all of this, I was only first considering a convex cap because that's what most members had done with their trucks, in following the template. Although I had seen a couple members to flat/straight line caps with rounded edges. I joined this forum and want to do these mods out of necessity. Budget and fuel savings are the biggest reasons. I also mainly started this thread because there were things I was unsure about and can really only afford to do this once. So far, the more this thread goes on, the more I feel over my head. Not to say its any member's fault, its just showing that I really have no idea what I'm doing when it comes to the more technical part of this stuff.

|

|

|

|

|

The Following User Says Thank You to canadian_yeti For This Useful Post:

|

|

Today Today

|

|

|

|

Other popular topics in this forum...

Other popular topics in this forum...

|

|

|

|

05-02-2017, 01:42 PM

05-02-2017, 01:42 PM

|

#32 (permalink)

|

|

Master EcoModder

Join Date: Apr 2012

Location: Evensville, TN

Posts: 676

Thanks: 237

Thanked 580 Times in 322 Posts

|

The stuff you got is EMT if it has a thin wall and isn't threaded.

It is easy to get confused, as many people have many different ideas about what and how to build an aerodynamic bedcover. This is mainly because there is no one right answer. Even some of the "wrong" answers that go against everything everyone suggested so far are better than no bed cover. I built mine the way I wanted (matched to AST-II in side view) out of the materials I wanted (foam/fiberglass). When I build my next one I plan to build it differently (AST-II in both plan and taper view, aluminum structure).

You get the benefit of doing the same, decide how you want to build it that best matches your needs, desires, and skill set and based on what design balancing complexity, utility, and aerodynamics. I will say that copying what other members have completed and proven to work probably is easier than plowing new ground.

|

|

|

|

05-02-2017, 04:13 PM

05-02-2017, 04:13 PM

|

#33 (permalink)

|

|

EcoModding Lurker

Join Date: Apr 2017

Location: ontario, canada

Posts: 31

Thanks: 6

Thanked 9 Times in 6 Posts

|

Quote:

Originally Posted by aardvarcus

I will say that copying what other members have completed and proven to work probably is easier than plowing new ground.

|

that's basically what I was hoping to do. ive considered a version and method similar to yours. as well as considering a few others |

|

|

|

05-02-2017, 08:37 PM

05-02-2017, 08:37 PM

|

#34 (permalink)

|

|

Master EcoModder

Join Date: Aug 2012

Location: northwest of normal

Posts: 29,432

Thanks: 8,375

Thanked 9,129 Times in 7,538 Posts

|

The outline of the cab and the bed side-rails are defined. The profile at the tailgate is your preference. That's half your pieces. The others can be longitudinal stringers.

Get a tubing bender and you're ready to get started.

|

|

|

|

05-06-2017, 12:35 PM

05-06-2017, 12:35 PM

|

#35 (permalink)

|

|

Master EcoModder

Join Date: Jan 2008

Location: Sanger,Texas,U.S.A.

Posts: 16,539

Thanks: 24,520

Thanked 7,439 Times in 4,819 Posts

|

unsure

Quote:

Originally Posted by canadian_yeti

I am beyond a noob. I need to start doing more reading and brush up on my math, cause I'm barely following what you're saying at this point. I have no idea what EMT or rigid IMT is. I only chose 3/4" electrical conduit pipe because I saw a thread with a crew cab f250 on here, and that's what the member used. its also because I happened to come into about 10 6'-8' lengths of it for free through my work. so it was also a convenience thing.

Back to how ignorant I am to all of this, I was only first considering a convex cap because that's what most members had done with their trucks, in following the template. Although I had seen a couple members to flat/straight line caps with rounded edges. I joined this forum and want to do these mods out of necessity. Budget and fuel savings are the biggest reasons. I also mainly started this thread because there were things I was unsure about and can really only afford to do this once. So far, the more this thread goes on, the more I feel over my head. Not to say its any member's fault, its just showing that I really have no idea what I'm doing when it comes to the more technical part of this stuff.

|

After 40-years of this I'm never sure of a thing.But the chance to succeed always trumps any apprehension.

Dyson said that he never learned anything from his successes,only his failures.

Elon Musk is paying over $67 an hour for this stuff.Failing your way to victory is cheaper in the long game.

__________________

Photobucket album: http://s1271.photobucket.com/albums/jj622/aerohead2/

|

|

|

|

|

The Following 2 Users Say Thank You to aerohead For This Useful Post:

|

|

05-10-2017, 03:11 PM

05-10-2017, 03:11 PM

|

#36 (permalink)

|

|

EcoModding Lurker

Join Date: Apr 2017

Location: Nebraska

Posts: 13

Thanks: 1

Thanked 6 Times in 5 Posts

|

Materials info dump: While looking at conduit at Menards I found that the Rigid/IMT conduit has the same screw threads as the steel water pipe of the same diameter, which happens to be cheaper and sturdier anyway. From what I gather, the only difference is that conduit is post-processed a bit more to be smoother inside so as to not damage any cables. Another cost saving measure would be to use Black rather than galvanized pipe (looks better anyways since most cars have some black plastic to match already). Then I checked Ace and found that the same exact black pipe (Wheatland brand) is cheaper than their EMT and a third of the price, at $2.49/10ft, which is just nuts. Definitely suggest thin water pipe over EMT conduit because it's much stronger (won't buckle or split at the seam) and can be threaded rather than just connected with compression fittings. It's harder to bend into shape, but that's kinda the point isn't it. I'll just use Tee intersections and 45° fittings and such instead, since there's a wealth of threaded plumbing fittings. I'm gonna buy a tap/die to thread the cut-sections of odd lengths, then I might sell it again once I'm done with it.

|

|

|

|

05-10-2017, 04:49 PM

05-10-2017, 04:49 PM

|

#37 (permalink)

|

|

Master EcoModder

Join Date: Aug 2012

Location: northwest of normal

Posts: 29,432

Thanks: 8,375

Thanked 9,129 Times in 7,538 Posts

|

Welcome to Ecomodder...

Why would you pay new prices for tubing?

Why would you not look for aluminum tubing?

Why would you use threaded couplers instead of glued-and-riveted internal lugs?

|

|

|

|

05-10-2017, 05:36 PM

05-10-2017, 05:36 PM

|

#38 (permalink)

|

|

EcoModding Lurker

Join Date: Apr 2017

Location: Nebraska

Posts: 13

Thanks: 1

Thanked 6 Times in 5 Posts

|

Thank you for asking questions. Half of throwing ideas at a wall is making sure the wall will bounce them back

Used: I hadn't thought of that and I don't know where to get used tube/pipe.

Aluminum: Generally more expensive and not immediately available at a hardware store. Though I could be convinced to go to a local manufacturer to get a quote. Imo for a 4500lb truck, in my case, the weight of the tubing is a smaller concern than cost and strength. I'd save maybe 10lbs maximum in the switch. Some math: If I'm lucky I'll get a 3-4mpg increase, so a reasonable hope is +3.5mpg. With baseline 19mpg and $2.20/gal ave. in my state, I'd save 1.85 cents per mile. So for every dollar I spend it takes another 55.6 miles to break even. At my budget of $140 (most is for a good polycarb sheet), which I'm already probably going to break, it'll take almost 8k miles to break even. Damn northern oilsands making gas too cheap to properly ecomod

Glued and riveted internal lugs: I hadn't thought of that. I'm not very familiar with this method. I had considered riveted connections when I was looking at EMT. What are the advantages? Screwing something in then gluing it seems easier and perhaps stronger. |

|

|

|

05-10-2017, 10:11 PM

05-10-2017, 10:11 PM

|

#39 (permalink)

|

|

Master EcoModder

Join Date: Aug 2012

Location: northwest of normal

Posts: 29,432

Thanks: 8,375

Thanked 9,129 Times in 7,538 Posts

|

Here's what I like: wakeboard control arms:

I bought three of those five for IIRC $8-10 each. Not tested to destruction yet, but they're very light, stiff and curved.

IDK where to look in Nebraska. Maybe something like Habitat for Humanity. Maybe Goodwill or St. Vinnie's for TV antenna masts, etc.

"Glued and riveted internal lugs" I made that part up. Bicycle frames would have external lugs and brazing. |

|

|

|

|

The Following User Says Thank You to freebeard For This Useful Post:

|

|

05-13-2017, 01:27 PM

05-13-2017, 01:27 PM

|

#40 (permalink)

|

|

Master EcoModder

Join Date: Jan 2008

Location: Sanger,Texas,U.S.A.

Posts: 16,539

Thanks: 24,520

Thanked 7,439 Times in 4,819 Posts

|

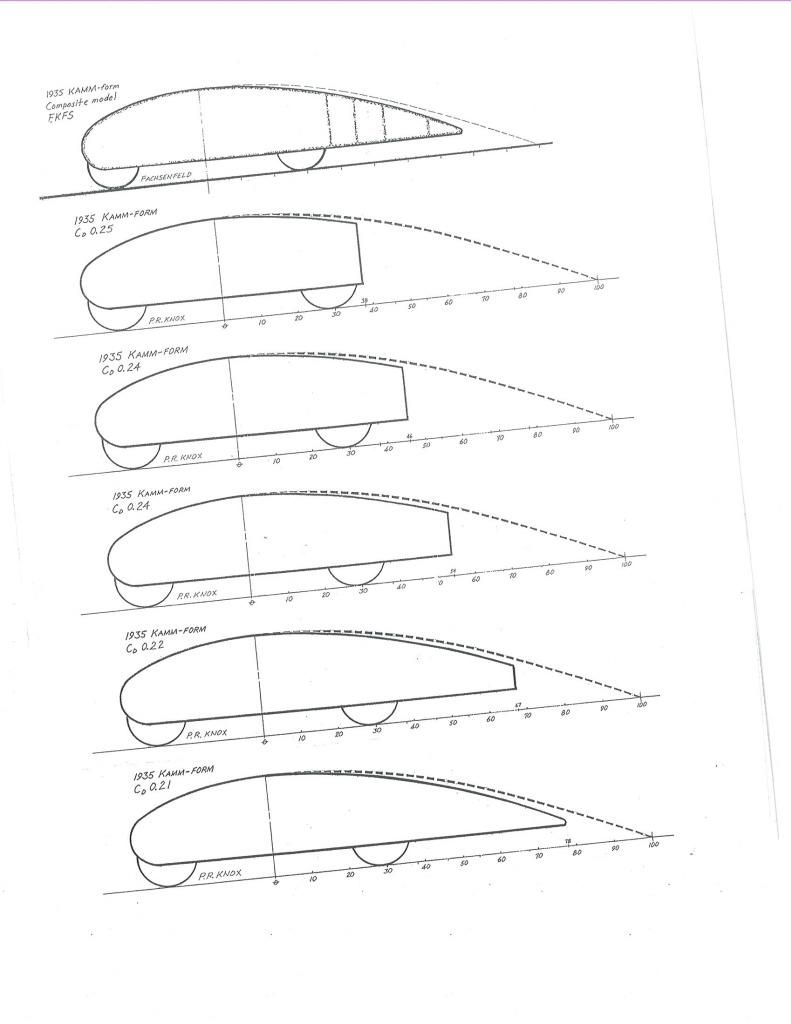

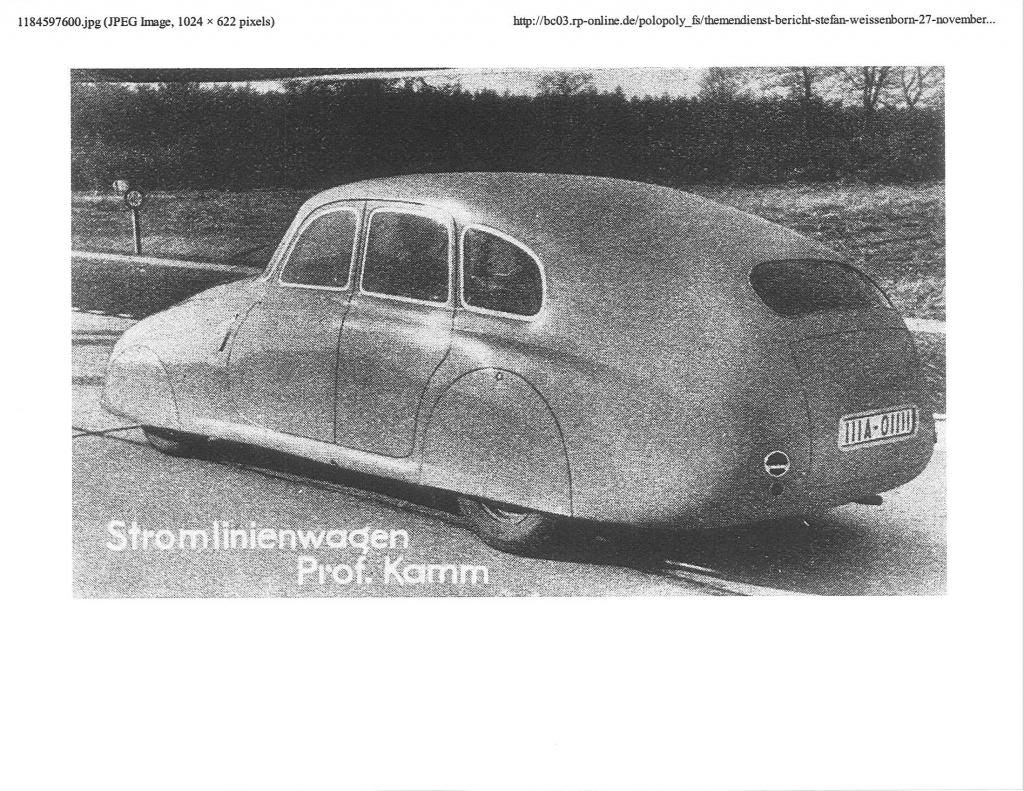

Kamm

Quote:

Originally Posted by Auptimist

The blue curve section should be near 12° but I wouldn't put too much faith in those templates (don't fight me on this, guys, I'm sure they're great...). I would just measure the cab height and do some trig. I don't want to sound pretentious at all but here's the procedure to do it by hand if you don't feel like measuring a bit of CAD (which is what I did considering my goofy box sides):

To get the vertical displacement of the end of the shell (truncating the eave/overhang) from the rear of the tailgate:

h_rear = h_cab - box_length * tan(Θ)

From what I understand from other truck threads (I think I've read most of them at this point), the measurements of the simplified flat-profile shell also work for those that are curved to be tangent to the cab roof. Allegedly, so long as you follow the Kamm principle and don't round the rear edge to be tangent to the back of the tailgate, you can get away with a convex shell without significant flow separation even though it clearly is more than 12° past the midpoint. Like I said earlier, I am not yet convinced convexity is worth that flow separation risk and extra effort?

Still definitely curious about your frame choices, as to diameter and EMT vs. Rigid or IMT.

|

Kamm advocated convexity.

He's remembered for the pragmatism of a limited-length tail truncation.

And while he advocated a clean chop off to the aft-body,he never actually did it in practice,as a concession to aesthetics.

__________________

Photobucket album: http://s1271.photobucket.com/albums/jj622/aerohead2/

|

|

|

|

|