11-26-2012, 02:18 PM

11-26-2012, 02:18 PM

|

#21 (permalink)

|

|

Administrator

Join Date: Dec 2007

Location: Germantown, WI

Posts: 11,203

Thanks: 2,501

Thanked 2,589 Times in 1,555 Posts

|

Woo, looking forward to seeing more tests then. It would be great to have a good low cost alternative for fiberglassing.

...plus I wanna see an aerocap on your truck.

|

|

|

|

Today Today

|

|

|

|

Other popular topics in this forum...

Other popular topics in this forum...

|

|

|

|

11-26-2012, 06:36 PM

11-26-2012, 06:36 PM

|

#22 (permalink)

|

|

Master EcoModder

Join Date: Jan 2008

Location: Sanger,Texas,U.S.A.

Posts: 16,387

Thanks: 24,467

Thanked 7,407 Times in 4,799 Posts

|

foam

Quote:

Originally Posted by bennelson

Thanks for all the responses!

Daox: I was digging through my pile of scrap materials, and there was a small piece of yellow foil board, like what you are in using. I said to myself "Ah ha! I bet that's urethane in there!"

NeilBlanchard: I did some searching on a prop-building forum and saw a demo of using PVA glue (plain white school glue basically...) as a coating over foam for building Iron Man armor. It looked REALLY good.

I'm planning on doing a test with white glue over foam and see how it works.

I DID do a test with aluminum foil, and it worked well for preventing damage to the foam, but as was said, it doesn't bond to the foam at all then. Would work fine for mold-making!

|

*The polyisocyanrurate foam is chemically similar to urethane,so polyester resin is okay with it.

*Any of the 'Styrofoams',as mentioned,can be sealed with Elmer's glue,Elmer's Carpenter's Glue,or Titebond,ahead of using polyester resin.

*Polyurethane Marine Spar Varnish can also be used on Styrofoam to create a block,allowing the use of polyester resin and polyester-based body fillers such as Bondo brand.

*Aluminum foil can be squeegied on over a coating of general-purpose axle grease,directly on a finished automotive finish to create a bleed-proof block and release mechanism for wet-layups applied directly over a vehicle when integrating spoilers,tails,and whatnot.The foil itself can receive multiple carnuba waxings along with a coat of polyvinyl alcohol release agent prior to laying up to release the foil from the part after the cure.

After the 'part' is completed,you slip it off the car,peel the foil away,then GUNK the area to remove the grease.

__________________

Photobucket album: http://s1271.photobucket.com/albums/jj622/aerohead2/

|

|

|

|

|

The Following 3 Users Say Thank You to aerohead For This Useful Post:

|

|

11-27-2012, 02:18 AM

11-27-2012, 02:18 AM

|

#23 (permalink)

|

|

Master EcoModder

Join Date: Oct 2012

Location: Carson City, Nevada

Posts: 612

Thanks: 240

Thanked 114 Times in 90 Posts

|

Wow, good tips, aerohead!! I would have never thought of "glueing" aluminum foil to the car body with grease!!!! But I can see how it would work perfectly!!! Brilliant!!!!  |

|

|

|

11-27-2012, 10:13 AM

11-27-2012, 10:13 AM

|

#24 (permalink)

|

|

EV test pilot

Join Date: Jan 2008

Location: Oconomowoc, WI, USA

Posts: 4,435

Thanks: 17

Thanked 663 Times in 388 Posts

|

Last night, I whipped up some more test samples before going to bed.

Earlier in the day, I drizzled generic white school glue onto some foam samples and pushed it around with my popcicle sticks. That made a simple "glue coat" on a piece of pink EPS and on some scrap white styrofoam.

I worked in the evening, but when I got home, the glue was finally dry. I set up a couple of ounces of resin and poured it on both foams and slapped down a sample of fiberglass cloth.

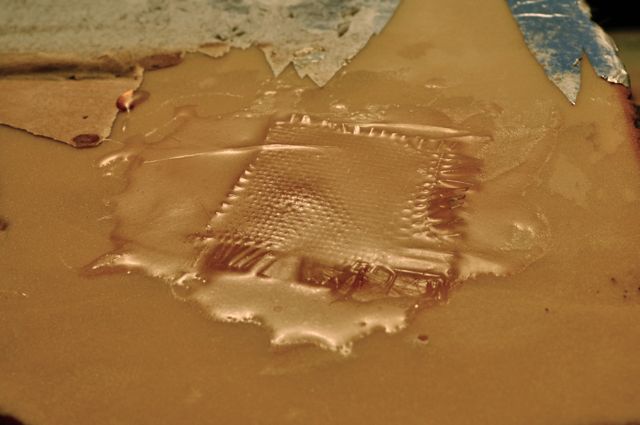

I did the same to some scrap yellow foil-faced foam. (I'm assuming that's polyiso!)

My main concern was curing, as it's now below freezing outside every night, and I was doing this in my uninsulated garage. (There are places where you can see daylight right through the siding!)

I left a 1000 watt work light on all night, pointed right at my samples. That seemed to work well, as everything was completely hardened this morning.

AND all three samples looked pretty good! The resin stayed on top of the glue, and didn't eat the foam at all! The yellow foam looked good too, even without the glue coat.

I had some scrap pipe insulation around (from working on a grill block) and I poured some resin on that. It seemed to react very minimally to the polyester resin. I have no idea what chemistry that foam is, but it doesn't need to be coated before applying fiberglass.

Looks like I now need to price out large sheets of fiberglass and 55 gallon drums of white school glue!

Here's the white styrofoam sample.

And here's the yellow foam sample.

I've started work already on a flat cover for the truck. |

|

|

|

|

The Following 2 Users Say Thank You to bennelson For This Useful Post:

|

|

11-27-2012, 10:16 AM

11-27-2012, 10:16 AM

|

#25 (permalink)

|

|

Administrator

Join Date: Dec 2007

Location: Germantown, WI

Posts: 11,203

Thanks: 2,501

Thanked 2,589 Times in 1,555 Posts

|

Woo, glad to hear you got it to work out. Now you have a few options!

You don't need large sheets of fiberglass. You can just patchwork them together. A tip I got when doing this is to tear your fiberglass apart, do not cut it. It makes everything blend together better. You'll need to sand everything down eventually, at that point you can work out the higher points.

|

|

|

|

11-27-2012, 10:40 AM

11-27-2012, 10:40 AM

|

#26 (permalink)

|

|

Master EcoModder

Join Date: May 2008

Location: Maynard, MA Eaarth

Posts: 7,908

Thanks: 3,475

Thanked 2,952 Times in 1,845 Posts

|

White glue is not waterproof - it will dissolve in water even after hardening. Ya' gotta use "exterior" waterproof glue, which is yellow or light brown - but not all yellow glues are waterproof.

|

|

|

|

11-27-2012, 11:09 AM

11-27-2012, 11:09 AM

|

#27 (permalink)

|

|

EV test pilot

Join Date: Jan 2008

Location: Oconomowoc, WI, USA

Posts: 4,435

Thanks: 17

Thanked 663 Times in 388 Posts

|

Does water-proofness of glue matter? Once it's covered with set fiberglass it should be weatherproof, right?

Could non-waterproof glue somehow react poorly UNDER the set fiberglass?

I was just using what I had handy. Maybe I'll put my sample in the bath-tub and scrub with hot water and see what happens.

Anyone have a recommendation for a fiberglass materials supplier? Is this the sort of thing that's good to do by mail-order, or should I try to find someplace local?

|

|

|

|

11-27-2012, 12:21 PM

11-27-2012, 12:21 PM

|

#28 (permalink)

|

|

Master EcoModder

Join Date: May 2008

Location: Maynard, MA Eaarth

Posts: 7,908

Thanks: 3,475

Thanked 2,952 Times in 1,845 Posts

|

Structural fiberglass often will eventually crack.

|

|

|

|

11-27-2012, 04:02 PM

11-27-2012, 04:02 PM

|

#29 (permalink)

|

|

Aero Deshi

Join Date: Jan 2010

Location: Vero Beach, FL

Posts: 1,065

Thanks: 430

Thanked 669 Times in 358 Posts

|

Saw ACK! and I couldn't contain myself

|

|

|

|

11-28-2012, 01:26 PM

11-28-2012, 01:26 PM

|

#30 (permalink)

|

|

EV test pilot

Join Date: Jan 2008

Location: Oconomowoc, WI, USA

Posts: 4,435

Thanks: 17

Thanked 663 Times in 388 Posts

|

Yes, that cartoon is an appropriate visualization about how I feel when I'm trying to do something I know NOTHING about!

I did do some work sanding the white sytrofoam (Ick! Snowglobe of Evil!)

And glued the two halves of my cover together with Great Stuff. I even ran an extra but down the edges of the cover to get more of a nice curved fit. I did that over aluminum foil and cooking spray, and didn't get ANY Great Stuff stuck all over!

Now, I'm trying to figure out how the whole thing will be held down to the truck. What are typical methods used on foam/fiberglass composites? I'm assuming that a bolt or some other fastener needs to be embedded in the fiberglass. I would think the weight or force needs to be spread out a bit too.

Do I need to do something like run a bolt through a piece of fiberglass, and into the foam, and fiberglass over the whole thing?

Ideally, I'd like the lid hinged, to make it easier to load the bed, but for a really simple clamping system, I noticed that the bottom of the foam is about level with the bottom of the frame rails. It would be pretty easy to just put a metal plate across the bottom of the two and a bolt up into the foam. It could be tightened with a nut or wing-nut.

Here's a terrible, not-to-scale drawing to help illustrate.

Could I do a Tee-nut fiberglassed into the foam so that I could easily remove external hardware?

Other ideas?

|

|

|

|

|