02-20-2018, 12:16 AM

02-20-2018, 12:16 AM

|

#21 (permalink)

|

|

Moderator

Join Date: Feb 2012

Location: Urbana, IL

Posts: 1,939

Thanks: 199

Thanked 1,807 Times in 943 Posts

|

Quote:

Originally Posted by freebeard

And the lack of high-speed production is down to the vacuum-bagged autoclaving. It's purpose is to minimize the amount of binder — epoxy or whatever — in ratio to the fibers, to maximize strength (toughness, whatever) for weight.

|

Same is true for fiberglass and resin--too much resin actually weakens the final product at the same time as it's heavier than it needs to be. All those "crap" homemade carbon pieces probably suffered from this.

To my knowledge, the autoclave process does not harden the fibers themselves. I've examined smashed bicycle frames, for instance, where the fibers tore, and they're still quite flexible.

With carbon fiber, you have to look at where the force is applied and in what direction. Depending how you orient and lay the sheets, the finished product will be stronger in one direction than another. Those bicycle forks, for instance, were not designed to resist a concentrated force on the side of one leg; they were designed to resist vertical forces from the mass of the rider transferred to the wheel and then road. (Same theory as a spoked bicycle wheel--they can be quite strong vertically, but you can easily pull a tensioned spoke from the side and rip it out of the hub or rim). Gram for gram, carbon fiber bikes are much stronger than steel or aluminum, and thus can be made lighter (and made into complex shapes more easily). They're also more comfortable than aluminum, as carbon fiber absorbs more road vibration.

|

|

|

|

Today Today

|

|

|

|

Other popular topics in this forum...

Other popular topics in this forum...

|

|

|

|

02-20-2018, 02:06 AM

02-20-2018, 02:06 AM

|

#22 (permalink)

|

|

Master EcoModder

Join Date: Aug 2012

Location: northwest of normal

Posts: 29,338

Thanks: 8,345

Thanked 9,109 Times in 7,522 Posts

|

I forgot one. The big competitor might turn out to be densified wood. https://www.scientificamerican.com/a...-s-super-wood/

Quote:

Now, Hu and his colleagues say they have come up with a better way to densify wood, which they report in the February 7 Nature. Their simple, two-step process starts with boiling wood in a solution of sodium hydroxide (NaOH) and sodium sulfite (Na2SO3), a chemical treatment similar to the first step in creating the wood pulp used to make paper. This partially removes lignin and hemicellulose (natural polymers that help stiffen a plant’s cell walls)—but it largely leaves the wood’s cellulose (another natural polymer) intact, Hu says.

The second step is almost as simple as the first: Compressing the treated wood until its cell walls collapse, then maintaining that compression as it is gently heated. The pressure and heat encourage the formation of chemical bonds between large numbers of hydrogen atoms and neighboring atoms in adjacent nanofibers of cellulose, greatly strengthening the material.

The results are impressive. The team’s compressed wood is three times as dense as the untreated substance, Hu says, adding that its resistance to being ripped apart is increased more than 10-fold. It also can become about 50 times more resistant to compression and almost 20 times as stiff. The densified wood is also substantially harder, more scratch-resistant and more impact-resistant. It can be molded into almost any shape. Perhaps most importantly, the densified wood is also moisture-resistant: In lab tests, compressed samples exposed to extreme humidity for more than five days swelled less than 10 percent—and in subsequent tests, Hu says, a simple coat of paint eliminated that swelling entirely.

A five-layer, plywoodlike sandwich of densified wood stopped simulated bullets fired into the material—a result Hu and his colleagues suggest could lead to low-cost armor. The material does not protect quite as well as a Kevlar sheet of the same thickness—but it only costs about 5 percent as much, he notes.

|

They then go on to discuss a transparent wood-Lucite composite!

__________________

.

.Without freedom of speech we wouldn't know who all the idiots are. -- anonymous poster

___________________

.

.Impossible is just something we haven't done yet. -- Langley Outdoors Academy

|

|

|

|

02-20-2018, 09:17 AM

02-20-2018, 09:17 AM

|

#23 (permalink)

|

|

Banned

Join Date: Feb 2018

Location: Brazil

Posts: 1,476

Thanks: 14

Thanked 363 Times in 327 Posts

|

It's too much information... Jesus...

It would lead to dozen possible combinations. I want to know about the average carebon fiber made in small garages/home, following rightfully the manufacturer specifications, without autoclave or ovens.

The worse carbon fiber fabric sheet, if well used, is at least 3 or 4 times stronger than steel.

About the weigh be the right reference to comparison with steel, in this video about failure of carbon fiber, the weight it's not so different, near aluminiun weight and more more than 50% the weight of steel.

CF: 1.15

Aluminium: 1.45

Steel: 2.16

If you work or had worked with carbon fiber, I apologyse if my comments sounded rude ar unkind. Maybe it's just some ignorance of mine about some technical aspect somewhere.

Maybe the best would be the composite used in Aptera car, made of silica, strong to resist hammer impact, aborbing energy by some few deforming (reversible if not much). But we don't know the price for such materail and labor.

https://youtu.be/nvk63bmVpck?t=41

Quote:

Originally Posted by Piotrsko

Ok but I need several parameters defined: weight / mass of finished product, resistance to how much force applied where and how, binder materials and their specs, resins specs for filling the matrix, cure process, Attach points, etc. If it is a simple pull test then the comparison can be done easy peesey. How strong is 10 mill steel 1" wide? (I already know this.

Btw when you say home made, what do you really mean?

|

|

|

|

|

02-20-2018, 09:48 AM

02-20-2018, 09:48 AM

|

#24 (permalink)

|

|

Master EcoModder

Join Date: Jul 2011

Location: Ann Arbor, Michigan

Posts: 4,210

Thanks: 140

Thanked 2,824 Times in 1,981 Posts

|

Quote:

Originally Posted by All Darc

Maybe the best would be the composite used in Aptera car, made of silica, strong to resist hammer impact, aborbing energy by some few deforming (reversible if not much). But we don't know the price for such materail and labor.

|

I looked that and found this:

https://www.reviewjournal.com/uncate...-entirely-new/

Quote:

|

A composite silica fiber body is built around a honeycomb foam core, like an airplane wing. It is lightweight but also three times stronger than steel.

|

Also read a story about disenchanted workers taking forklifts and crushing some body shells in spite, posted on Youtube it said.

__________________

George

Architect, Artist and Designer of Objects

2012 Infiniti G37X Coupe

1977 Porsche 911s Targa

1998 Chevy S-10 Pick-Up truck

1989 Scat II HP Hovercraft

You cannot sell aerodynamics in a can............

|

|

|

|

02-20-2018, 10:53 AM

02-20-2018, 10:53 AM

|

#25 (permalink)

|

|

Thalmaturge

Join Date: Mar 2011

Location: The edge of nowhere

Posts: 1,167

Thanks: 769

Thanked 647 Times in 432 Posts

|

Every time I see those videos I get angry.

Such a beautiful car, destroyed by a bunch of pump-and-dumpers.

|

|

|

|

02-20-2018, 11:11 AM

02-20-2018, 11:11 AM

|

#26 (permalink)

|

|

Master EcoModder

Join Date: Aug 2012

Location: northwest of normal

Posts: 29,338

Thanks: 8,345

Thanked 9,109 Times in 7,522 Posts

|

Quote:

|

If you work or had worked with carbon fiber, I apologyse if my comments sounded rude ar unkind. Maybe it's just some ignorance of mine about some technical aspect somewhere.

|

English as a 2n language aside, I went back though the thread and find everyone helpful and un-antagonistic.

Quote:

Stop Saying Things That Make You Weak ...

Jordan Peterson

|

On to the subject of homemade carbon fiber. I haven't worked with it, I don't like stuff that gives off fumes. But my understanding is that carbon fiber is limp but it resists draping. IOW you wind up poking it into recesses and it pops back out. Sorta passive-agressive.

Vacuum bagging is a low-cost way to avoid needing a two-part form, the air pressure is conformal.

Quote:

|

I want to know about the average carebon fiber made in small garages/home, following rightfully the manufacturer specifications, without autoclave or ovens.

|

Simply put, your mileage may vary. Are you making a gear shift knob or a whole car? Do you have a clean dry work space with a finished floor? Working out at the curb or under a tree (like Eastern Oregon)?

We have a member that is in the jungle of Costa Rica, we probably have members is upscale communities in New Zealand.

Why do you disallow vacuum bagging? You can probably do it with a second-hand water bed and a vacuum cleaner.

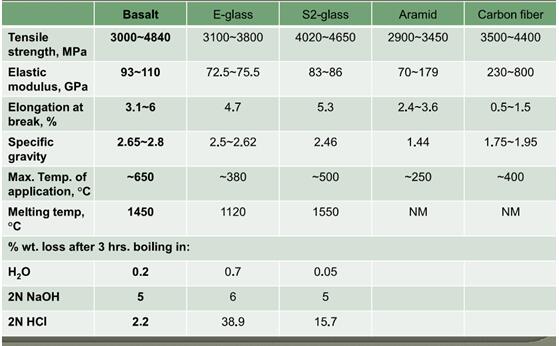

Since you are still poised to dive in, I'd have you consider basalt. https://www.basalt.guru/

http://www.pulwellfrp.com/editor/attached/image/20151204/20151204155935_4556.jpg

http://www.pulwellfrp.com/editor/attached/image/20151204/20151204155935_4556.jpg

Basalt doesn't shatter like carbon fiber, it dents instead. To make an arbitrary shape you could start with an open mesh, cut and stitched, and then lay fabric on to surface it.

The challenge is completely wetting the fibers without excessive resin.

__________________

.

.Without freedom of speech we wouldn't know who all the idiots are. -- anonymous poster

___________________

.

.Impossible is just something we haven't done yet. -- Langley Outdoors Academy

|

|

|

|

02-20-2018, 11:31 AM

02-20-2018, 11:31 AM

|

#27 (permalink)

|

|

Banned

Join Date: Feb 2018

Location: Brazil

Posts: 1,476

Thanks: 14

Thanked 363 Times in 327 Posts

|

Sorry, only now I saw this post of yours.

Interesting, and it's true, but I read about they use CF sheets in layers with different fiber orientations, to get strong in many directions.

And the simple fact of use a region with local angle different, turn it less prone to bend (flexible in a given direction). For othjer side less flexible also means more prone tp broke :

But watching videos like this,

I can't imagine/feel it as stronger than still. 270 nestons are not much, since a little hydraulic shock absorber used in closets or kitchen cabinets have 150 newtons.

Carbon fiber it's a cable, a strong cable on a jail of epoxi resin. If epoxi resin are not strong enough to keep the fiber on jail under pressure... we have a problem.

Again, one more crap carbon fiber product :

Who knows a carbon fiber product for sale that do not behave like a crap ?

Quote:

Originally Posted by Vman455

With carbon fiber, you have to look at where the force is applied and in what direction. Depending how you orient and lay the sheets, the finished product will be stronger in one direction than another. Those bicycle forks, for instance, were not designed to resist a concentrated force on the side of one leg; they were designed to resist vertical forces from the mass of the rider transferred to the wheel and then road. (Same theory as a spoked bicycle wheel--they can be quite strong vertically, but you can easily pull a tensioned spoke from the side and rip it out of the hub or rim). Gram for gram, carbon fiber bikes are much stronger than steel or aluminum, and thus can be made lighter (and made into complex shapes more easily). They're also more comfortable than aluminum, as carbon fiber absorbs more road vibration.

|

Like the feeling of watch EV-1 holocaust ?

Maybe these aptera's shells wasn't finished, not all layers, or the little car that puledl it against the wal was really very strong.

Anyway his topic is going about to be collection of "Super Material" going fail. What is the kryptonite of all that stuff?

Quote:

Originally Posted by samwichse

Every time I see those videos I get angry.

Such a beautiful car, destroyed by a bunch of pump-and-dumpers.

|

Last edited by All Darc; 02-20-2018 at 11:53 AM..

|

|

|

|

02-20-2018, 12:16 PM

02-20-2018, 12:16 PM

|

#28 (permalink)

|

|

Human Environmentalist

Join Date: Aug 2010

Location: Oregon

Posts: 13,020

Thanks: 4,375

Thanked 4,554 Times in 3,500 Posts

|

Quote:

Originally Posted by All Darc

Sorry to disagree with you now. But a rocket it's mostly fuel in weight, so if you cut for the weight of the empty body of a rocket in 99%, it would still be incredible heavy (98,99% of weigh if with fuel added), due the weight of fuel.

A Airplane would take some benefit.

But a car, with only 10% of fuel weight of total weight, and so a90% of weight for the car's body (shape/reels/motor...) and if we could cut 70% of the body weight, the final car (with fuel) would be 40% of the initial car's weight with fuel.

You had reversed the fuel weight important analysis.

|

Most of the fuel in a rocket is consumed merely accelerating the weight of the fuel. To add a small amount of payload or rocket structure, more fuel must be added, but then a lot more fuel must be added to simply accelerate the weight of the additional fuel. For this reason, a small difference in weight translates to big differences in fuel consumption.

Aircraft have a higher payload to fuel ratio than rockets, but it is still not great. Adding a little weight has a medium impact on the additional amount of fuel required.

Automobiles have a very high payload to fuel ratio. Adding a small amount of weight has little impact on the fuel consumed. Add 200lbs to your car and drive 100 miles on the highway, and you won't even be able to tell the difference in fuel consumed. Any fuel consumed going up hill is recaptured coming back down the other side. In fact, moderate hills can be more efficient for driving a petrol car than flat roads (forced pulse and glide).

The higher the ratio of payload to fuel, the less important weight reduction is.

As shown in this forum, aerodynamic improvements are much more effective at improving fuel economy than weight reductions.

Quote:

Originally Posted by All Darc

Carbon fiber it's a cable, a strong cable on a jail of epoxi resin. If epoxi resin are not strong enough to keep the fiber on jail under pressure... we have a problem.

Again, one more crap carbon fiber product :

Who knows a carbon fiber product for sale that do not behave like a crap?

|

As you point out, carbon fiber is strong as long as it is engineered to take advantage of its strengths and avoid its weakness.

How much would a bow rod made of steel weigh? A similar diameter and thickness steel rod could be stronger, but it would also be much heavier.

Most bicycle enthusiasts prefer a carbon fiber front fork both for weight reduction and bump absorption. There are plenty of consumer products where CF is the appropriate material of choice.

Last edited by redpoint5; 02-20-2018 at 12:28 PM..

|

|

|

|

02-20-2018, 12:20 PM

02-20-2018, 12:20 PM

|

#29 (permalink)

|

|

Master EcoModder

Join Date: Aug 2012

Location: northwest of normal

Posts: 29,338

Thanks: 8,345

Thanked 9,109 Times in 7,522 Posts

|

Quote:

|

Anyway [t]his topic is going about to be [a] collection of "Super Material" [that are] going fail. What is the kryptonite of all that stuff?

|

Am I interpreting that correctly? 'Kryptonite' would be Polymetal:

It's prefinished. A 3mm sheet is equal to 5/8" plywood. (The same stuff that clad the Grenfell Tower.)

__________________

.

.Without freedom of speech we wouldn't know who all the idiots are. -- anonymous poster

___________________

.

.Impossible is just something we haven't done yet. -- Langley Outdoors Academy

|

|

|

|

02-20-2018, 02:48 PM

02-20-2018, 02:48 PM

|

#30 (permalink)

|

|

Banned

Join Date: Feb 2018

Location: Brazil

Posts: 1,476

Thanks: 14

Thanked 363 Times in 327 Posts

|

Once you are on the road, the weight it's not very important and aerodynamics it's the main issue. I totally agree with you, in these terms.

But once you are in a ascent/clive, the overal weight it's very important. And every time you need to desaccelerate and accelerate again, like driving in the city, weight became important.

About carbon fiber, I'm judging in pracvtical ways. The products I saw on videos broke too easily. To me this is enough to say carbon fiber, in real world aplications for non miliomaires consumers, it's a crap.

Sure it's great for Formula-1 driver and for the army, but not much for us.

I bet many people are doing carbon fiber in home, paying a ot, to get a poor finished product. They are not NASA to calculate fiber direction interaction model to a given type of impact or forse, to be suitable to given number of specific aplications.

Quote:

Originally Posted by redpoint5

Automobiles have a very high payload to fuel ratio. Adding a small amount of weight has little impact on the fuel consumed. Add 200lbs to your car and drive 100 miles on the highway, and you won't even be able to tell the difference in fuel consumed. Any fuel consumed going up hill is recaptured coming back down the other side. In fact, moderate hills can be more efficient for driving a petrol car than flat roads (forced pulse and glide).

The higher the ratio of payload to fuel, the less important weight reduction is.

As shown in this forum, aerodynamic improvements are much more effective at improving fuel economy than weight reductions.

As you point out, carbon fiber is strong as long as it is engineered to take advantage of its strengths and avoid its weakness.

How much would a bow rod made of steel weigh? A similar diameter and thickness steel rod could be stronger, but it would also be much heavier.

Most bicycle enthusiasts prefer a carbon fiber front fork both for weight reduction and bump absorption. There are plenty of consumer products where CF is the appropriate material of choice.

|

Last edited by All Darc; 02-20-2018 at 03:05 PM..

|

|

|

|

|