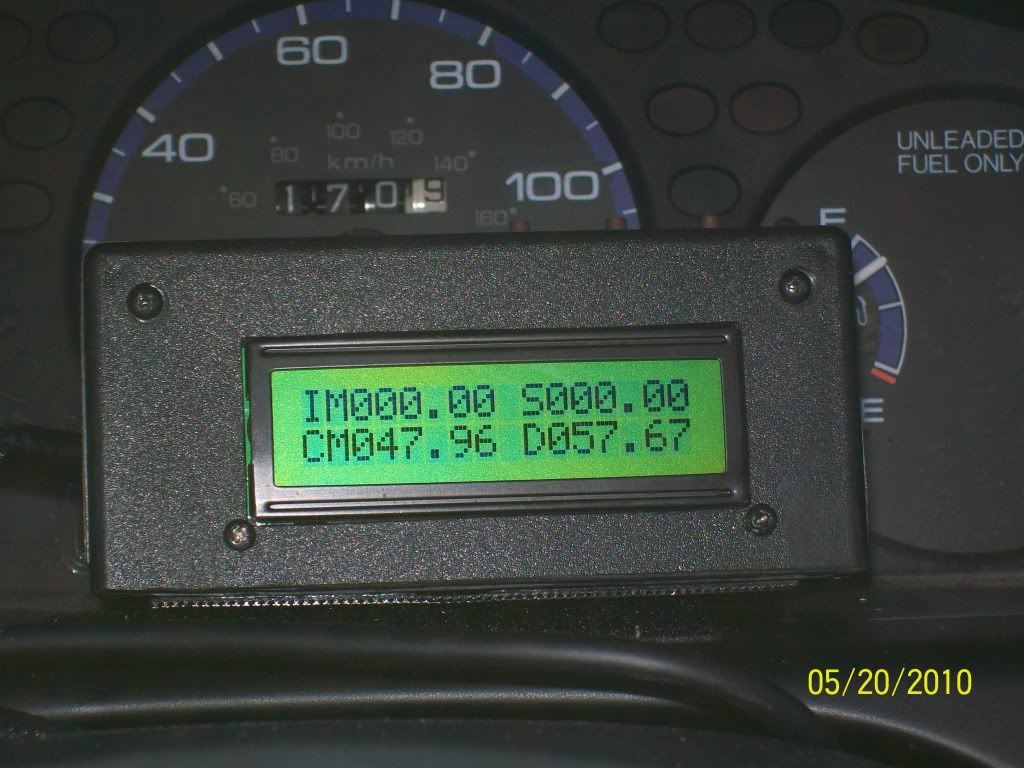

My new case:

47.96 mpg on the 57.67 mi. trip to work this morning.

Previous cardboard case worked great and was compact but not pretty.

New case has rear ventilation slots.

(Later I had to make these MUCH larger, unit would overheat and cut out occasionally. Slots now = approx half the back's surface area.)

New case was made from a much larger case. From an electronic supply place.

Source case had the correct dimension across, about 1/2" bigger than the 4x2x1" Radio Shack case I'd tried earlier (too cramped for this version Guino, imho). I cut down both the height and the depth later.

+

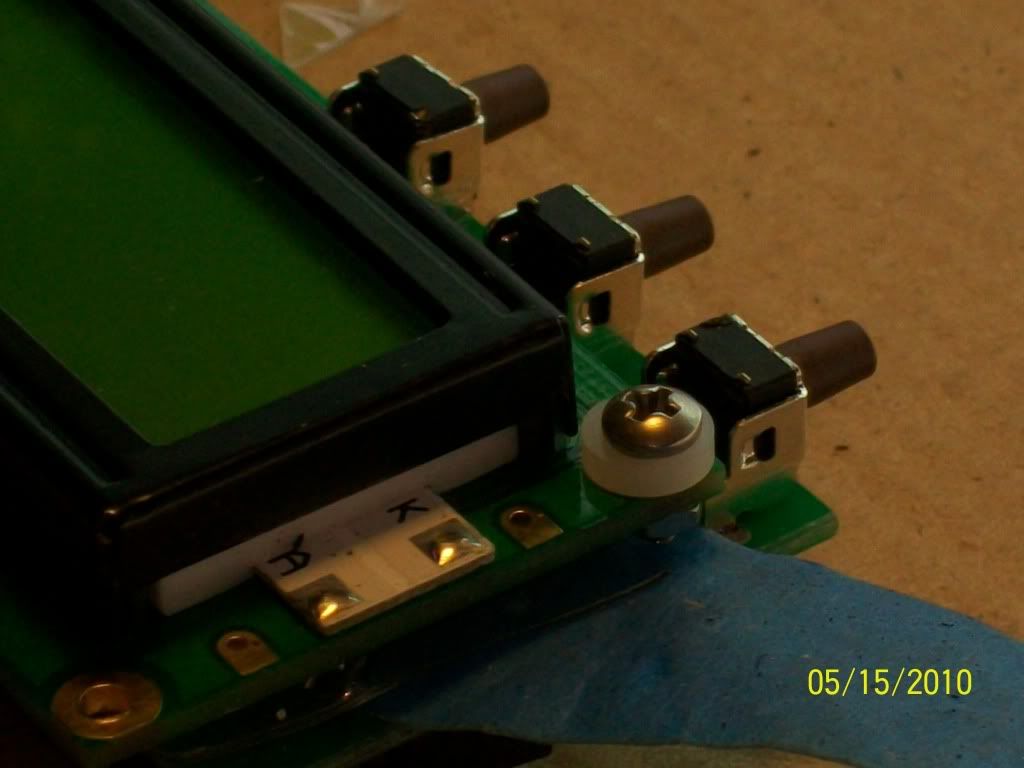

A car pool buddy with more electrical knowledge and experience than I advised me - after my first plastic case um, failed miserably. Advice: There should be no stress on any circuit board. Mount with screws and non-threaded standoffs (bushings) as spacers. Use non conductive materials wherever possible.

I used #3 screws; they fit the holes nicely. #4 is too big. #2 works but they are kinda loose. My screws and nuts are stainless; the washers are #4 nylon.

At the bottom you see 2 screws, each with 2 washers. They anchor the board to the case.

Detail of one of the 2 upper screws. These are spacers that brace (gently) against the back side of the case front panel. You'll need to CAREFULLY trim away some of the sheet plastic that's between the two circuit boards at the corners. Swiss Army knife scissors did it for me. One nylon plus one thin stainless washer built up the right thickness. Note the nylon is against the board, not conductive.

I basically sliced off the entire lower part of the original full case to the short height I wanted. Then it needed a new bottom. Bottom has velcro to stick to dash so I wanted to have a bottom there. Bottom made from the left over front panel that I trimmed off. Note the cuts to mate with the back of case. That's a fiber reinforced cutoff wheel on the "Dremel", which is actually a Black and Decker. It did almost all the cutting I needed for the project.

Here's a shot showing the cut to reduce the depth. I made a new back from more of the front panel trim-off material. JB Quick "weld" epoxy glued on the new bottom and back. Hot glue might melt in summer heat, and regular epoxy is rated only to 200ºF (from the package info). JB Quick is rated to 300ºF so I feel pretty confident in that.

Can't resist showing the trip home from work today.