12-19-2015, 08:49 PM

12-19-2015, 08:49 PM

|

#1 (permalink)

|

|

EcoModding Apprentice

Join Date: May 2011

Location: Oregon

Posts: 106

Thanks: 0

Thanked 26 Times in 22 Posts

|

Easy trailer front-end improvement

I don't know if anyone has tried this, not sure what to search for.

I have seen photos of the Bonneville cars with the lip that extends forward, close to the ground, preventing air going under the car and directing it to the side instead. It is a horizontal surface, not the usual vertical front air dam (although that may be present as well, just above it). Can anyone give me the jargon term for that lip?

Anyway I was looking at the front of my trailer. I have a basic 6x12 enclosed trailer, the kind that has a smooth curve from front to side, but a sharp 90 degree corner from front to top. I always want to make a nice smooth radius up there but fabricating it would be a ***** because it would require curving the material in two dimensions. Finally it occurred to me to take that "Bonneville lip" and apply it up there. In other words it would be just a flat piece of rigid material screwed to the top of the trailer (which is also flat in my case) and projecting forward some distance, maybe something like a foot. Assuming the trailer is set up horizontally at the hitch, this lip would simply divide the air into two regions - above it the air would be undisturbed, while below it the air would strike the trailer front and then curve around to the sides (I'm writing as if it was the air moving, rather than the trailer).

If this makes sense, it would be very easy to implement compared to a big round radius up there.

An enhancement to this idea would be an additional curved surface reproducing the front trailer surface, under the lip, but with a more round front rather than flattened as with most trailers. Or maybe just a "V"; whatever is optimal. This would be material curved in one dimension so it would be easy. It would be easy to attach it to the underside of the lip as well.

Has anybody done anything like this?

__________________

|

|

|

|

Today Today

|

|

|

|

Other popular topics in this forum...

Other popular topics in this forum...

|

|

|

|

12-19-2015, 09:31 PM

12-19-2015, 09:31 PM

|

#2 (permalink)

|

|

T-100 Road Warrior

Join Date: Apr 2008

Location: The Woodlands, TX

Posts: 1,921

Thanks: 3,502

Thanked 1,395 Times in 968 Posts

|

__________________

Dark Aero-The world's first aerodynamic single wheel boat tail!

|

|

|

|

|

The Following User Says Thank You to BamZipPow For This Useful Post:

|

|

12-19-2015, 09:59 PM

12-19-2015, 09:59 PM

|

#3 (permalink)

|

|

EcoModding Apprentice

Join Date: May 2011

Location: Oregon

Posts: 106

Thanks: 0

Thanked 26 Times in 22 Posts

|

Yes (thanks), except there is no intention to increase lift or down-pressure.

__________________

|

|

|

|

12-20-2015, 02:32 AM

12-20-2015, 02:32 AM

|

#4 (permalink)

|

|

Master EcoModder

Join Date: Aug 2012

Location: northwest of normal

Posts: 28,733

Thanks: 8,157

Thanked 8,938 Times in 7,380 Posts

|

Quote:

|

Has anybody done anything like this?

|

Do you mean recently?

Or a month ago?

At first I thought you were going to suggest adding a splitter below the tongue. That could work.

posted by aerohead in one of those threads.

|

|

|

|

12-20-2015, 06:30 AM

12-20-2015, 06:30 AM

|

#5 (permalink)

|

|

Master EcoModder

Join Date: May 2009

Location: Australia

Posts: 1,510

Thanks: 325

Thanked 452 Times in 319 Posts

|

You don't have to enclose the sides, an open sided half pipe will work nearly as well. There's a company actually making and selling them like that.

|

|

|

|

12-20-2015, 12:22 PM

12-20-2015, 12:22 PM

|

#6 (permalink)

|

|

EcoModding Apprentice

Join Date: May 2011

Location: Oregon

Posts: 106

Thanks: 0

Thanked 26 Times in 22 Posts

|

I saw those two threads. Unless I missed something, I saw nothing in those threads about using a splitter on the top front edge. I like nice rounded fronts like in those threads, but you can't fabricate them with a piece of plywood.

The point of this thread is to get some aero improvement with little effort.

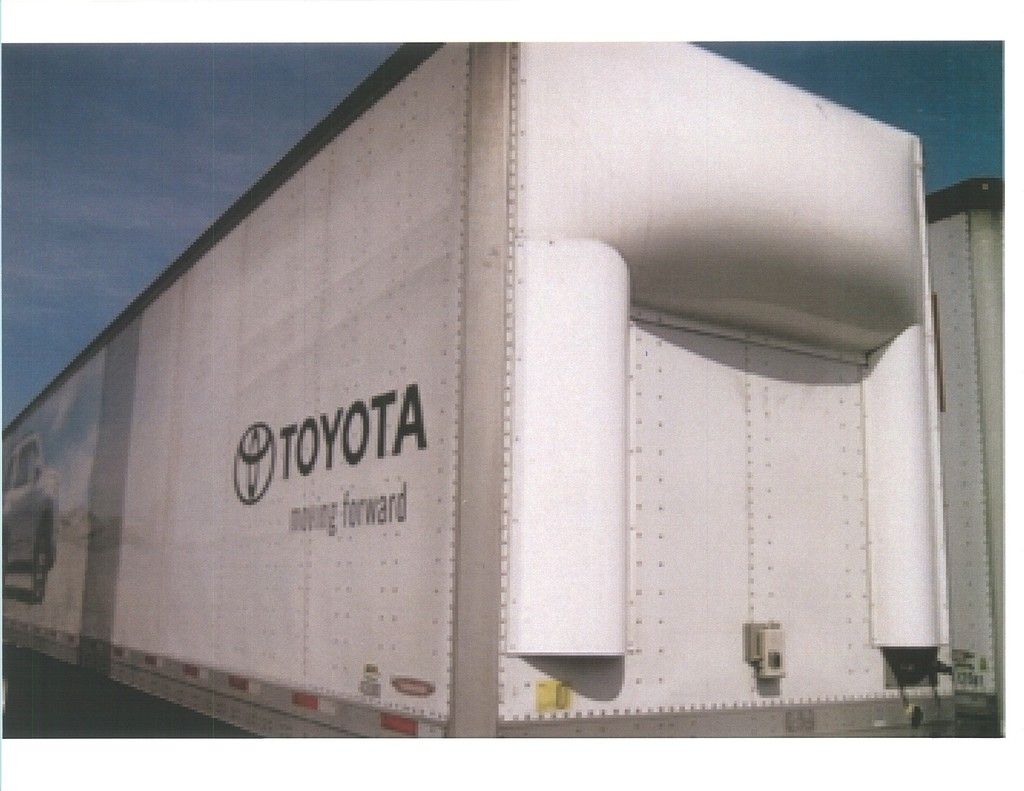

I should add one point. A completely rounded trailer front will direct some of the air that hits it to the sides and some to the top. My guess is that this is ideal. Using just a splitter on a trailer that I described will direct the air to the sides, but none to the top; I'm guessing this is somewhat less of an improvement. The photo you enclose directs the air that hits near the corners, to the sides and to the top. However it depends on having a tractor close in front, as any air that could hit the center of the front surface has nowhere to go. So for a car or pickup pulling a trailer, that solution might not work as well?

__________________

Last edited by PaulB2; 12-20-2015 at 12:32 PM..

|

|

|

|

12-20-2015, 12:53 PM

12-20-2015, 12:53 PM

|

#7 (permalink)

|

|

EcoModding Apprentice

Join Date: May 2011

Location: Oregon

Posts: 106

Thanks: 0

Thanked 26 Times in 22 Posts

|

Just to give an example, this is what my trailer looks like up front:

Rounded on the vertical edges, sharp corner on top, and flat roof. An economy trailer. This is primarily what I am talking about.

In looking for this picture I noticed it was difficult to find an example. It seems most trailers for sale these days have a rounded top and the front top corner is a moulded plastic piece, curved in two dimensions. More like this:

Obviously for something like that, slapping a piece of plywood on top to make a splitter is not going to help anything. At least I don't think so.

__________________

Last edited by PaulB2; 12-20-2015 at 01:01 PM..

|

|

|

|

12-20-2015, 01:40 PM

12-20-2015, 01:40 PM

|

#8 (permalink)

|

|

Master EcoModder

Join Date: Aug 2012

Location: northwest of normal

Posts: 28,733

Thanks: 8,157

Thanked 8,938 Times in 7,380 Posts

|

Quote:

I saw those two threads ... I like nice rounded fronts like in those threads, but you can't fabricate them with a piece of plywood.

The point of this thread is to get some aero improvement with little effort.

|

The limit on material choice was not called out in the OP. So slap a sheet plywood on there, it'll make for easy A-B-A testing.

Here is a material called PolyMetal. It is 3mm thick and as stiff as 5/8" plywood. It cost about twice as much. (Now will it be easy and cheap?)

Edit: How do you propose to fasten that mouldy dirt-magnet to your shiny metal trailer?

Last edited by freebeard; 12-20-2015 at 01:46 PM..

|

|

|

|

12-20-2015, 01:53 PM

12-20-2015, 01:53 PM

|

#9 (permalink)

|

|

EcoModding Apprentice

Join Date: May 2011

Location: Oregon

Posts: 106

Thanks: 0

Thanked 26 Times in 22 Posts

|

Screws through the top of course, into the two frame members that are up there. I was thinking of 1/4" plywood, or something similarly light, so if it flies off it won't kill anybody.  But aluminum plate would be a more permanent material.

Yeah, if I used bolts instead of screws, I could do testing more easily.

__________________

|

|

|

|

12-20-2015, 02:07 PM

12-20-2015, 02:07 PM

|

#10 (permalink)

|

|

Master EcoModder

Join Date: Aug 2012

Location: northwest of normal

Posts: 28,733

Thanks: 8,157

Thanked 8,938 Times in 7,380 Posts

|

When it doesn't help and you take it off, then you will have upward facing holes in your roof. You can replace the plywood with neoprene washers and put the screws back.

Else, build a tripod on the tongue and put the splitter on top of it. If you wrap the tripod there will be some additional improvement.

|

|

|

|

|