01-24-2017, 06:13 PM

01-24-2017, 06:13 PM

|

#51 (permalink)

|

|

EcoModding Lurker

Join Date: Jan 2011

Location: Augusta, ME

Posts: 45

Thanks: 2

Thanked 12 Times in 11 Posts

|

It is quite amazing how little holds these things together. Thanks for digging that up.

I can't imagine what a crash test would reveal.... hence building mine out of welded 1"steel tubing.

|

|

|

|

Today Today

|

|

|

|

Other popular topics in this forum...

Other popular topics in this forum...

|

|

|

|

01-24-2017, 09:02 PM

01-24-2017, 09:02 PM

|

#52 (permalink)

|

|

Master EcoModder

Join Date: Aug 2012

Location: northwest of normal

Posts: 29,401

Thanks: 8,362

Thanked 9,123 Times in 7,533 Posts

|

No doubt they do some internal, proprietary testing.

Here is what I would use; it goes by commercial names like Polymetal and Alumapanel. It is a 3-6mm core of recycled thermoplastic with a .007-.014" aluminum skin on one or both sides. It is used, for example, in commercial signage.

The material I experimented with can be sheared, rolled, and braked by hand and is about as stiff as 5/8" plywood at 10% the weight. I propose a 45° roll followed by a braked edge, butted together to make a radiused edge. The seam across the radius is held by a flexible H-molding. |

|

|

|

01-26-2017, 01:59 PM

01-26-2017, 01:59 PM

|

#53 (permalink)

|

|

EcoModding Lurker

Join Date: Jan 2011

Location: Augusta, ME

Posts: 45

Thanks: 2

Thanked 12 Times in 11 Posts

|

I like that product a lot.. but it's pricey and hard to get ahold of. I think there's a place an hour from here that sells it. Probably double the cost or more of what I'm thinking of doing.

Part 9

|

|

|

|

|

The Following User Says Thank You to benfroggg For This Useful Post:

|

|

01-26-2017, 03:13 PM

01-26-2017, 03:13 PM

|

#54 (permalink)

|

|

Master EcoModder

Join Date: Aug 2012

Location: northwest of normal

Posts: 29,401

Thanks: 8,362

Thanked 9,123 Times in 7,533 Posts

|

What you see in the pictures cost me $25 dollars. It would be enough to do the front corners of the cab-over.

Local to me it's Multicraft Plastics. They have three prices: Walked in off the street

local busines oneses

wholesale So who do you know? Not that is makes a difference at this point. You can add onto what you have with stove-pipe tin.

Edit: Twice the cost and one-quarter the work. It's pre-finished on one or both sides.

Last edited by freebeard; 01-26-2017 at 03:46 PM..

|

|

|

|

01-26-2017, 09:48 PM

01-26-2017, 09:48 PM

|

#55 (permalink)

|

|

EcoModding Lurker

Join Date: Jan 2011

Location: Augusta, ME

Posts: 45

Thanks: 2

Thanked 12 Times in 11 Posts

|

I thought you were talking about using that for the entire outside skin, not just the rounded corners.

This is the place I'm thinking of. They dont list the product on their site. Plastic Supply of Maine

If it's just small pieces, I could probably snag them on ebay cheap enough. Aluminum vent pipe is what I was thinking of going with, but it's really too thin to hold it's shape on it's own. I was thinking of putting something in behind it as a backer....

I'm from Augusta, ME. There are a couple of sign shops near by. I'll have to make some calls when I get ready to do those corners. |

|

|

|

01-26-2017, 11:50 PM

01-26-2017, 11:50 PM

|

#56 (permalink)

|

|

Master EcoModder

Join Date: Aug 2012

Location: northwest of normal

Posts: 29,401

Thanks: 8,362

Thanked 9,123 Times in 7,533 Posts

|

Quote:

|

I thought you were talking about using that for the entire outside skin, not just the rounded corners.

|

Well, I'd do a monocoque shell less the steel frame. At ~$100 for a 4x8 sheet, with no expenses for finish work. (and clean-up).

But rolled strips like I showed could have been structural members on the edges with quarter-spherical metal caps welded to angle stock instead of square tubing.

Posting in Ecomodding Central, you didn't get some of the input you'd have had (from other posters about the Dryden van) by posting in Aerodynamics before you even bought materials. |

|

|

|

01-27-2017, 01:50 PM

01-27-2017, 01:50 PM

|

#57 (permalink)

|

|

EcoModding Lurker

Join Date: Jan 2011

Location: Augusta, ME

Posts: 45

Thanks: 2

Thanked 12 Times in 11 Posts

|

I started the project before posting about it here. I had a picture in my head of what I wanted, based on a couple of factors. The main factor is experience. The other is cost.

I know how to work with the materials I'm using already. I had a lot of the bits that would be needed to make the project work as well as control the cost. I had all the tools I needed to build it this way. I knew the sources of all my materials and could plan for the budget.

As with all things engineering, there are always more elegant solutions for problems.... but in this case, experience and function over form won.

Perhaps for a smaller project down the road (such as a small aero trailer I want to build) I'll go for your solution. Especially once I've gained some experience working with the material on my aero corners.

|

|

|

|

01-27-2017, 02:36 PM

01-27-2017, 02:36 PM

|

#58 (permalink)

|

|

Master EcoModder

Join Date: Aug 2012

Location: northwest of normal

Posts: 29,401

Thanks: 8,362

Thanked 9,123 Times in 7,533 Posts

|

Please don't feel the need to be defensive. You're building something, I just like to talk.  I understand the limitations you work with (ceiling height, etc). and you can't wire-weld Polymetal.

I watched your solar panel video with interest. I want to put a 3x12ft collector on my flat roof.

I'm (slowly) restoring a Westfalia utility trailer. It is a 2x3x4ft plywood box on a T-frame with independent suspension. I may replace the box with a teardrop capsule, a single axle version of this:

|

|

|

|

01-27-2017, 06:13 PM

01-27-2017, 06:13 PM

|

#59 (permalink)

|

|

EcoModding Lurker

Join Date: Jan 2011

Location: Augusta, ME

Posts: 45

Thanks: 2

Thanked 12 Times in 11 Posts

|

Nice, I have a friend with a fully restored Wesfalia bus. Super cool.

I've always wanted to build an aero trailer that had a flexible union that actually touched the towing vehicle, similar to how Amtrak trains have rubber joints between cars. Thus the trailer is a full boat tail... improving MPG's as well as storage.

The solar heating panel does work well... the application is key, though. You have to find a solution to close the vent during the night, or much of the energy gains find their way back out again. Mine works well because the building it's in pretty much doesn't get used after dark. Just daytime use... so it rides 10-20degrees above outdoor temps with incomplete insulation in the building. Not to shabby.

Back to the motorhome...

Today I was thinking about how to do the boat tail. First I was thinking folding aluminum panels (former beds from the pop up trailer to utility trailer build video) mounted on the back leading edges. Then some nifty arrangement to have a folding panel to fill in the top. This would end up looking exactly like what big rigs are using now.

But that has some problems... firstly, it doesn't fill in the large hole in the back of the boat tail. Secondly, it doesn't offer any more storage. Third, the taillights couldn't easily be relocated, so the tail would have to be above the lights... thus losing 20% of boat tail potential.

So instead I'm thinking of something that goes into the hitch. Weld up a light 3/4" tube frame that sits 1" or less from the back of the camper body. Closed on all sides including the back. A small access door provides storage for a couple stage props (lowrider bikes). Then use the hitch wiring to plug in the boat tail which would have built in tail lights. Mount the plate on the rear bumper or just below, etc.

Only real issue is getting it on and off. There has to be an elegant solution to do this... I was thinking of some folding wheels or something.

Best yet, I can get the motorhome on the road/inspected before I build it.

What are your thoughts on that?

|

|

|

|

01-28-2017, 02:38 AM

01-28-2017, 02:38 AM

|

#60 (permalink)

|

|

Master EcoModder

Join Date: Aug 2012

Location: northwest of normal

Posts: 29,401

Thanks: 8,362

Thanked 9,123 Times in 7,533 Posts

|

many and varied.

I suggest using the Search function; using criteria like 'hitch mount'. You will find build threads, mostly for sedans. Look through some of the threads that sound interesting. Eventually you'll run across archetypal things like the Dryden truck

http://ecomodder.com/forum/showthread.php/most-aerodynamic-cargo-box-18000-3.html#post248933

http://ecomodder.com/forum/showthread.php/most-aerodynamic-cargo-box-18000-3.html#post248933

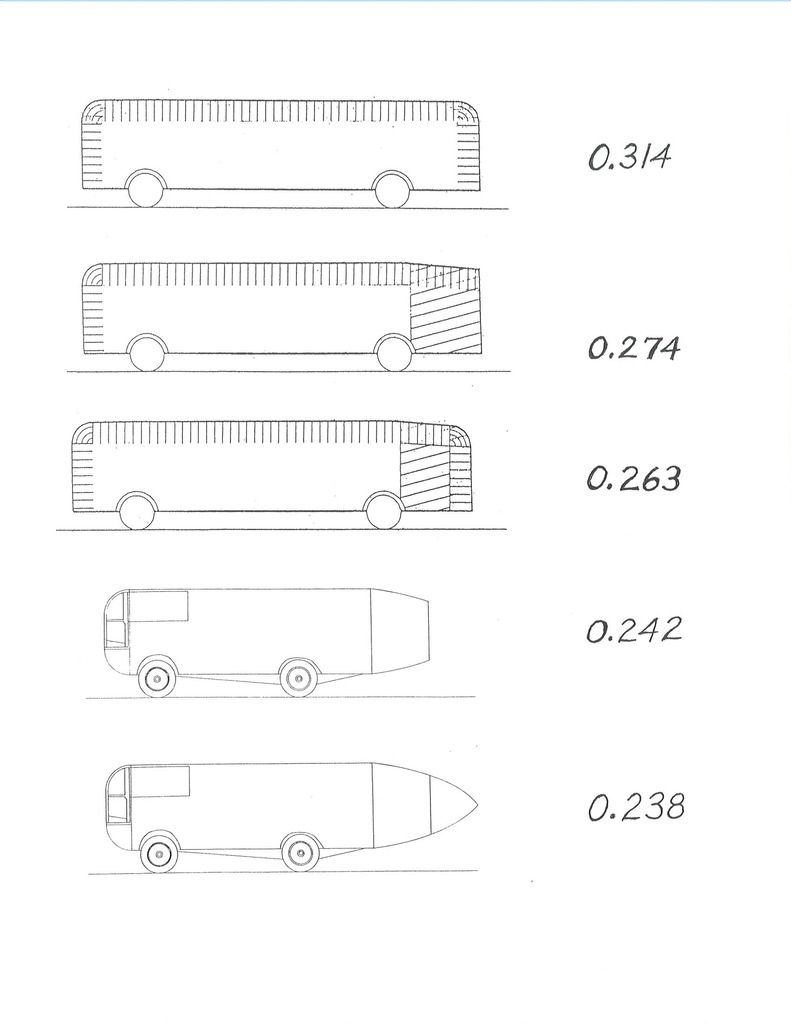

Or aerohead's side views

You are right about an incomplete trailer tail. But an un-bulkheaded truncation can act as a 'box cavity' with beneficial effect.

Between a hitch mount and a full trailer, there is the single-wheel trailer. BamZipPow's as an example.

Here is my own design for a panel truck I owned:

It would have a solid floor and inflated tubes or fiberglass rods to shape the top and sides. In your case a double hinged floor and pop-out rear bulkhead might work. One set of tail lights.

|

|

|

|

|