Last night, I whipped up some more test samples before going to bed.

Earlier in the day, I drizzled generic white school glue onto some foam samples and pushed it around with my popcicle sticks. That made a simple "glue coat" on a piece of pink EPS and on some scrap white styrofoam.

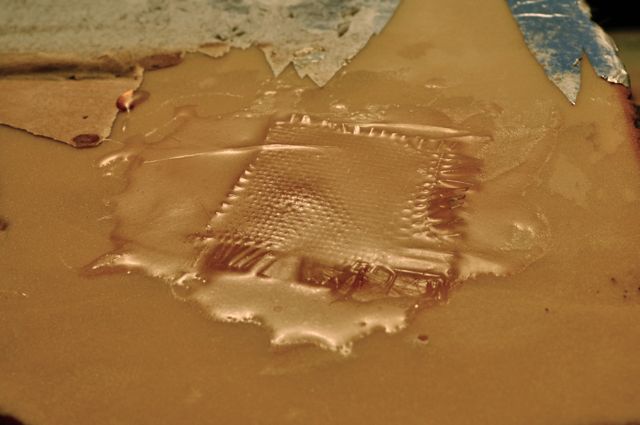

I worked in the evening, but when I got home, the glue was finally dry. I set up a couple of ounces of resin and poured it on both foams and slapped down a sample of fiberglass cloth.

I did the same to some scrap yellow foil-faced foam. (I'm assuming that's polyiso!)

My main concern was curing, as it's now below freezing outside every night, and I was doing this in my uninsulated garage. (There are places where you can see daylight right through the siding!)

I left a 1000 watt work light on all night, pointed right at my samples. That seemed to work well, as everything was completely hardened this morning.

AND all three samples looked pretty good! The resin stayed on top of the glue, and didn't eat the foam at all! The yellow foam looked good too, even without the glue coat.

I had some scrap pipe insulation around (from working on a grill block) and I poured some resin on that. It seemed to react very minimally to the polyester resin. I have no idea what chemistry that foam is, but it doesn't need to be coated before applying fiberglass.

Looks like I now need to price out large sheets of fiberglass and 55 gallon drums of white school glue!

Here's the white styrofoam sample.

And here's the yellow foam sample.

I've started work already on a

flat cover for the truck.