05-09-2020, 01:58 PM

05-09-2020, 01:58 PM

|

#11 (permalink)

|

|

Master EcoModder

Join Date: Jun 2016

Location: KY

Posts: 1,352

Thanks: 63

Thanked 366 Times in 269 Posts

|

Just read through this thread, and I’m feeling inspired now lol. Given that I have rain guards it complicates the solution for my particular situation. The title led me to believe that you were extending a fence forward of the pillar, similar to the flying buttresses on the back of certain cars

__________________

My current Ecotec project...

My last Ecotec project...

|

|

|

|

Today Today

|

|

|

|

Other popular topics in this forum...

Other popular topics in this forum...

|

|

|

|

05-09-2020, 06:57 PM

05-09-2020, 06:57 PM

|

#12 (permalink)

|

|

Master EcoModder

Join Date: Aug 2012

Location: northwest of normal

Posts: 29,410

Thanks: 8,365

Thanked 9,125 Times in 7,534 Posts

|

It's hard to keep up with everything happening in the World and you, OP. I was headed to the last thread to talk about water tunnels and ask about aluminum extrusions for vertical axis windmill airfoils.

So here it is. You speculate that the unlikely separation is due to the angle on the hood. Could it be that to optimize the air/water substitution, the overall fineness ratio might need to be 2 or 3X in the forward direction?

For prior art it's easier to point to the original source than a Pemalink within Ecododder.

Reducing Windnoise / Raingutter Fillers – Gerrelt's Garage

The airfoil has some built-in advantage as a cross-section. The scale might be no greater than the acoustic silencers.

Quote:

|

(It came with a small vertical axis wind turbine I bought.)

|

I'm getting some new neighbors and I hope to rope them into helping put a windmill on an unused utility pole between us. I have a 25ft 1"hex bar for a vertical shaft and I would like a Savonius/Darrieus hybrid rotor at the top sized for a 1hp Fisher-Paykel washing machine motor (in hand) at the bottom for easy maintenance.

I'd though of 3-4" timber bamboo split into thirds and shaved into an airfoil green, then strapped into a spiral form to be carbonized. Thoughts?

edit: On the supposition that a vertical pole has a vibrational node at 2/3rd it's height, that's where I'd put a captive wheelbarrow wheel and tire as a vibration damper. Maybe you could suggest a tuned mass damper on the shaft below the bearing? The shaft is to store energy in torsion to overcome stiction.

__________________

.

.Without freedom of speech we wouldn't know who all the idiots are. -- anonymous poster

___________________

.

.tragectory: Line goes down and to the right.

Last edited by freebeard; 05-09-2020 at 07:07 PM..

|

|

|

|

05-09-2020, 07:26 PM

05-09-2020, 07:26 PM

|

#13 (permalink)

|

|

Banned

Join Date: Nov 2017

Location: Australia

Posts: 2,060

Thanks: 107

Thanked 1,608 Times in 1,137 Posts

|

Quote:

Originally Posted by freebeard

It's hard to keep up with everything happening in the World and you, OP. I was headed to the last thread to talk about water tunnels and ask about aluminum extrusions for vertical axis windmill airfoils.

So here it is. You speculate that the unlikely separation is due to the angle on the hood. Could it be that to optimize the air/water substitution, the overall fineness ratio might need to be 2 or 3X in the forward direction?

For prior art it's easier to point to the original source than a Pemalink within Ecododder.

Reducing Windnoise / Raingutter Fillers – Gerrelt's Garage

The airfoil has some built-in advantage as a cross-section. The scale might be no greater than the acoustic silencers.

I'm getting some new neighbors and I hope to rope them into helping put a windmill on an unused utility pole between us. I have a 25ft 1"hex bar for a vertical shaft and I would like a Savonius/Darrieus hybrid rotor at the top sized for a 1hp Fisher-Paykel washing machine motor (in hand) at the bottom for easy maintenance.

I'd though of 3-4" timber bamboo split into thirds and shaved into an airfoil green, then strapped into a spiral form to be carbonized. Thoughts?

edit: On the supposition that a vertical pole has a vibrational node at 2/3rd it's height, that's where I'd put a captive wheelbarrow wheel and tire as a vibration damper. Maybe you could suggest a tuned mass damper on the shaft below the bearing? The shaft is to store energy in torsion to overcome stiction. |

Yes, Gerrelt's A pillar modification is the one I cover in my book. Nice guy.

Re the Savonius/Darrieus hybrid wind turbine, I love VAWTs but in the real world, their efficiency always seems lower than a conventional HAWT. If I were building a wind turbine, I'd be using a truck fan as the driver. Not sure how the F&P motor will work at those speeds though. (I used to collect F&P motors - used to be lots in local tips - but I never used them so I finally threw them away!)

Re vibration dampers (and the wheelbarrow wheel sounds ingenious), it's a bit like aerodynamics. I prefer to experiment rather than theorise. (And if doing so, don't forget the ability of smart phone (equipped with a suitable app) to directly record, log and analyse vibration data. The use of a phone is a radical gamechanger in this area.)

(And re the GOE222 VAWT aluminum extrusion. I am enormously impressed with this. It really seems to do what it is supposed to. I 've had a good look around the web and it's the only one I can find like it, ie has a 'proper and official' aerofoil shape with specs available.) |

|

|

|

|

The Following User Says Thank You to JulianEdgar For This Useful Post:

|

|

05-09-2020, 07:51 PM

05-09-2020, 07:51 PM

|

#14 (permalink)

|

|

Banned

Join Date: Nov 2017

Location: Australia

Posts: 2,060

Thanks: 107

Thanked 1,608 Times in 1,137 Posts

|

Final results with and without aerofoil turning vane and one vortex generator.

Without:

With:

However, I am not completely happy. I want one long extrusion from top to bottom of the pillar, so that the end plates aren't placed in front of the area of interest. (I could of course cut the ends of the aerofoil section so that they're more horizontal, but then the turning vane gets even shorter.)

Incidentally, I spent some time tuning the inlet/outlet area (and of course the vane angle changes at same time) and got best results when inlet width was 17mm and outlet 8mm. |

|

|

|

|

The Following 3 Users Say Thank You to JulianEdgar For This Useful Post:

|

|

05-09-2020, 08:32 PM

05-09-2020, 08:32 PM

|

#15 (permalink)

|

|

Master EcoModder

Join Date: Aug 2012

Location: northwest of normal

Posts: 29,410

Thanks: 8,365

Thanked 9,125 Times in 7,534 Posts

|

Quote:

|

Re vibration dampers... I prefer to experiment rather than theorise.

|

Theory before intention, intention before part in hand.  My intuition is that the proper location for the damper would be 2/5th of the 2/3rd height. As a starting point.

The hybrid turbine comes from www.youtube.com/channel/UC6uqmgwTszEq52WaoNvA_1w/videos

Savonius to start up and then the Darrieus rotor takes off.

For the A-pillar turning vane, maybe there's some thing to be learnt from automotobuzz.com: What F1’s 2020 wing designs tell us about each team – Part IV

I think end plates and capes are the same thing? The half-tubes on the bottom of the endplates appear to be squirting air at the tire/pavement interface.

A 3d printed part could be any NACA airfoil, with washout and chord profiling.

__________________

.

.Without freedom of speech we wouldn't know who all the idiots are. -- anonymous poster

___________________

.

.tragectory: Line goes down and to the right.

|

|

|

|

12-01-2020, 01:29 PM

12-01-2020, 01:29 PM

|

#16 (permalink)

|

|

Master EcoModder

Join Date: Jan 2012

Location: United States

Posts: 1,756

Thanks: 104

Thanked 407 Times in 312 Posts

|

Does this have any effect on noise? What about the vortex generators?

I'm asking since I am going to be driving a lot of highway miles and the Infiniti G35 I bought has a ton of wind noise at the A pillar.

|

|

|

|

12-01-2020, 03:17 PM

12-01-2020, 03:17 PM

|

#17 (permalink)

|

|

Banned

Join Date: Nov 2017

Location: Australia

Posts: 2,060

Thanks: 107

Thanked 1,608 Times in 1,137 Posts

|

Quote:

Originally Posted by serialk11r

Does this have any effect on noise? What about the vortex generators?

I'm asking since I am going to be driving a lot of highway miles and the Infiniti G35 I bought has a ton of wind noise at the A pillar.

|

The ones I fitted didn't but I think that on some cars, either the turning vanes or small VGs could have an impact on wind noise. Easy to test. |

|

|

|

12-03-2020, 02:15 PM

12-03-2020, 02:15 PM

|

#18 (permalink)

|

|

Master EcoModder

Join Date: Jan 2012

Location: United States

Posts: 1,756

Thanks: 104

Thanked 407 Times in 312 Posts

|

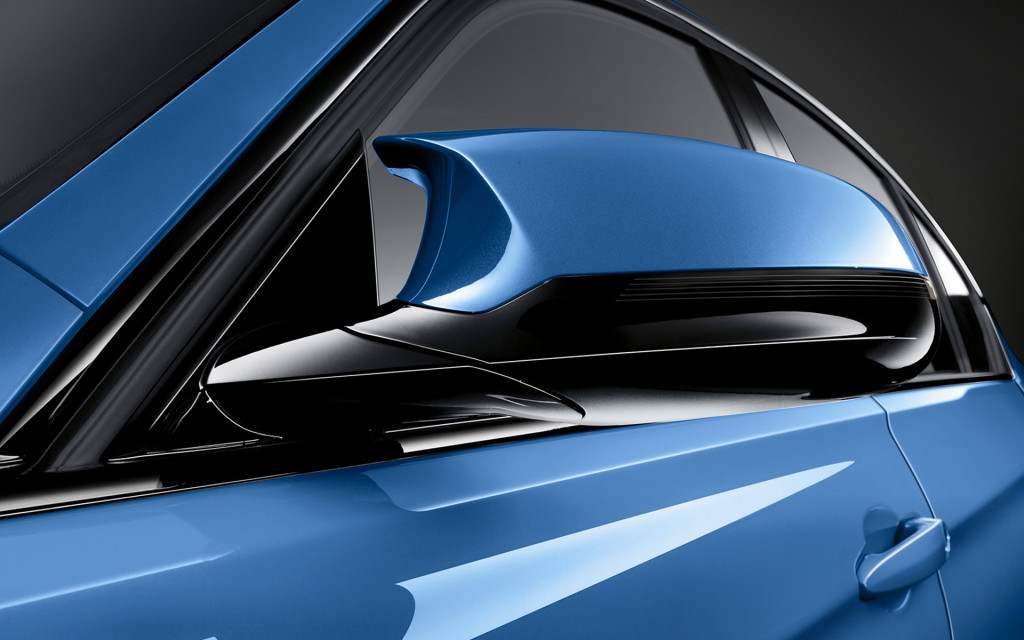

Thanks. My wild guess is that the side mirrors are producing most of the noise, so a VG on the pillar near the top of the mirror would have the best shot at improving things (BMW uses a little fin at the top of the mirror for example).

Since the flow around the windshield is sort of angled upward, I was thinking a small piece of aluminum angle placed flat would generate a vortex and help the air wrap around the pillar and not buffet in the gap to the mirror. Those reusable sticky pads would allow easy removal and experimentation.

|

|

|

|

12-03-2020, 03:27 PM

12-03-2020, 03:27 PM

|

#19 (permalink)

|

|

Master EcoModder

Join Date: Aug 2012

Location: northwest of normal

Posts: 29,410

Thanks: 8,365

Thanked 9,125 Times in 7,534 Posts

|

On the assumption (I know) that the noise comes from a vortex street shedding off the body of the mirror maybe a solution could be found with tiny vortex generators or wickerbills on the mirror itself.

What does BMW's fin look like?

__________________

.

.Without freedom of speech we wouldn't know who all the idiots are. -- anonymous poster

___________________

.

.tragectory: Line goes down and to the right.

|

|

|

|

12-04-2020, 01:36 AM

12-04-2020, 01:36 AM

|

#20 (permalink)

|

|

Master EcoModder

Join Date: Jan 2012

Location: United States

Posts: 1,756

Thanks: 104

Thanked 407 Times in 312 Posts

|

They've had these since the E90 generation on most of the cars. I assume it must be useful.

|

|

|

|

|

The Following User Says Thank You to serialk11r For This Useful Post:

|

|

|