10-10-2009, 08:58 AM

10-10-2009, 08:58 AM

|

#241 (permalink)

|

|

Master EcoModder

Join Date: May 2009

Location: Charlotte NC / York SC

Posts: 728

Thanks: 120

Thanked 56 Times in 52 Posts

|

Yes, when lowered enough the air can't fit under the car and has to go around/over.

Look at the ground clearance, 50MM/ 2". Let me know anywhere off track that that wouldn't scrape like mad.

Many states have a 4" min ground clearance law as well.

We experimented in my go-karting days with an adjustable "skirt" that basically rubbed the ground. picked up some aero benefit from it but every loose bolt or tire marble jammed under the durn thing.

|

|

|

|

Today Today

|

|

|

|

Other popular topics in this forum...

Other popular topics in this forum...

|

|

|

|

10-10-2009, 09:50 AM

10-10-2009, 09:50 AM

|

#242 (permalink)

|

|

Master EcoModder

Join Date: Dec 2007

Location: Upstate SC

Posts: 1,088

Thanks: 16

Thanked 677 Times in 302 Posts

|

Lowering helps to reduce Cd when you have a rough and turbulent underside that you want to divert the air flow away from. Where the added drag of diverting the air the additional distance to the sides of the vehicle is less than the drag that the same air would have produced had it gone under the vehicle and interacted with the rough underside. If you have a totally smooth underside, the ideal would be raise the vehicle high enough to reduce some of the ground effect compression of the air passing under the vehicle, as they do on some of the solar racers and with the early Aptera prototypes (before they lowered them to handle the mechanicals when they switched to FWD, raising the Cd). The solar racers have very skinny wheels to keep the exposed wheel surface area to a minimum.

|

|

|

|

10-10-2009, 10:11 AM

10-10-2009, 10:11 AM

|

#243 (permalink)

|

|

Master EcoModder

Join Date: May 2008

Location: Maynard, MA Eaarth

Posts: 7,908

Thanks: 3,475

Thanked 2,953 Times in 1,846 Posts

|

Hi,

I'm pretty sure that Mike is right -- what he mentions about having a smooth underside is confirmed by the Hucho book in referencing the Schlör Pillbug. With that amazing car (Cd of just 0.13) there was an ideal height -- if it was lower or higher then the Cd was adversely affected. (I can't quote it, but I plan on buying the Hucho book soon -- I had it from the MIT library a while back.)

I'm hoping to do a belly pan, and I'm not willing to give up any ground clearance -- driving on New England roads require at least as much ground clearance that I currently have.

|

|

|

|

10-10-2009, 01:27 PM

10-10-2009, 01:27 PM

|

#244 (permalink)

|

|

Master EcoModder

Join Date: May 2008

Location: Maynard, MA Eaarth

Posts: 7,908

Thanks: 3,475

Thanked 2,953 Times in 1,846 Posts

|

Last edited by NeilBlanchard; 10-10-2009 at 02:19 PM..

|

|

|

|

10-21-2009, 09:57 PM

10-21-2009, 09:57 PM

|

#245 (permalink)

|

|

Master EcoModder

Join Date: May 2008

Location: Maynard, MA Eaarth

Posts: 7,908

Thanks: 3,475

Thanked 2,953 Times in 1,846 Posts

|

Hi,

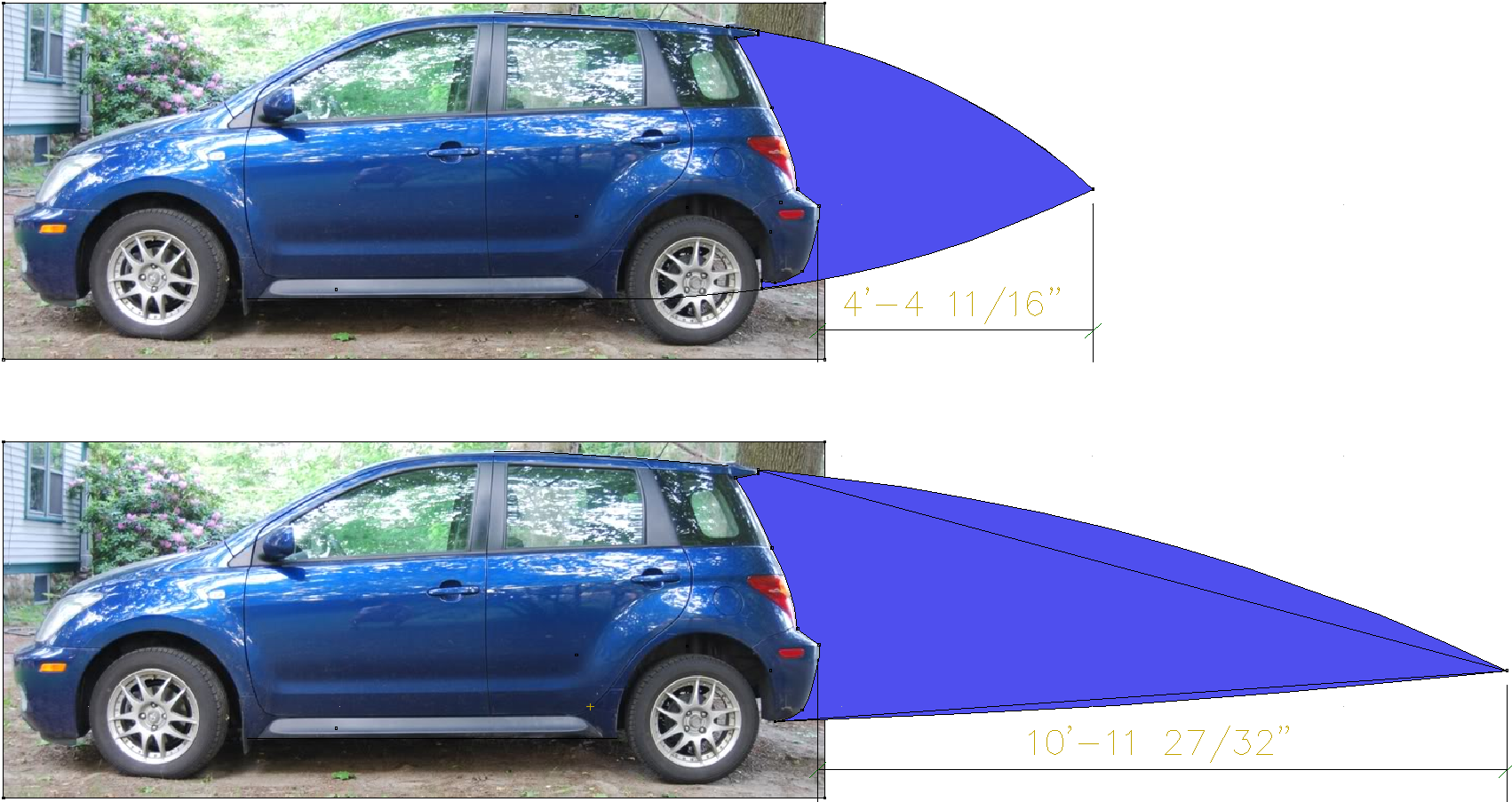

All this talk about boattails has made me contemplate this for my xA. Would this profile work well?

|

|

|

|

10-21-2009, 11:03 PM

10-21-2009, 11:03 PM

|

#246 (permalink)

|

|

Old Retired R&D Dude

Join Date: May 2008

Location: Woburn Mass USA

Posts: 702

Thanks: 10

Thanked 18 Times in 17 Posts

|

I see you have a couple of little boat-tail side-boards on the rear window sides..

Maybe you could try extending those out a little longer and add a top to it,

like I did on my old CRV?

When I did the rear window and spare tire yarn test, none of them were moving..

It was just dead air on the rear window and spare. I guess the turbulence had moved aft.?.

__________________

Cheers,

Rich

Current ride: 2014 RAV4 LE AWD (24 MPG)

Wife's Pizza Transporter

|

|

|

|

10-21-2009, 11:18 PM

10-21-2009, 11:18 PM

|

#247 (permalink)

|

|

Master EcoModder

Join Date: Dec 2008

Location: Southern WI

Posts: 829

Thanks: 101

Thanked 563 Times in 191 Posts

|

Neil,

The first portion of your boat tail would allow the air to stay attached, but because the flare angle increases sharply towards the rear, I'm inclined to think that the air will most definitely detach before it reaches the end.

ASTM calibration orifices have a similar problem. These are orifices that are used for calibrating flow meters in the lab. We have them at work. Sonic nozzles have a limit on the maximum included angle that the exit cone can open up at.

I believe a total angle of 15° is considered the maximum that a cone could open up and still maintain attached flow.

The Honda Insight, as well as the Prius both has a maximum angle of about 20° or so. I gets correspondingly harder to keep the flow attached at angles steeper than this, although in some cases it *may* be possible.

If I add a boat tail to the Insight someday, I will be sure to keep the maximum angle at 20°, otherwise the downstream side of the tailboat is non-functional after the air separates.

Of course, you *could* build one to your specifications and do tuft testing to see just how far the air stays attached.

Aerohead has put quite a bit of information on site about this very issue. It may be worth a second review before proceeding.

Jim.

|

|

|

|

10-22-2009, 06:04 AM

10-22-2009, 06:04 AM

|

#248 (permalink)

|

|

Master EcoModder

Join Date: May 2008

Location: Maynard, MA Eaarth

Posts: 7,908

Thanks: 3,475

Thanked 2,953 Times in 1,846 Posts

|

Hi,

The top and the bottom of my sketch are arcs, so the angle of change is constant. If the total angle has to be 15 degrees or less on the top, and 4 degrees or less on the bottom -- the thing would be nearly as long the xA itself. This one stick out ~4'-5" from the rear bumper, and the full boattail would be ~11'-0"!

I think in that case, that a full Kamm back (on top, sides and bottom) would be the only practical solution.

Yes, I already have small partial Kamm panels, and I think they do help. |

|

|

|

10-22-2009, 10:27 AM

10-22-2009, 10:27 AM

|

#249 (permalink)

|

|

Master EcoModder

Join Date: Oct 2008

Location: Mid-Atlantic

Posts: 491

Thanks: 170

Thanked 69 Times in 44 Posts

|

Neil, I'm a little late on this one, but I have a bit of experience on the coroplast skirts. Coroplast worked quite well on my Echo when I had it. You can stiffen the bottom edge nicely by driving a steel rod down through the bottom row of the corregation. Take a sample of coroplast to Home Depot or Lowes and find a rod diameter which is just oversize for the corregation tube and drive it into the bottom row of your corroplast skirt. Worked well for me. You can then shape the bottom edge of the skirt a bit.

Quote:

Originally Posted by NeilBlanchard

Hello,

I made some rear wheel skirts this weekend:

I'm not real happy about the acrylic glass -- the stuff is pretty brittle, and where it curves down and under at the front and back -- the tape keeps pulling off. I bought a heat gun to try and soften it up and let it form to the curve, and this may have helped a little...

At first, I tried to use just the acrylic glass, but the air pushed them in and they touched the rims (no matter how much a carved the edge...), so I added the 1/8" x 3/4" aluminum bar, and this seems to have helped.

I think I will do them again (using these as patterns) and use Coroplast (if I can find some). I was hoping the the transparent material would be less noticable, but I think the Coroplast would be a better look -- because we WANT to draw attention to ourselves, right?

Tomorrow, I'll see if they survive the commute to work.

Next on the agenda: foil tape on the alloy wheels to see if they can be made a little more aerodynamic! |

|

|

|

|

10-22-2009, 10:58 AM

10-22-2009, 10:58 AM

|

#250 (permalink)

|

|

Master EcoModder

Join Date: May 2008

Location: Maynard, MA Eaarth

Posts: 7,908

Thanks: 3,475

Thanked 2,953 Times in 1,846 Posts

|

Hi,

Quote:

Originally Posted by jimepting

Neil, I'm a little late on this one, but I have a bit of experience on the coroplast skirts. Coroplast worked quite well on my Echo when I had it. You can stiffen the bottom edge nicely by driving a steel rod down through the bottom row of the corregation. Take a sample of coroplast to Home Depot or Lowes and find a rod diameter which is just oversize for the corregation tube and drive it into the bottom row of your corroplast skirt. Worked well for me. You can then shape the bottom edge of the skirt a bit.

|

Yup, this is exactly what I have now done! This thread is long, so if you skip ahead, you'll see how my Coroplast wheel skirts worked out. Thanks for your comments.

|

|

|

|

|