10-22-2015, 06:09 AM

10-22-2015, 06:09 AM

|

#11 (permalink)

|

|

Master EcoModder

Join Date: May 2008

Location: UK

Posts: 333

Thanks: 16

Thanked 79 Times in 54 Posts

|

I seem to recall a JDM aftermarket device which had a vacuum controlled butterfly valve. Or it might have been electronically controlled. It was made by HKS or some such. I could imagine the severe environment of an exhaust pipe causing problems for such a device.

|

|

|

|

Today Today

|

|

|

|

Other popular topics in this forum...

Other popular topics in this forum...

|

|

|

|

10-22-2015, 03:01 PM

10-22-2015, 03:01 PM

|

#12 (permalink)

|

|

.........................

Join Date: Aug 2009

Location: Buckley, WA

Posts: 1,597

Thanks: 391

Thanked 488 Times in 316 Posts

|

Quote:

Originally Posted by Daschicken

My grandpa's 1999 yamaha r1 had an exhaust butterfly valve, but I doubt it was computer controlled as the thing had carbs. Although it did have a MIL system that had codes for the exhaust valve, so it could be.

|

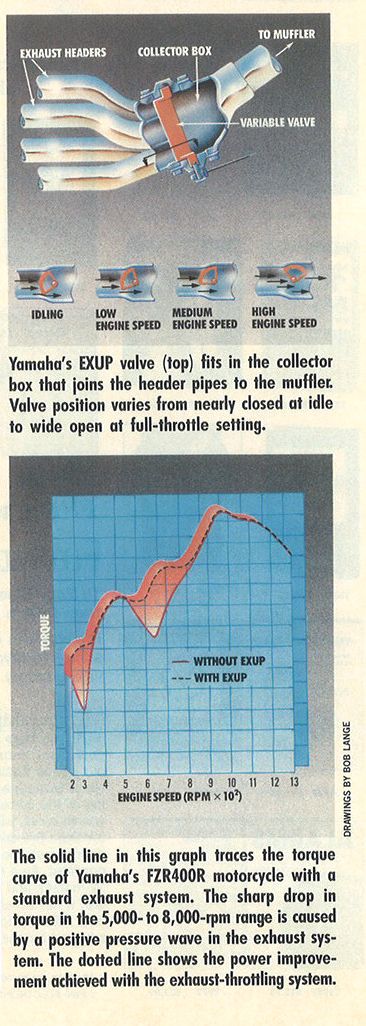

This is Yamaha's EXUP system, and the computer module controls when the valve opens and closes. I have the same engine on my bike-engined-car project, and have to defeat the system in order to allow the engine to run properly even though it is carbureted.

It's not entirely accurate to say this system increases backpressure. The header should be tuned for optimal scavenging at whatever RPM peak torque is made at. Restricting the exhaust adjusts the exhaust pulses to better scavenge at low RPMs. This actually reduces backpressure at the exhaust valve when the exhaust valve opens.

For a dedicated economy car, rather than try to replicate this complex exhaust valve system, you'd be better off designing a header that is tuned for running at low RPMs. That would be cheaper and far easier to accomplish, and likely more effective. Although, I doubt you will see measureable gains over the stock exhaust. |

|

|

|

|

The Following User Says Thank You to darcane For This Useful Post:

|

|

11-13-2015, 11:21 PM

11-13-2015, 11:21 PM

|

#13 (permalink)

|

|

EcoModding Lurker

Join Date: Oct 2015

Location: Great White North

Posts: 9

Thanks: 1

Thanked 2 Times in 1 Post

|

Some of the latest gen Corvette's (C7) have butterfly valves in the exhaust, the Ferrari 458 has an additional exhaust chamber that is opened at full chat. I also thought of a dilating cone type valve like on the exhaust of a fighter jet, very exotic and would need to be designed properly so as not to jam up from road crud, but I have been tooling with metal from soda cans to create a prototype, seems feasible using a simple cable linkage and return spring.

|

|

|

|

11-14-2015, 03:32 AM

11-14-2015, 03:32 AM

|

#14 (permalink)

|

|

It's all about Diesel

Join Date: Oct 2012

Location: Porto Alegre, Rio Grande do Sul, Brazil

Posts: 12,947

Thanks: 0

Thanked 1,701 Times in 1,519 Posts

|

In motorcycles those "power valves" were meant to improve the low-end torque, but nowadays with dual-VVT becoming widespread they would become likely redundant.

|

|

|

|

11-25-2015, 05:13 PM

11-25-2015, 05:13 PM

|

#15 (permalink)

|

|

Master EcoModder

Join Date: Jan 2008

Location: Sanger,Texas,U.S.A.

Posts: 16,404

Thanks: 24,471

Thanked 7,410 Times in 4,800 Posts

|

dilating cone

Quote:

Originally Posted by GreenSquirrel

Some of the latest gen Corvette's (C7) have butterfly valves in the exhaust, the Ferrari 458 has an additional exhaust chamber that is opened at full chat. I also thought of a dilating cone type valve like on the exhaust of a fighter jet, very exotic and would need to be designed properly so as not to jam up from road crud, but I have been tooling with metal from soda cans to create a prototype, seems feasible using a simple cable linkage and return spring.

|

Check out this link.It's for the Me 262,Junkers JUMO 004 turbojet tailpipe bullet valve.These are also used in Pelton Wheel turbine water jets.

They're the most fluid dynamically efficient restriction valving I've ever seen and basis for the grille block on my truck.

http://greyfalcon.us/jumo.jpg

__________________

Photobucket album: http://s1271.photobucket.com/albums/jj622/aerohead2/

|

|

|

|

11-27-2015, 10:09 PM

11-27-2015, 10:09 PM

|

#16 (permalink)

|

|

DieselMiser

Join Date: Jun 2008

Location: Richland,WA

Posts: 985

Thanks: 46

Thanked 232 Times in 160 Posts

|

Quote:

Originally Posted by Old Tele man

...or, you can buy software programs that simulate just about 100%-functions of an engine in operation...at any load...under any weather conditions.

|

You can get software like that for free. You just need a PHD to figure how to use it.

Its called OpenFOAM

__________________

|

|

|

|

11-28-2015, 02:53 PM

11-28-2015, 02:53 PM

|

#17 (permalink)

|

|

Master EcoModder

Join Date: Jan 2008

Location: Sanger,Texas,U.S.A.

Posts: 16,404

Thanks: 24,471

Thanked 7,410 Times in 4,800 Posts

|

pressure

Quote:

Originally Posted by RustyLugNut

It is used daily in industry. Lay people see it as "unscientific and variable". Granted, the lab dyno does allow control of certain variables, however, in the case of exhaust back pressure versus load and fuel use, all one needs is a set of accurately mapped fuel injectors/pump for fuel flow and an in-cylinder pressure sensor to see power potential as well as an exhaust pressure sensor and position sensor on your exhaust backpressure valve.

A baseline run followed by a set exhaust valve run yields a pair of pressure traces that allow you to determine a gain or loss. No need to calculate BSFC as combustion pressure is all the feedback you need. A pair of runs takes 5 minutes or less. A well thought out set of runs can yield a reasonably extrapolated pressure map with which to program an engine map.

Again, there is no need to carry the burden of a dyno cell instrument set. In-cylinder pressure will tell you if the exhaust back pressure is beneficial or detrimental. I would probably add a stepper actuator to the exhaust back pressure valve to make "fanning" the back pressure during runs possible. This reduces the number of runs during your data gathering.

|

Yes,it looks like BSFC mirrors torque,which mirrors Mean Effective Pressure,which mirrors the Unit Air Charge.

As long as the before and after runs were done at a constant 'atmosphere',or corrected to a standard atmosphere,it would be really useful data.Thanks!

__________________

Photobucket album: http://s1271.photobucket.com/albums/jj622/aerohead2/

|

|

|

|

11-28-2015, 03:03 PM

11-28-2015, 03:03 PM

|

#18 (permalink)

|

|

Master EcoModder

Join Date: Jan 2008

Location: Sanger,Texas,U.S.A.

Posts: 16,404

Thanks: 24,471

Thanked 7,410 Times in 4,800 Posts

|

difference

Quote:

Originally Posted by Xist

Aerohead, do you remember approximately what kind of a difference that setup made for that motorcycle?

|

Here is the engine map for the YAMAHA EXUP system.You can see how the torque profile is flattened

*I have a HONDA MC exhaust with valving,but just a butterfly valve,nothing as exotic as YAMAHA.

*Walker has been offering a passive/active,Dyno Max VT,valved exhaust since around 2011.

* The new Corvette Sting ray comes standard with a butterfly-valved,DUAL MODE exhaust that's good for 5-bhp.

*Camaro SS has a $895 Dual Mode option.

*I think Ferrari is doing it too,they talk of 'opening baffles'.

*Dinan High Performance Exhaust offers a butterfly-valved exhaust system for the BMW M5.

*Ford offers manually-removable exhaust inserts for their MUSTANG Boss 302,to make the exhaust louder.

PS,the Yamaha EXUP Patent would have expired in 2008?

__________________

Photobucket album: http://s1271.photobucket.com/albums/jj622/aerohead2/

Last edited by aerohead; 12-02-2015 at 07:23 PM..

Reason: organize and add data

|

|

|

|

12-14-2015, 02:35 AM

12-14-2015, 02:35 AM

|

#19 (permalink)

|

|

It's all about Diesel

Join Date: Oct 2012

Location: Porto Alegre, Rio Grande do Sul, Brazil

Posts: 12,947

Thanks: 0

Thanked 1,701 Times in 1,519 Posts

|

Quote:

Originally Posted by aerohead

the Yamaha EXUP Patent would have expired in 2008?

|

Since exhaust-brakes have been around in Diesel trucks for a long time, and their position inside the exhaust system is similar, even though their functions are different, I wouldn't really care about Yamaha and its patents

|

|

|

|

|