04-21-2011, 10:18 AM

04-21-2011, 10:18 AM

|

#1 (permalink)

|

|

Administrator

Join Date: Dec 2007

Location: Germantown, WI

Posts: 11,203

Thanks: 2,501

Thanked 2,589 Times in 1,555 Posts

|

Anyone ever rewind a motor? (series wound DC)

I have an otherwise good motor that I burnt up a while back (over heated it). I was quoted $300+ to have it rewound at a shop, and thats just a bit too much for me. But, I wouldn't mind taking a crack at repairing/rewinding it myself if its possible. Has anyone ever done anything like this, or know of a good tutorial online, or just tips or info that might help.

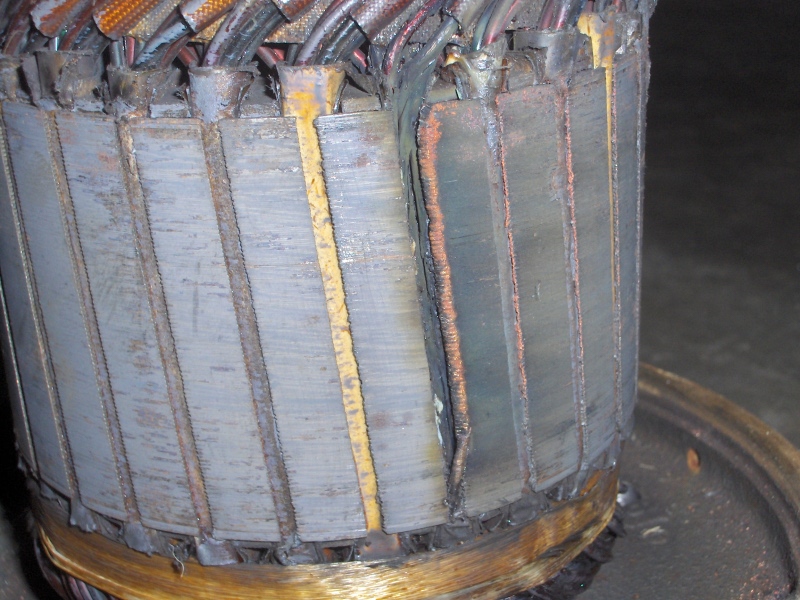

Here are images of the damage:

This is the other side (180 degrees the other damaged area):

|

|

|

|

Today Today

|

|

|

|

Other popular topics in this forum...

Other popular topics in this forum...

|

|

|

|

04-21-2011, 11:20 AM

04-21-2011, 11:20 AM

|

#2 (permalink)

|

|

Batman Junior

Join Date: Nov 2007

Location: 1000 Islands, Ontario, Canada

Posts: 22,534

Thanks: 4,082

Thanked 6,979 Times in 3,614 Posts

|

Did the bars between windings get bent? They appear on an angle to the shaft.

This popped up searching "rewinding DC motor" on Youtube:

And there are a bunch of "suggestions" in the sidebar. |

|

|

|

04-21-2011, 11:26 AM

04-21-2011, 11:26 AM

|

#3 (permalink)

|

|

Batman Junior

Join Date: Nov 2007

Location: 1000 Islands, Ontario, Canada

Posts: 22,534

Thanks: 4,082

Thanked 6,979 Times in 3,614 Posts

|

Doh! In part 5 he burned up his rewound motor.

YMMV!

But it does appear there are more than a few vids of intrepid modders attempting this task. |

|

|

|

04-21-2011, 12:14 PM

04-21-2011, 12:14 PM

|

#4 (permalink)

|

|

Making Ecomods a G thing

Join Date: Jan 2011

Location: Illinois

Posts: 655

Thanks: 35

Thanked 75 Times in 58 Posts

|

i've rewound small DC motors before, but none like that one. it's a daunting task either way though, should be relatively easy to find information online.

__________________

|

|

|

|

04-21-2011, 12:30 PM

04-21-2011, 12:30 PM

|

#5 (permalink)

|

|

needs more cowbell

Join Date: Feb 2008

Location: ÿ

Posts: 5,038

Thanks: 158

Thanked 269 Times in 212 Posts

|

I've had my starter rebuilt locally for like $70. How big is that motor?

The rc guys do this stuff a lot, on a smaller scale. Some ambituous types have rewound motors to suit different supply voltages as well (i.e. thinner wire and more turns for higher voltage supply, works the other way also).

http://www.eng-tips.com/viewthread.c...194110&page=94

__________________

WINDMILLS DO NOT WORK THAT WAY!!!

|

|

|

|

04-21-2011, 12:39 PM

04-21-2011, 12:39 PM

|

#6 (permalink)

|

|

Administrator

Join Date: Dec 2007

Location: Germantown, WI

Posts: 11,203

Thanks: 2,501

Thanked 2,589 Times in 1,555 Posts

|

The motor is 7" in diameter and probably 8" long. Its rated for 24V / 64A. I was using for my electric riding lawn mower, but it proved a bit too small for the application (without additional cooling).

|

|

|

|

04-21-2011, 01:49 PM

04-21-2011, 01:49 PM

|

#7 (permalink)

|

|

kir_kenix

Join Date: Sep 2010

Location: Emerson, Ne

Posts: 207

Thanks: 15

Thanked 30 Times in 19 Posts

|

we've had a few motors (farm applications) rewound locally. Not sure what it cost exactly for one off's since we have a large account with them, but I could look into for you if you want. Never been ambitious enough to try it myself, but it would sure be interesting to give it a try.

Most of what we have rewound are 10" motors that run belts in the chicken houses. I keep eyeing them everytime I'm back home...electric escort anyone? Maybe give it a better look once school is out.

|

|

|

|

04-25-2011, 11:08 PM

04-25-2011, 11:08 PM

|

#8 (permalink)

|

|

EcoModding Apprentice

Join Date: Dec 2010

Location: southern indiana

Posts: 126

Thanks: 0

Thanked 5 Times in 5 Posts

|

electric escort sounds great cant wait for that build

|

|

|

|

04-26-2011, 12:12 AM

04-26-2011, 12:12 AM

|

#9 (permalink)

|

|

MPG Militia HMV-25E80+A

Join Date: Mar 2011

Location: Vermont, USA

Posts: 823

Thanks: 191

Thanked 144 Times in 98 Posts

|

MetroMPG, IIRC, the twist that you see is supposed to be there to make the rotation smoother. It has to do with the magnetic feild being pulled less like a pulse and more at an angle. They do the same things with generator windings.

Personally, it is WAY more dificult to rewind your windings yourself than have it done. It can be done, I've rewound one generator rotor( 4 pole) and never again. If you are going to try it yourself, before you buy any new wire, try unwinding it, by hand, trying not to chip any more of the laquer off the wire. Test some of the windings to make sure they are still good( no grounds or opens), some will be, and see if they are still good after you are done removing them. A meger is a good tool to have when attempting this. Of course, it can also be used to burn up windings as well.

Best of luck  |

|

|

|

04-26-2011, 11:24 AM

04-26-2011, 11:24 AM

|

#10 (permalink)

|

|

EcoModding Lurker

Join Date: Feb 2011

Location: indiana

Posts: 16

Thanks: 5

Thanked 3 Times in 3 Posts

|

The whole world runs on smoke. Electricity is just another form smoke. Once you've let it out you'll never get it back in there.

But seriously rewinding that motor will prove to be a daunting task for someone with no experience. I don't say that to discourage you from learning something new by any means just know it's not as easy as it looks. You may beat $300 at a local rewind shop given the size of that one but not by much there is a lot of copper in there and the bars need to be dressed up. A good shop should replace the bearings and properly seat the brushes as well (not let them wear themselves into full contact with the commutator). Just out of curiosity what does the stator look like? Should you decide to attempt yourself keep it posted I would love to see your progress.

|

|

|

|

|