01-24-2010, 06:30 PM

01-24-2010, 06:30 PM

|

#11 (permalink)

|

|

ecomonkey

Join Date: Dec 2009

Location: middleburg fl

Posts: 240

Thanks: 33

Thanked 30 Times in 21 Posts

|

the increased energy of solonoids would be counter acted by not having friction and heat losses from cam ,lifters and rockers, i dont know if it would equal out or not but as far as sensers,solonoids and pulse width modulation control, none of that would be that big of a factor in a giant mass production setup, if i recall from the article though ford stated problems with high rpm operation ,i wish i could remember the issue# of hotrod mag, hoepfully though battery powered cars make the ice obsolute soon.

|

|

|

|

Today Today

|

|

|

|

Other popular topics in this forum...

Other popular topics in this forum...

|

|

|

|

01-24-2010, 06:33 PM

01-24-2010, 06:33 PM

|

#12 (permalink)

|

|

...beats walking...

Join Date: Jul 2009

Location: .

Posts: 6,190

Thanks: 179

Thanked 1,525 Times in 1,126 Posts

|

...one definite "benefit" for ICE would be: infinite valve-train variability over the whole engine rpm range, unlike current VVT-I applications.

|

|

|

|

01-25-2010, 10:28 PM

01-25-2010, 10:28 PM

|

#13 (permalink)

|

|

ecomonkey

Join Date: Dec 2009

Location: middleburg fl

Posts: 240

Thanks: 33

Thanked 30 Times in 21 Posts

|

what about instead of conventinal tulip valves and solonoids, put a spinning disk with holes in it mounted to electric motor/motors then the problem might be sealing,and scyning up the spinning valve disk with the crank, and how would the engine react to having a strait shot to the intake and exaust with no tulip valve in its path (might not even run)

|

|

|

|

01-25-2010, 10:30 PM

01-25-2010, 10:30 PM

|

#14 (permalink)

|

|

...beats walking...

Join Date: Jul 2009

Location: .

Posts: 6,190

Thanks: 179

Thanked 1,525 Times in 1,126 Posts

|

...reed valves like 2-stokes used to use?

...or, sliding valves as Wankel engines have?

|

|

|

|

01-25-2010, 11:47 PM

01-25-2010, 11:47 PM

|

#15 (permalink)

|

|

ecomonkey

Join Date: Dec 2009

Location: middleburg fl

Posts: 240

Thanks: 33

Thanked 30 Times in 21 Posts

|

a spinning disc with a hole/holes in it spun by an electric motor. it does away with the bad reliability of the solonoids,but would require some major cylinder head mods and probably be hard to scyn up since it would have no mecanical connection to the crankshaft, thus the opening and closing event timing advantage,but im sure a new host of challanges, i dont know much about the wankle but probably the same type of valve except spinning instead of sliding.

|

|

|

|

01-25-2010, 11:52 PM

01-25-2010, 11:52 PM

|

#16 (permalink)

|

|

Moderate your Moderation.

Join Date: Nov 2008

Location: Troy, Pa.

Posts: 8,919

Pasta - '96 Volkswagen Passat TDi 90 day: 45.22 mpg (US)

Thanks: 1,369

Thanked 430 Times in 353 Posts

|

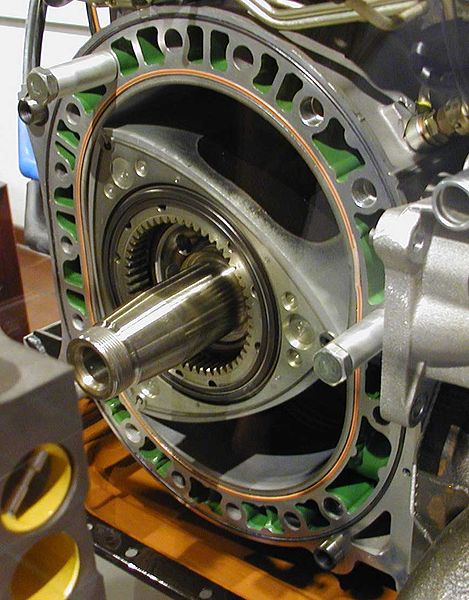

Wankel rotary engines don't have valves, they rely on induction and expansion/compression to move air.

If one wanted to really push the definition, the rotor itself acts as both piston and valve in comparison to a Piston ICE. Each rotor in a Wankel rotary engine effectively does the work of 3 pistons, since all 3 out of 4 phases are always occurring on the 3 faces of the rotor.

__________________

"¿ʞɐǝɹɟ ɐ ǝɹ,noʎ uǝɥʍ 'ʇı ʇ,usı 'ʎlǝuol s,ʇı"

|

|

|

|

01-25-2010, 11:54 PM

01-25-2010, 11:54 PM

|

#17 (permalink)

|

|

...beats walking...

Join Date: Jul 2009

Location: .

Posts: 6,190

Thanks: 179

Thanked 1,525 Times in 1,126 Posts

|

..."sliding" seals wipe across intake and exhaust opens in a Wankel.

|

|

|

|

01-25-2010, 11:57 PM

01-25-2010, 11:57 PM

|

#18 (permalink)

|

|

Moderate your Moderation.

Join Date: Nov 2008

Location: Troy, Pa.

Posts: 8,919

Pasta - '96 Volkswagen Passat TDi 90 day: 45.22 mpg (US)

Thanks: 1,369

Thanked 430 Times in 353 Posts

|

The only seals in the engine are the front/rear oil seals, and the apex seals. I've rebuilt about 40 of them.

The black ring is a front rotor seal, it keeps oil from getting into the swept area. The ports in a Wankel engine are always open, there is nothing resembling a valve. Air is drawn in via induction as the rotor passes the inlet port, and is expelled via compression and expansion as the rotor tip passes the exhaust port.

__________________

"¿ʞɐǝɹɟ ɐ ǝɹ,noʎ uǝɥʍ 'ʇı ʇ,usı 'ʎlǝuol s,ʇı"

|

|

|

|

01-26-2010, 12:03 AM

01-26-2010, 12:03 AM

|

#19 (permalink)

|

|

...beats walking...

Join Date: Jul 2009

Location: .

Posts: 6,190

Thanks: 179

Thanked 1,525 Times in 1,126 Posts

|

...looks to me (and my book) that the apex seals "wipe" across both the intake and exhaust ports three times per revolution, but only once per seal per revolution.

...the side seals, however, act like compression control rings and do not contact either intake or exhaust ports.

|

|

|

|

01-26-2010, 12:09 AM

01-26-2010, 12:09 AM

|

#20 (permalink)

|

|

Moderate your Moderation.

Join Date: Nov 2008

Location: Troy, Pa.

Posts: 8,919

Pasta - '96 Volkswagen Passat TDi 90 day: 45.22 mpg (US)

Thanks: 1,369

Thanked 430 Times in 353 Posts

|

That's an oversimplified view, the inlet port is side-swept, and the exhaust port is the only one that ever gets swept by the apex seals. The apex seals are only designed to act as "piston rings", though. They seal combustion gasses. The sealing rings around the rotors are oil-control.

The side seals don't seal very well, and fail quickly, which is why rotaries burn oil and suck at emissions testing. Mazda requires a special synthetic oil be used in the Renesis engine for this exact reason. (They may have changed the requirement, by now.)

Here's the construction video:

The big deal with rotaries not making much low-end power or torque is due mostly in part to the fact that the engine itself is a 3:1 overdrive. For each revolution of the eccentric shaft, there is one combustion event, and the rotor turns 1/3 of a turn. This means that 9,000 RPM in a rotary is the spinning equivalent of 3,000 in a piston engine, only the rotary has much less capacity per combustion event and far less weight, moving parts, and complexity. There is also no violent changing of direction in a rotary engine, the rotors spin one way, the eccentric shaft spins the other way. The engine is essentially self-balancing.

__________________

"¿ʞɐǝɹɟ ɐ ǝɹ,noʎ uǝɥʍ 'ʇı ʇ,usı 'ʎlǝuol s,ʇı"

Last edited by Christ; 01-26-2010 at 12:16 AM..

|

|

|

|

|