01-25-2025, 06:59 AM

01-25-2025, 06:59 AM

|

#1 (permalink)

|

|

Master EcoModder

Join Date: Aug 2022

Location: South Africa

Posts: 874

Thanks: 341

Thanked 350 Times in 303 Posts

|

Greenest = Linear genset series HEV idea

While the whole video and Edison Motors as a whole is interesting, this video from around 11min04 makes the point that a series PHEV is best and most eco:

https://youtu.be/PJEyZEXTLFg?t=664

(check the start for the guys credentials)

Now that's for a heavy truck where the % of weight the genset ads is small relative to the total weight, not an Aptera or something.

There you want the genset to be about as heavy as a small hydrogen balloon for the same maths to work!

When you boil it all down, a Linear Generator is the way to go for the lightest and most eco genset:

The efficiency of a linear engine is (theoretically) WAY better than a std ICE with crankshaft:

Max torque from a crankshaft would be IF the conrod was at 90 degrees to the crank when the piston was at the std 20 deg after TDC where the max pressure on the conrod is currently produced during the power stroke in a std engine...

ie: In today's engines; max pressure is produced when the conrod is more trying to push/'explode' the whole crankshaft, down out of the engine, rather than when its at 90 deg to the crankshaft; the optimal angle for turning it.

That's NOT an issue with linear engines, and is why there's so much research into them...

Also; when the conrod is at an angle relative to piston motion, there is a sideways force on the piston that translates into high friction (and wear) between the piston and sleeve.

That is also NOT an issue with linear engines...

Then there are way fewer to no rotating bearings etc (friction) and the whole engine - generator combo is just way smaller and lighter.

Where their issue lies is in getting their piston to reciprocate in the predictable 'sinusoidal' manner all our EFI and rotating motor and generator software is already geared for...

Research Institutes (Like anyone here givesAF what they say!  ) etc are struggling with getting them just to reciprocate, never mind predictably!

So howTH could some dude build one in his garage!?

The Idea:

A virtual crankshaft...

We have the ignition and EFI tech for real crankshafted engines.

We also have the software etc for high pole count rotating motors.

So a virtual 'sinusoidal', but physically linear crankshaft/motor to run the 3 non powered strokes of say a 4-stroke linear genset is not a 'start from scratch' endeavor.

ie: Making a linear electric motor using current (rotational) software should be easy, so you can drive a non firing linear engine all day, with ease.

I'm guessing that some well placed diodes (to std active PFC etc circuitry and perhaps Supercaps) in the motor circuitry will allow for the power stroke to generate more electricity than the other 3 'motored' strokes take, as it does in stock standard 4-stroke engines today..?

All the research I've seen does NOT start from the standpoint of a virtually rotating, physically reciprocating motor, to build on.

Once the engine is 'turning' one can start looking at optimizing the the virtual CRANKshaft profile in software!!!

(if you want to get technical about Vibration Free linear engines; 2 counter reciprocating pistons is where you end up and that means 2 virtual, electromagnetically driven crankshafts/pistons...)

So this is posted here, simply as an idea, that someone with the equipment and resources (NOT me.  ) to build such an engine might find it.

If you're here looking for a fuel saving device you can go buy at Walmart you're in the wrong place!

Their ant poison (Boric Acid as lubricant) or E-bicycle section is where you should be.

Last edited by Logic; 01-27-2025 at 03:58 AM..

|

|

|

|

|

The Following User Says Thank You to Logic For This Useful Post:

|

|

Today Today

|

|

|

|

Other popular topics in this forum...

Other popular topics in this forum...

|

|

|

|

01-25-2025, 01:04 PM

01-25-2025, 01:04 PM

|

#2 (permalink)

|

|

Master EcoModder

Join Date: Aug 2012

Location: northwest of normal

Posts: 29,407

Thanks: 8,364

Thanked 9,123 Times in 7,533 Posts

|

For the lurkers:

Quote:

Wikipedia

Free-piston linear generator - Wikipedia

A free-piston linear generator (FPLG) is a device that converts chemical energy from fuel into electric energy using magnets and a stator. It has no crankshaft, which makes it lighter, smaller and more efficient than conventional engines.

|

Sounds like applying a Variable Frequency Drive to the piston[s].

__________________

.

.Without freedom of speech we wouldn't know who all the idiots are. -- anonymous poster

___________________

.

.tragectory: Line goes down and to the right.

|

|

|

|

|

The Following 2 Users Say Thank You to freebeard For This Useful Post:

|

|

01-27-2025, 03:36 AM

01-27-2025, 03:36 AM

|

#3 (permalink)

|

|

Master EcoModder

Join Date: Aug 2022

Location: South Africa

Posts: 874

Thanks: 341

Thanked 350 Times in 303 Posts

|

Quote:

Originally Posted by freebeard

For the lurkers:

Sounds like applying a Variable Frequency Drive to the piston[s].

|

More like this:

I don't know if the Libertine (possible new exception..?) is running the linear generator coils/magnets as a motor during the compression stroke, but most all these research motors try to use springs/air-springs and careful tuning of spring rates etc and piston weights etc-etc to get the piston/s to oscillate in a desirable fashion.

NOT the simple running of the the 'generator' as a linear motor.

They all seem to use a 2-stroke cycle with ports to get a power stroke at every 'TDC'.

While much can be done to make the 2-stroke cycle cleaner in these, we currently use 4 strokes and with good reason.

So ye;

Run the pistons as a linear motor, except for the (generator) power stroke is what I am suggesting.

That means starting with available perfected motor and ignition etc electronics/tech, and; 'Take it from there' for 'Tuning for Linear'.

Yes; You will need a Koenigsegg Freevalve type system for 4-strokes.

This guy has DIY done so,

for varying rpm..!

Fixed 'rpm' is easier.

https://www.youtube.com/@WesleyKagan...uery=freevalve

The end result:

Last edited by Logic; 01-27-2025 at 03:45 AM..

|

|

|

|

03-13-2025, 04:55 PM

03-13-2025, 04:55 PM

|

#4 (permalink)

|

|

Master EcoModder

Join Date: Dec 2011

Location: New Zealand

Posts: 5,142

Thanks: 2,930

Thanked 2,603 Times in 1,619 Posts

|

On the face of it, a linear genset really does seem to be the best of all worlds. My impression is that it's a matter of just implementing it, and the time to develop it. It hasn't been all that long since batteries were commonly big enough to provide all the power needs of a vehicle, and this would best work as a way to recharge those batteries, while the batteries remain responsible for motive power.

That said, I have been reading about Mazda's newest genset, and it gives me pause as to whether automakers will even choose (for mainstream) to pursue high efficiency gensets. Mazda's pitch appears to be that, most driving is local and short-haul, and eventually all vehicles will be hybrids of some sort, and have a battery of some size. Batteries are rapidly falling in price, size and weight. For a passenger vehicle, this essentially means driving on the battery most of the time, with access to a charger every night. The point of a genset (according to Mazda) is not really to provide the energy that is used to move the vehicle on a regular basis, but to extend range in those less frequent cases, such as a road trip, and as such their efficiency is relatively unimportant.

Mazda has chosen to develop a rotary for this. My first impression was "are they insane?", given how inefficient and polluting rotaries are. Their reasons, however: rotaries are compact, lightweight, power dense, and smooth. They take up very little room in the vehicle, and their emissions and efficiency are near irrelevant if they're only being used occasionally. So, rather than a vehicle having a 500 mile battery, give it a 100 mile (or whatever is deemed appropriate) battery and a small rotary genset. The vehicle will do 98% of its driving on the battery, the genset will not cause significant compromises to vehicle packaging, and the driver will not feel any range anxiety. Similar in concept to how GM advertised the Volt, and to how BMW designed the i3 REX.

I have personal interest in efficiency, but Mazda seems to be posing the question, "To what end, and at what cost?". Possibly a linear genset could be more compact, cheaper, and more balanced than even a rotary. But, it does need to be developed.

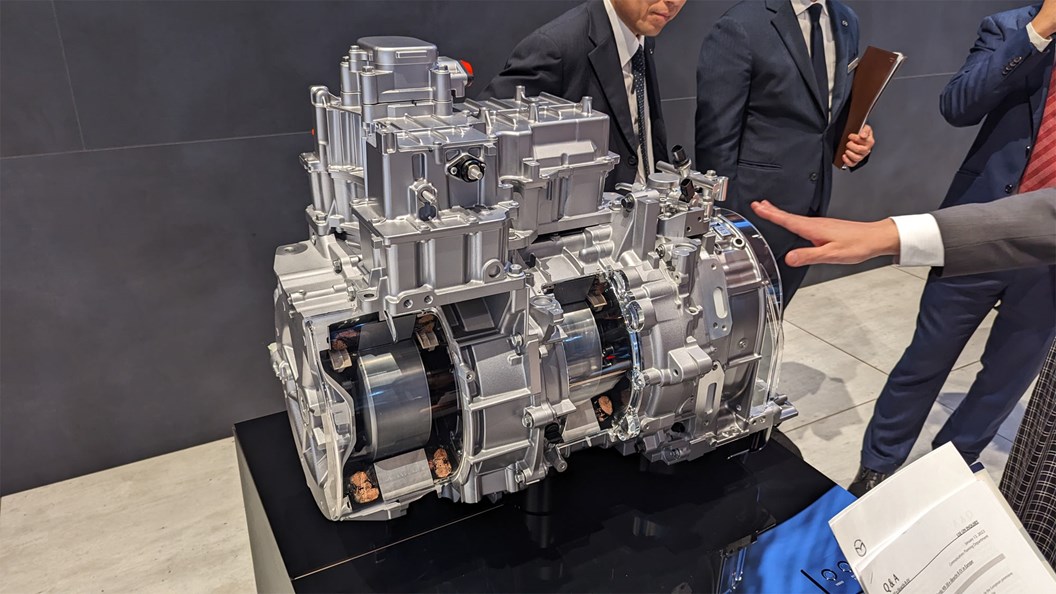

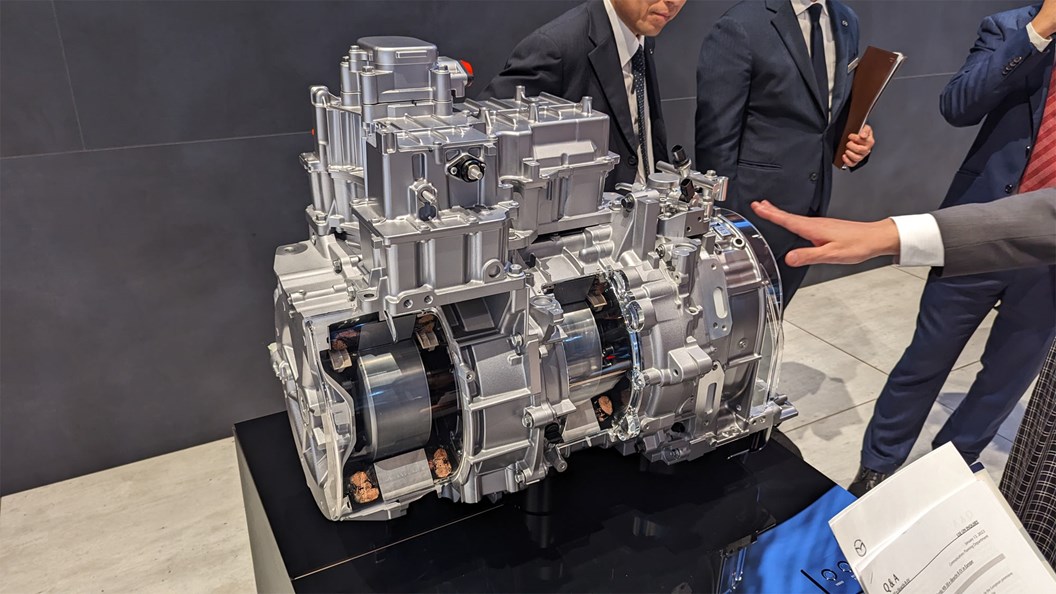

EDIT: A picture of the size of the MX-30 drivetrain. It is 168hp, and weighs less than a typical gasoline engine alone. Mazda choose to attach a rotary, and to equip it with a 130 mile (209km) battery, which weighs about the same as two full tanks of gasoline. The total drivetrain including the EV battery weighs no more than a conventional engine, transmission and full gas tank.

Last edited by Ecky; 03-13-2025 at 05:57 PM..

|

|

|

|

|

The Following 2 Users Say Thank You to Ecky For This Useful Post:

|

|

03-18-2025, 11:09 AM

03-18-2025, 11:09 AM

|

#5 (permalink)

|

|

Master EcoModder

Join Date: Aug 2022

Location: South Africa

Posts: 874

Thanks: 341

Thanked 350 Times in 303 Posts

|

Quote:

Originally Posted by Ecky

On the face of it, a linear genset really does seem to be the best of all worlds. My impression is that it's a matter of just implementing it, and the time to develop it. It hasn't been all that long since batteries were commonly big enough to provide all the power needs of a vehicle, and this would best work as a way to recharge those batteries, while the batteries remain responsible for motive power.

That said, I have been reading about Mazda's newest genset, and it gives me pause as to whether automakers will even choose (for mainstream) to pursue high efficiency gensets. Mazda's pitch appears to be that, most driving is local and short-haul, and eventually all vehicles will be hybrids of some sort, and have a battery of some size. Batteries are rapidly falling in price, size and weight. For a passenger vehicle, this essentially means driving on the battery most of the time, with access to a charger every night. The point of a genset (according to Mazda) is not really to provide the energy that is used to move the vehicle on a regular basis, but to extend range in those less frequent cases, such as a road trip, and as such their efficiency is relatively unimportant.

Mazda has chosen to develop a rotary for this. My first impression was "are they insane?", given how inefficient and polluting rotaries are. Their reasons, however: rotaries are compact, lightweight, power dense, and smooth. They take up very little room in the vehicle, and their emissions and efficiency are near irrelevant if they're only being used occasionally. So, rather than a vehicle having a 500 mile battery, give it a 100 mile (or whatever is deemed appropriate) battery and a small rotary genset. The vehicle will do 98% of its driving on the battery, the genset will not cause significant compromises to vehicle packaging, and the driver will not feel any range anxiety. Similar in concept to how GM advertised the Volt, and to how BMW designed the i3 REX.

I have personal interest in efficiency, but Mazda seems to be posing the question, "To what end, and at what cost?". Possibly a linear genset could be more compact, cheaper, and more balanced than even a rotary. But, it does need to be developed.

EDIT: A picture of the size of the MX-30 drivetrain. It is 168hp, and weighs less than a typical gasoline engine alone. Mazda choose to attach a rotary, and to equip it with a 130 mile (209km) battery, which weighs about the same as two full tanks of gasoline. The total drivetrain including the EV battery weighs no more than a conventional engine, transmission and full gas tank.

|

Thx Ecky! Mazda is posing some very good questions there! Worth thinking about!

While electricity isnt nearly as clean as we like to believe it is, it's cheap... (ATM!!) and enables regen.

So mazda is saying: "As it's hardly used; make it as light and cheap as possible"

That makes sense from the 98% of driving is city where 68% of fuel is used to accelerate weight.

Better yet might be a 'Stay at home 98% of the time, quick connect genset type engine doodat, that one only 'plugs in' when a longer trip is planned, saving that weight.

The problem there is one can never underestimate the ingenious ways in which idiots manage to uck this sort of thing fup!

The other way to go may be an even smaller than 'required freeway cruise power' sized, always-on engine:

That's lighter, takes lifespan killing amp load of a smaller lighter battery all the time and provides heat for the interior.

That, combined with regen, should work fine in town.

During the normal bathroom/fuel/food stops of a long trip; the engine stays on at it's optimized rpm, charging away, so you don't (normally) run out of battery.

Add the option to also plug it into an EV charger (if there is one) if you like.

Then there's also all that, easy at constant rpm, fuel pyrolysis/ Steam Reformation/ Water Gas Shift reaction stuff one might do.

As the power is more off than on here in The New South Africa; having a genset wherever I am is another big selling point.

Last edited by Logic; 03-22-2025 at 09:29 AM..

|

|

|

|

|

The Following User Says Thank You to Logic For This Useful Post:

|

|

03-18-2025, 12:40 PM

03-18-2025, 12:40 PM

|

#6 (permalink)

|

|

Master EcoModder

Join Date: Dec 2011

Location: New Zealand

Posts: 5,142

Thanks: 2,930

Thanked 2,603 Times in 1,619 Posts

|

It's definitely a point that different places in the world have different needs and different use cases. North America has the challenge of extreme cold and long driving distances. Some places have clean grids and others are less so. Fuel is also very cheap, while electricity is often not (though it is reliable).

Where I live now, the grid is around 85% "clean" and getting cleaner (I'm not denying hydro and wind don't have downsides) with low electricity prices and high fuel costs, and the weather is always mild, so what works well here may not be ideal in other areas.

The downsized genset is definitely a point, and something I'd consider, as is a removable one, but without intelligent management (route and intention awareness) it's at the mercy of the competence of your average driver. I suppose any idiot-proof system naturally has compromises. Pick your poison.

I wonder what percent of the world's (car owning) population has high levels of electricity insecurity? South Africa's case seems relatively uncommon, though I may simply not be aware of others.

|

|

|

|

|

The Following User Says Thank You to Ecky For This Useful Post:

|

|

03-18-2025, 01:44 PM

03-18-2025, 01:44 PM

|

#7 (permalink)

|

|

Master EcoModder

Join Date: Aug 2012

Location: northwest of normal

Posts: 29,407

Thanks: 8,364

Thanked 9,123 Times in 7,533 Posts

|

Quote:

|

While electricity isnt nearly as clean as we like to believe it is, it's cheap... (ATM!!) and enables regen.

|

Electricity is fungible.

__________________

.

.Without freedom of speech we wouldn't know who all the idiots are. -- anonymous poster

___________________

.

.tragectory: Line goes down and to the right.

|

|

|

|

03-22-2025, 11:40 AM

03-22-2025, 11:40 AM

|

#8 (permalink)

|

|

Master EcoModder

Join Date: Aug 2022

Location: South Africa

Posts: 874

Thanks: 341

Thanked 350 Times in 303 Posts

|

Quote:

Originally Posted by freebeard

Electricity is fungible.

|

Sure, but I'm trying to stick to world averages here, as a means of figuring out what car makers (and co) are thinking, if they are in fact thinking!

Then probably the biggest factor is;

most don't really give a damn where the electricity's coming from.

(as long as it's not a coal plant 'next door', reminding them of just how ...'clean' electricity actually is)

All most really care about is cost.

(But not enough to consider CHP it seems!  ) |

|

|

|

|

The Following User Says Thank You to Logic For This Useful Post:

|

|

03-22-2025, 12:15 PM

03-22-2025, 12:15 PM

|

#9 (permalink)

|

|

Master EcoModder

Join Date: Aug 2022

Location: South Africa

Posts: 874

Thanks: 341

Thanked 350 Times in 303 Posts

|

Quote:

Originally Posted by Ecky

It's definitely a point that different places in the world have different needs and different use cases. North America has the challenge of extreme cold and long driving distances. Some places have clean grids and others are less so. Fuel is also very cheap, while electricity is often not (though it is reliable).

Where I live now, the grid is around 85% "clean" and getting cleaner (I'm not denying hydro and wind don't have downsides) with low electricity prices and high fuel costs, and the weather is always mild, so what works well here may not be ideal in other areas.

|

Yep. In cold places it makes sense to have an ICE as a heater that also produces electricity!

There's battery heating too.

And there's no reason a 'linear motor except for the power stroke' cant do 1 or 2 'rpm' and be off mostly. if all you want is X amount of heat.

Quote:

Originally Posted by Ecky

The downsized genset is definitely a point, and something I'd consider, as is a removable one, but without intelligent management (route and intention awareness) it's at the mercy of the competence of your average driver. I suppose any idiot-proof system naturally has compromises. Pick your poison.

|

Yes; a computer that asks you here you want to go, with choices sorted by where you normally go on a Monday morning at 6.30 for eg.

Something that's GPS etc connected and also logs data for work n back trips, with perhaps plugin while there, etc-etc.

ie; knows about traffic and every route, robot, up n down, etc in the trip.

I believe that would help tremendously and go down well with the public.

Quote:

Originally Posted by Ecky

I wonder what percent of the world's (car owning) population has high levels of electricity insecurity? South Africa's case seems relatively uncommon, though I may simply not be aware of others.

|

Here 'electricity anxiety' is high.. atm

In the rest of Africa it's now largely: "Why be anxious about something that doesn't exist. Hakuna Matata!  "

Last edited by Logic; 03-22-2025 at 01:40 PM..

|

|

|

|

|

The Following User Says Thank You to Logic For This Useful Post:

|

|

03-23-2025, 05:42 PM

03-23-2025, 05:42 PM

|

#10 (permalink)

|

|

Master EcoModder

Join Date: Aug 2012

Location: northwest of normal

Posts: 29,407

Thanks: 8,364

Thanked 9,123 Times in 7,533 Posts

|

Quote:

Something that's GPS etc connected and also logs data for work n back trips, with perhaps plugin while there, etc-etc.

ie; knows about traffic and every route, robot, up n down, etc in the trip.

|

Something from Eugene, OR, that never went anywhere [apparently] I'm A Green Driver/Enlighten

www.govtech.com/transportation/traffic-app-predicts-green-lights.html

Quote:

Traffic App Predicts Green Lights

Ever feel like red lights last forever? A new app tells you how long you'll have to wait to see green.

January 13, 2014 • Jessica Mulholland

A new smartphone app called EnLighten is telling drivers how long they might be waiting at traffic lights. Inventor Matt Ginsberg’s novel creation predicts when a red light will turn green.

The app uses GPS technology to gather location data and analyze traffic information. It can also calculate a car’s velocity using its accelerometer. In many cities, traffic light timing changes depending on real-time traffic, so the app generates a prediction based on a combination of factors.

Ginsberg’s goal is to have the app running in 50 cities by year’s end. So far, Portland and Eugene, Ore.; Pasadena, Arcadia and San Jose, Calif.; Salt Lake City and Provo, Utah; Garland, Texas; and Las Vegas, Nev., are on board.

|

I experienced this once when my son was in town with his SRT-8 and iPhone.

Anyways... what I came here to say was -- on topic or not?

The 'revolutonary design' is lifted from the steam compound engine. But note especially at ?t=592 the Isothermal Compressed-Air Vehicle. They claim 90% of battery performance levels.

My interest in compressed air comes from the Scuderi patent. It's a split-cycle arrangement that can have a compressed air tank interposed to make an internal combustion/compressed air hybrid.

I suspect a flat four boxer could salvage that tech. An inline two-cylinder ICE on one bank and a compressor on the other with different sized cylinders.

__________________

.

.Without freedom of speech we wouldn't know who all the idiots are. -- anonymous poster

___________________

.

.tragectory: Line goes down and to the right.

|

|

|

|

|