03-26-2020, 05:15 PM

03-26-2020, 05:15 PM

|

#21 (permalink)

|

|

Human Environmentalist

Join Date: Aug 2010

Location: Oregon

Posts: 13,012

Thanks: 4,374

Thanked 4,549 Times in 3,496 Posts

|

I have an electric push-mower and will never go back.

I actually think I'd try an electric riding mower if I had a yard just the right size for one.

|

|

|

|

Today Today

|

|

|

|

Other popular topics in this forum...

Other popular topics in this forum...

|

|

|

|

03-26-2020, 06:44 PM

03-26-2020, 06:44 PM

|

#22 (permalink)

|

|

It's all about Diesel

Join Date: Oct 2012

Location: Porto Alegre, Rio Grande do Sul, Brazil

Posts: 13,032

Thanks: 0

Thanked 1,720 Times in 1,534 Posts

|

Quote:

Originally Posted by oil pan 4

My Kubota that was first sold in 1978 is space age compared to those things. The hydraulics are driven straight off the engine, so when you push in the clutch all the hydraulics keep going.

|

Makes me remember some older trucks with a front-mounted PTO which I used to see before cabovers became so prevalent in my country even at construction sites. I always disliked transmission-mounted PTOs, since they seem to have higher losses due to the internal frictions on the transmission too. |

|

|

|

03-26-2020, 09:24 PM

03-26-2020, 09:24 PM

|

#23 (permalink)

|

|

Master EcoModder

Join Date: Feb 2014

Location: Missoula, MT

Posts: 2,668

Thanks: 305

Thanked 1,187 Times in 813 Posts

|

The first thing that came to my mind was the engine IS the tractor. I see you are covering that. What makes a tractor a tractor is the engine is the frame. The name came from 'traction engine', so it's an engine that can move. Then attach stuff to said engine and do tasks. So this is a "traction motor" which is actually shortens better to tractor. The old diesel ones should be tracgens maybe.

|

|

|

|

03-26-2020, 09:26 PM

03-26-2020, 09:26 PM

|

#24 (permalink)

|

|

Master EcoModder

Join Date: Feb 2014

Location: Missoula, MT

Posts: 2,668

Thanks: 305

Thanked 1,187 Times in 813 Posts

|

Quote:

Originally Posted by redpoint5

I have an electric push-mower and will never go back.

I actually think I'd try an electric riding mower if I had a yard just the right size for one.

|

Look at this bad boy

https://www.husqvarna.com/us/product...automower-awd/ |

|

|

|

03-26-2020, 09:37 PM

03-26-2020, 09:37 PM

|

#25 (permalink)

|

|

Human Environmentalist

Join Date: Aug 2010

Location: Oregon

Posts: 13,012

Thanks: 4,374

Thanked 4,549 Times in 3,496 Posts

|

A robot mower has been on my mind for a while. All of my yards would be right-sized for one, but they sure are expensive. They would really have to be problem-free for me to drop that kind of money. At those prices, I better only have to set it up in the spring, and service/store it in the fall.

I was thinking along these lines for a larger yard:

|

|

|

|

03-27-2020, 05:30 PM

03-27-2020, 05:30 PM

|

#26 (permalink)

|

|

It's all about Diesel

Join Date: Oct 2012

Location: Porto Alegre, Rio Grande do Sul, Brazil

Posts: 13,032

Thanks: 0

Thanked 1,720 Times in 1,534 Posts

|

Quote:

Originally Posted by redpoint5

A robot mower has been on my mind for a while.

|

I'd rather leave the grass to feed some livestock  |

|

|

|

03-27-2020, 05:42 PM

03-27-2020, 05:42 PM

|

#27 (permalink)

|

|

Human Environmentalist

Join Date: Aug 2010

Location: Oregon

Posts: 13,012

Thanks: 4,374

Thanked 4,549 Times in 3,496 Posts

|

Quote:

Originally Posted by cRiPpLe_rOoStEr

I'd rather leave the grass to feed some livestock  |

My lawn could maybe support 1 small goat.

Parents sold off the sheep herd 20 years ago. |

|

|

|

03-28-2020, 10:42 PM

03-28-2020, 10:42 PM

|

#28 (permalink)

|

|

Master EcoModder

Join Date: Sep 2010

Location: Saskatoon, canada

Posts: 1,488

Thanks: 746

Thanked 565 Times in 447 Posts

|

Quote:

Originally Posted by redpoint5

A robot mower has been on my mind for a while. All of my yards would be right-sized for one, but they sure are expensive. They would really have to be problem-free for me to drop that kind of money. At those prices, I better only have to set it up in the spring, and service/store it in the fall.

|

A robot mower has ALSO been on my mind for a while (like maybe 20 years)

It is now possible to implement without burying a cable around your entire yard.

But I have a dilemma ... and I don't like EITHER choice

- a one-of prototype costs too much. AND it takes a lot of time.

- an off-the-shelf unit costs a bit less, but you need to pay someone to fix it since they are all very secretive about how their equipment works.

So ... I'd like to go halfway ... start with an older robomow or similar, do a bit of reverse engineering to figure out what pins need to be driven to get it moving and mowing, then add the guidance system and mapping with a PI 4 and some add-on modules. It's one of my retirement projects ...

__________________

In THEORY there is no difference between Theory and Practice

In PRACTICE there IS!

|

|

|

|

03-29-2020, 01:05 PM

03-29-2020, 01:05 PM

|

#29 (permalink)

|

|

EV test pilot

Join Date: Jan 2008

Location: Oconomowoc, WI, USA

Posts: 4,435

Thanks: 17

Thanked 663 Times in 388 Posts

|

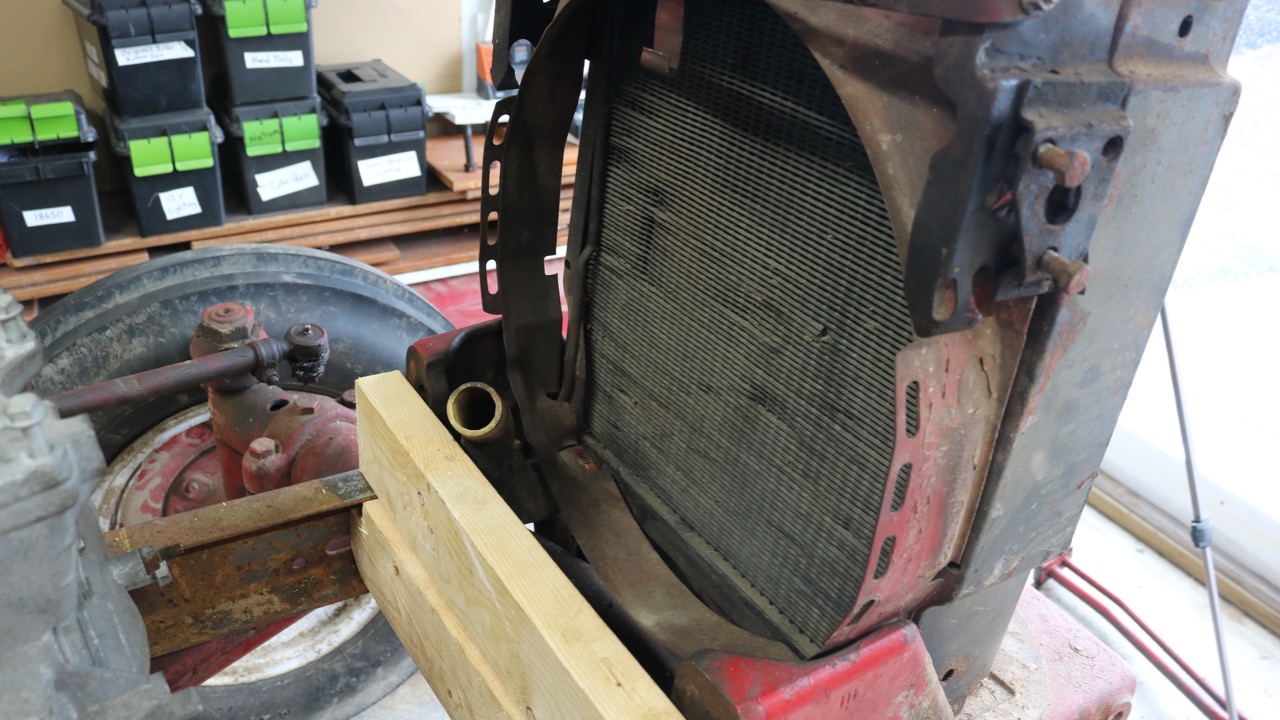

The International Harvester 300 Utility has a 40 HP engine and 11 gallon gas tank.

It has live hydraulics and independent PTO. The hydraulics continue to work whether or not the clutch is pushed in. The PTO is turned on and off with a lever to the right of the operators seat.

The Nissan Leaf EM57 motor is rated at 107 HP, but that's at a higher speed.

At 2,000 RPM, which is what tractors typically run at, it's about 70 HP, far more than the gas engine 40 HP.

Similar time period Farmall brand tractors used the same transmission, but the engine was NOT part of the frame. Instead, rails extended from the transmission bell housing to the tractor's front axle. I bought a pair of rails from a Farmall H tractor and will bolt them to the tractor.

Today, I cut down the frame rails to the same length as the engine, pulled the front end to about where it should go, and connected the yoke from the front axle to the tranny.

This gives me the original length of the tractor, and now lets me figure out the spacing and placement of the required EV components.

Radiator back in place.

The electric motor is sitting a little high right now, as this is just a mock-up and it's just sitting on a board across the bottom of the frame rails. The motor should sit about 4 inches lower than it is right now. |

|

|

|

|

The Following User Says Thank You to bennelson For This Useful Post:

|

|

03-29-2020, 05:52 PM

03-29-2020, 05:52 PM

|

#30 (permalink)

|

|

EcoModding Apprentice

Join Date: Mar 2009

Location: Costa Rica

Posts: 138

Thanks: 24

Thanked 47 Times in 39 Posts

|

Nice conversion project. I am curious how you plan to adapt the motor shaft to the tranny shaft. It is a non-standard spline arrangement. I tried to get sufficient interest in ordering a broach to make the coupler, but, not enough interest for me to follow through.

|

|

|

|

|