Ok. Long break. All the parts came in, here's what you missed.

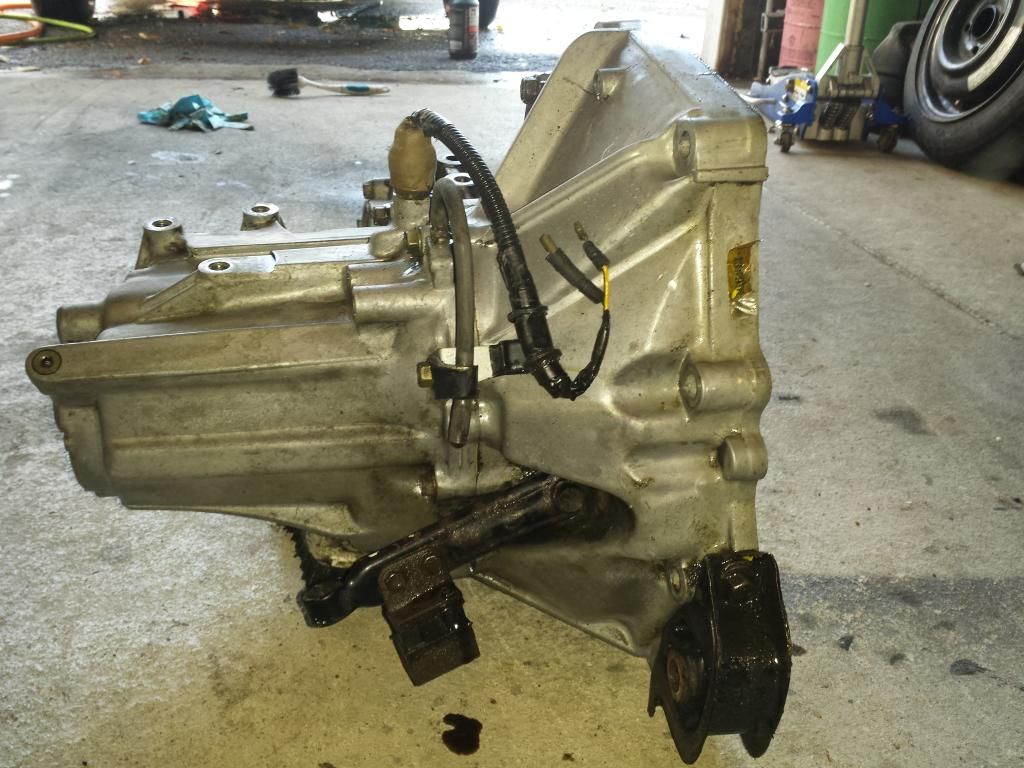

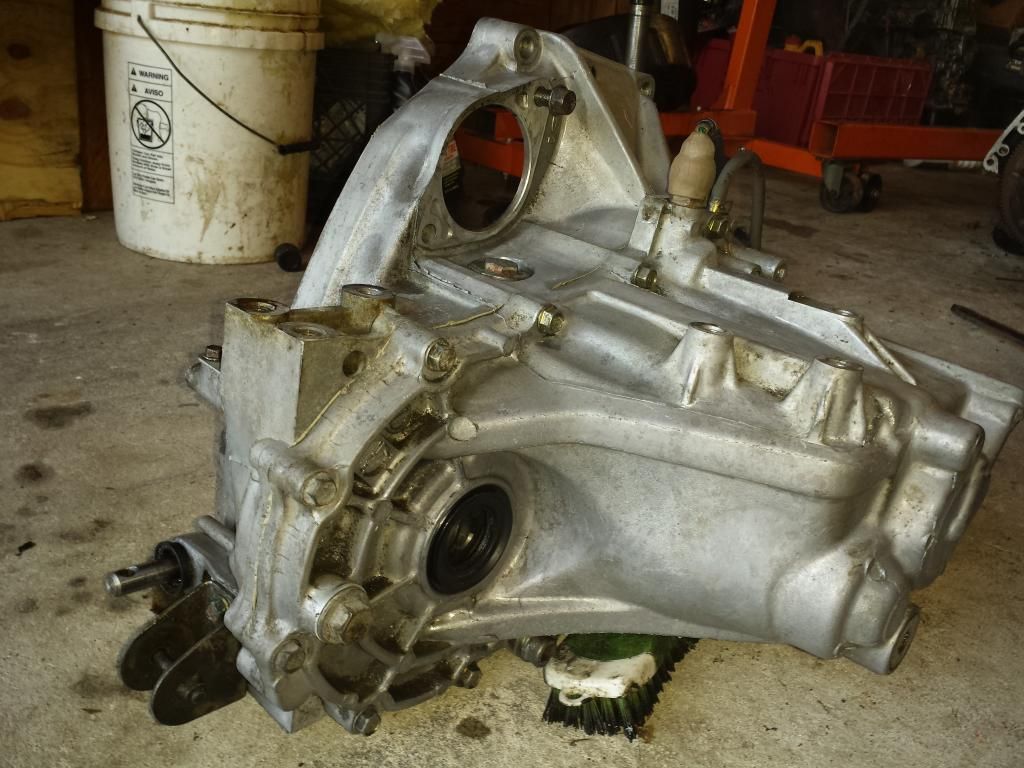

My buddy came over and helped me pull the motor once I got my hoist. I separated the motor and tranny. rebuilt the tranny, and glad I did. The differential bearings were pretty crunchy

(didn't bother taking pictures of the guts, it looks just like a vx tranny inside with the big aluminum shift forks, and I have pictures of the last two vx's guts) and different mounts outside. I only cleaned it up enough to get the case open without getting crap inside

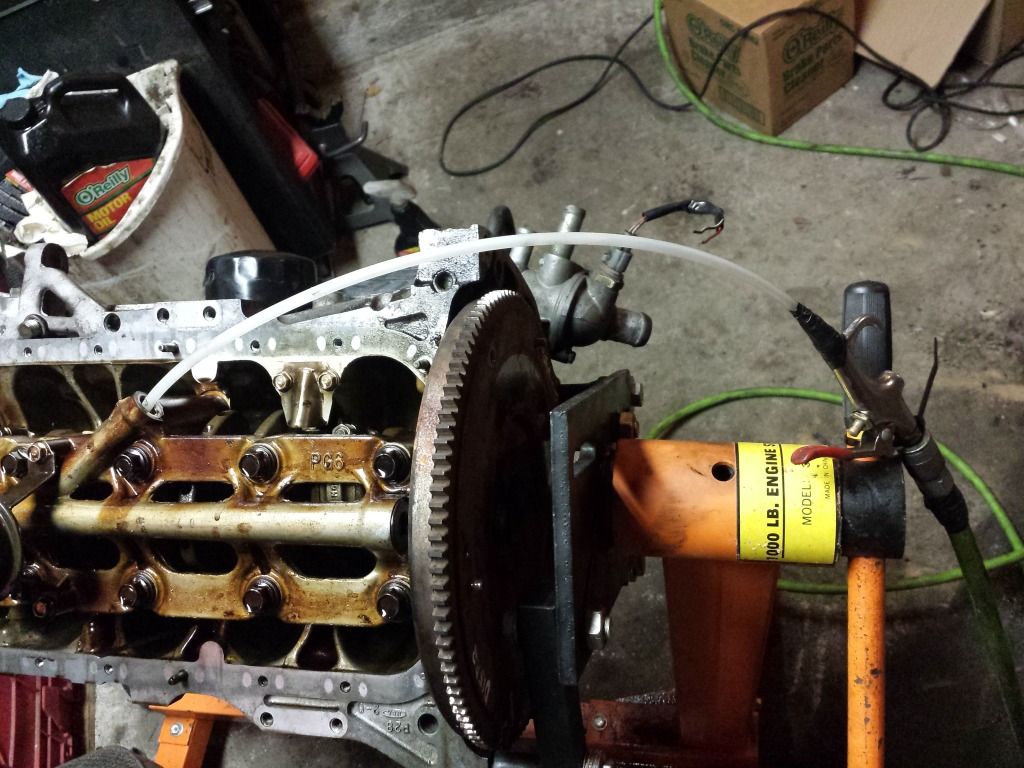

then I had to tackle the oil jet. Here's how that went.

I opened the oil passage with an 8mm hex

then I rigged up my air line with a 1/4 inch plastic tubing and zip tied the handle to the engine stand, then zip tied the nozzle on full blast:

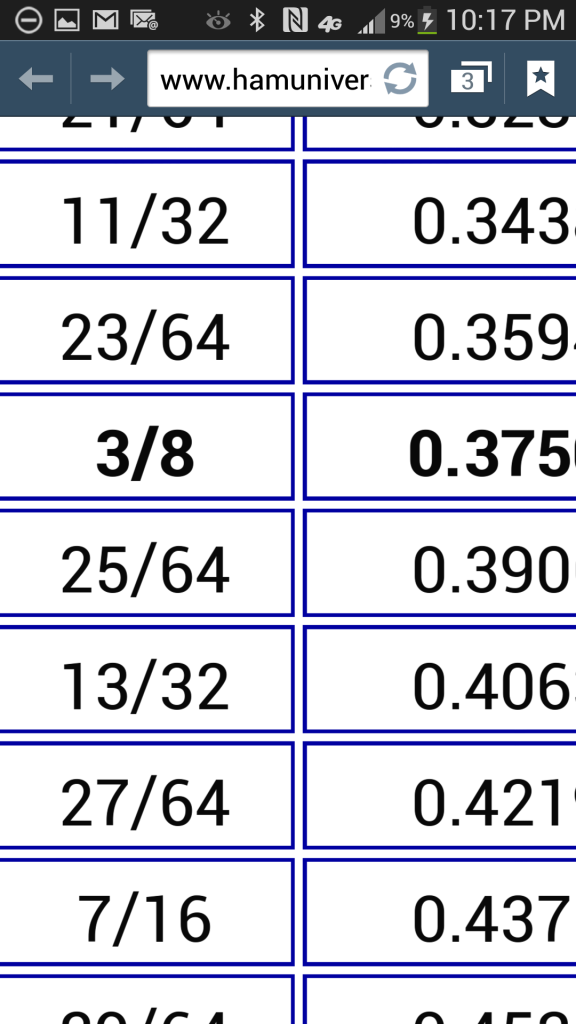

Measured the new block opening sorry it's upside down

Measured the oil jet

Did some "math"

Got a drill bit (only used the 25/64 bit)

Turned the air on, held my breath, and drilled the hole out, and voilą! OIL JET!!!

Big hurdle crossed, I put the motor together

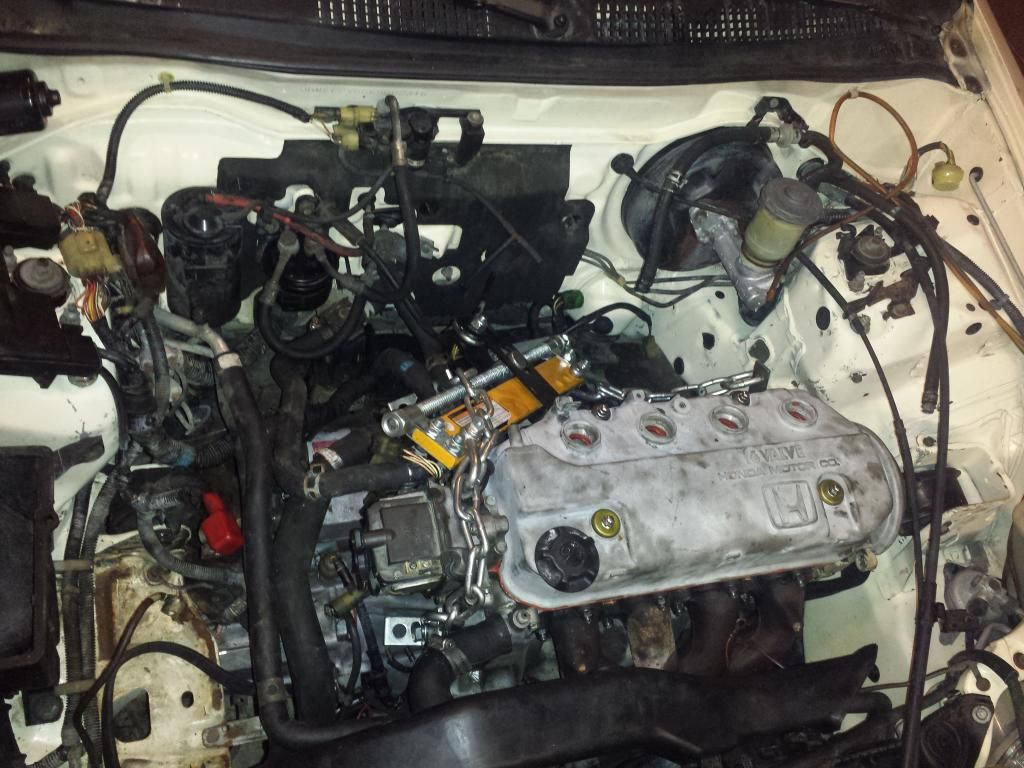

Since I will be re-using the 1989 tranny, it's important to note that I put the 1989 flywheel, clutch, and pressure plate on the motor as well to avoid possible issues with spline counts, flywheel bearing, etc. .. married the motor and tranny and dropped the whole package into the engine bay

and haven't had time to play since

but the old lady got me a deal and a half on 4 new tires at farm and fleet and since Skiddy is on jackstands, I jumped! - $275 Mount, balance, and road hazard 40k tires. They need more air!

And that's as far as I've come now. Motor needs oil, tranny needs synchromesh, cv axles need to go back in, intake manifold, wiring, plumbing, etc. Etc.

Hope all my pictures don't "break the interweb"

Quick and dirty sure is slow around here, isn't it?

Thanks,

Victor