Quote:

Originally Posted by RedDevil

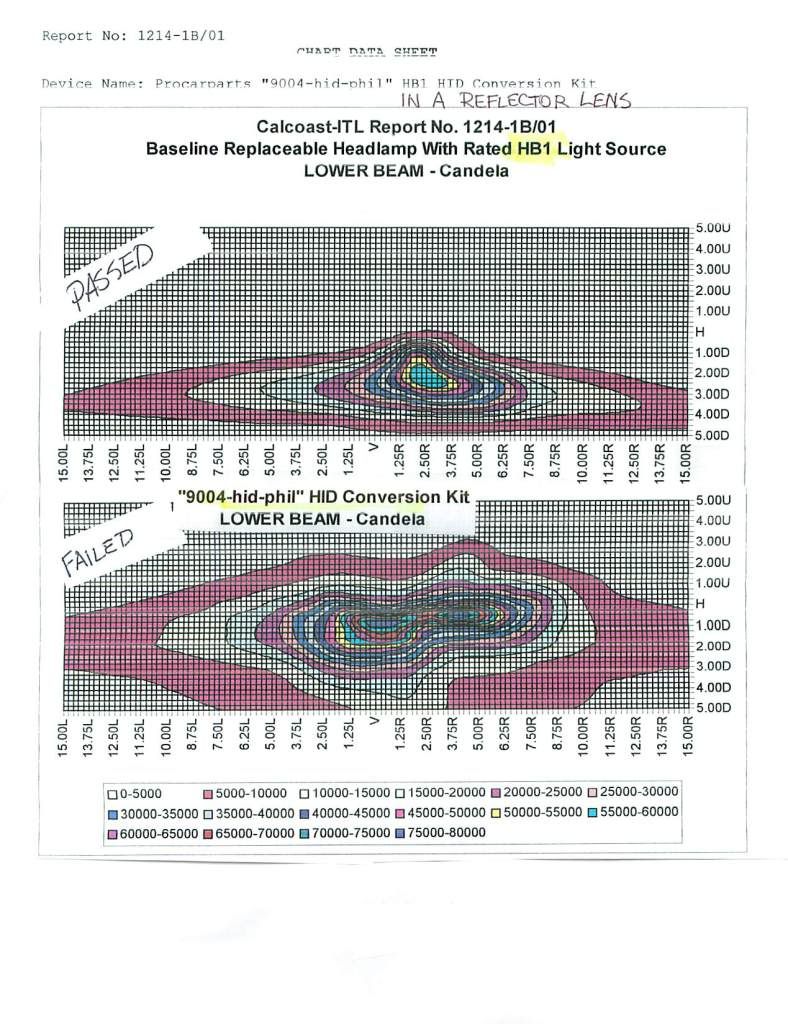

OK, so let us look at those facts, from post 1.

This is a joke, right?

The alignment is out. You can clearly see that the point of highest intensity is aimed way too high in the second picture. It should have been aligned, but it wasn't.

Nothing good can come from testing like this.

Did the government do this? They should be ashamed. |

************************************************

edit: here is what you are missing or don't seem to understand.

1. the test is a low beam test.

2. the correct halogen bulb probably has a cover on the tip.

3. ALL hid bulbs require a metal shield to provide a cutoff

4. the hid bulb that was installed is being sold as a direct replacement of the low beam halogen.

5. NOTHING is being un-aligned by the tester.

****************************************

Tell you what, you call CALCOAST-ITL and talk to them.

Gosh, I did and am smarter for it.

THe top picture(passed) is the halogen bulb in the halogen lamp.

The second picture is the HID kit installed in the halogen lamp. INSTALLED AS ANY CONSUMER WOULD INSTALL IT. THe base of the bulb in the proper spot. NOT JURY RIGGERD!!!!

It's a government approved testing procedure.....you know, like the procedures that put a man on the moon....

It is the same standard test that ALL MANUFACTURERS HAVE to go thru.

SO by your standard, each manufacturer gets to come and jiggle their bulbs.....

Maybe you just don't get it..... I don't know. But the only 'aligning' is of the lamp, using the alignment bolts provided by the manufacturer on the car.

Finally, when you look at an HID bulb there are two FACTS:

1. there are two hotspots

2. there is an arch

Tell me, how do you compensate, or align for those two FACTS when a halogen is a straight single hotspot?