The International Harvester 300 Utility has a 40 HP engine and 11 gallon gas tank.

It has live hydraulics and independent PTO. The hydraulics continue to work whether or not the clutch is pushed in. The PTO is turned on and off with a lever to the right of the operators seat.

The Nissan Leaf EM57 motor is rated at 107 HP, but that's at a higher speed.

At 2,000 RPM, which is what tractors typically run at, it's about 70 HP, far more than the gas engine 40 HP.

Similar time period Farmall brand tractors used the same transmission, but the engine was NOT part of the frame. Instead, rails extended from the transmission bell housing to the tractor's front axle. I bought a pair of rails from a Farmall H tractor and will bolt them to the tractor.

Today, I cut down the frame rails to the same length as the engine, pulled the front end to about where it should go, and connected the yoke from the front axle to the tranny.

This gives me the original length of the tractor, and now lets me figure out the spacing and placement of the required EV components.

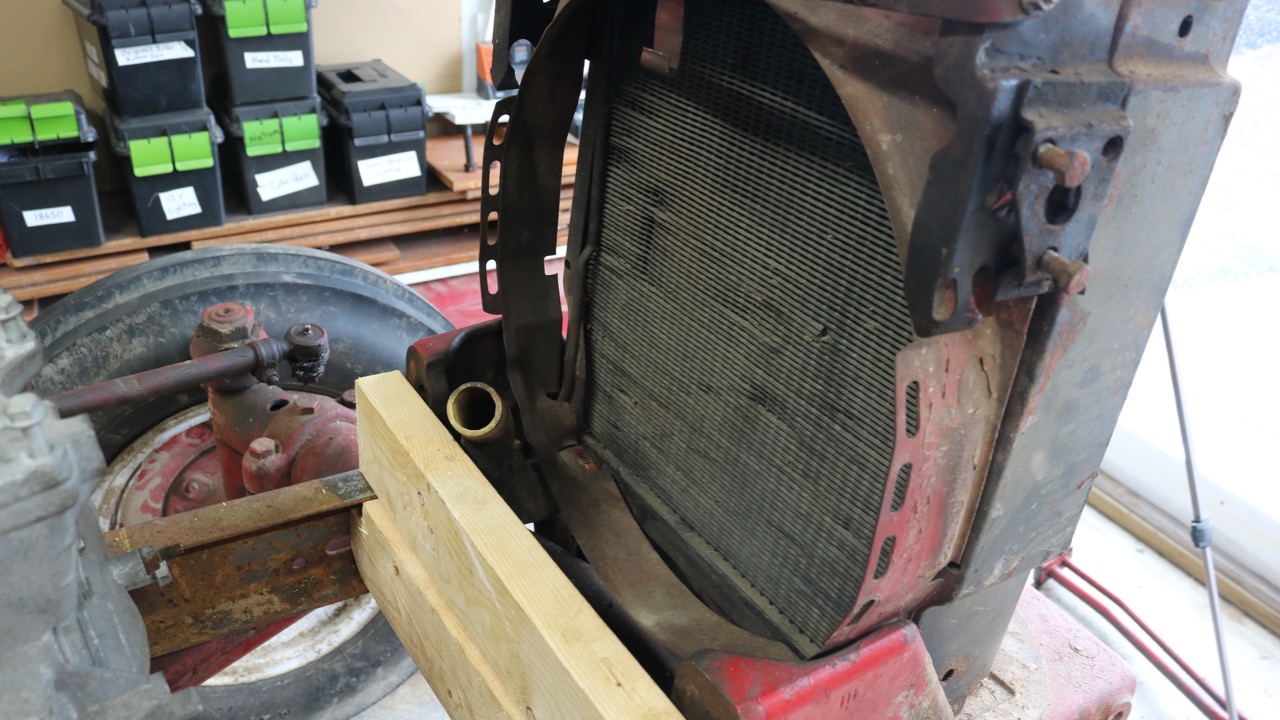

Radiator back in place.

The electric motor is sitting a little high right now, as this is just a mock-up and it's just sitting on a board across the bottom of the frame rails. The motor should sit about 4 inches lower than it is right now.