06-19-2022, 10:53 AM

06-19-2022, 10:53 AM

|

#361 (permalink)

|

|

Master EcoModder

Join Date: Aug 2012

Location: northwest of normal

Posts: 29,296

Thanks: 8,333

Thanked 9,092 Times in 7,509 Posts

|

A shear/brake/roller is a standard sheet metal tool, but a 60" throat would be exceptional. Lay two pipes on the ground, center the material and press a third pipe down on the line of the bend. It would act as a brake but without the sharp angle.

Compound curve is another matter. Either heat or explosive forming would be necessary.

__________________

.

.Without freedom of speech we wouldn't know who all the idiots are. -- anonymous poster

___________________

.

.Impossible is just something we haven't done yet. -- Langley Outdoors Academy

|

|

|

|

Today Today

|

|

|

|

Other popular topics in this forum...

Other popular topics in this forum...

|

|

|

|

06-19-2022, 02:29 PM

06-19-2022, 02:29 PM

|

#362 (permalink)

|

|

Master EcoModder

Join Date: Mar 2022

Location: oregon

Posts: 1,123

Thanks: 1

Thanked 595 Times in 472 Posts

|

Quote:

Originally Posted by freebeard

A shear/brake/roller is a standard sheet metal tool, but a 60" throat would be exceptional. Lay two pipes on the ground, center the material and press a third pipe down on the line of the bend. It would act as a brake but without the sharp angle.

Compound curve is another matter. Either heat or explosive forming would be necessary. |

I’d only need to curve the last 2 feet or so after the muffler though. I’d have the 60 inches going straight mostly, then just curve the last section to the bumper

Seems like the rear wheel spats will be tricky too because of the more rounded 3D shape. Hopefully the dibond isn’t too freakishly stiff like steel. The normal thin aluminum sheets were waaay too wobbly

I really hope I’m not getting too far in over my head on this |

|

|

|

06-19-2022, 03:34 PM

06-19-2022, 03:34 PM

|

#363 (permalink)

|

|

Master EcoModder

Join Date: Aug 2012

Location: northwest of normal

Posts: 29,296

Thanks: 8,333

Thanked 9,092 Times in 7,509 Posts

|

I looked up duckduckgo.com/?q=dibond+aluminum+sheet. It's what I've known as Polymetal. Both are brand names.

Heat is right out. Explosive forming could work. Do you have a swimming pool?

Were it I, I'd prolly go for a low-poly faceted construction. It's less complex than this example:

Maybe one long dart to make a cone off-centered to the front and 2 or 3 at the rear to make a tearing edge/skeg. Lapping the seam might be possible, I've not had success with my experiments. a 3mm H-channel is another option.

My experiments:

Braking the flanges ruptured the outer skin. Scoring on the inside first might prevent that. I don't know about scoring dibond.

__________________

.

.Without freedom of speech we wouldn't know who all the idiots are. -- anonymous poster

___________________

.

.Impossible is just something we haven't done yet. -- Langley Outdoors Academy

|

|

|

|

06-19-2022, 05:57 PM

06-19-2022, 05:57 PM

|

#364 (permalink)

|

|

Master EcoModder

Join Date: Mar 2022

Location: oregon

Posts: 1,123

Thanks: 1

Thanked 595 Times in 472 Posts

|

Quote:

Originally Posted by freebeard

I looked up duckduckgo.com/?q=dibond+aluminum+sheet. It's what I've known as Polymetal. Both are brand names.

Heat is right out. Explosive forming could work. Do you have a swimming pool?

Were it I, I'd prolly go for a low-poly faceted construction. It's less complex than this example:

Maybe one long dart to make a cone off-centered to the front and 2 or 3 at the rear to make a tearing edge/skeg. Lapping the seam might be possible, I've not had success with my experiments. a 3mm H-channel is another option.

My experiments:

Braking the flanges ruptured the outer skin. Scoring on the inside first might prevent that. I don't know about scoring dibond. |

nope dont have any of that. are you saying i wont be able to bend the sheets i bought? should i get a refund or something?

normal aluminum is too floppy and you can just pinch to bend. i was hoping these would be a little stiffer like cardboard, but not too ultra stiff

|

|

|

|

06-19-2022, 06:51 PM

06-19-2022, 06:51 PM

|

#365 (permalink)

|

|

Master EcoModder

Join Date: Aug 2012

Location: northwest of normal

Posts: 29,296

Thanks: 8,333

Thanked 9,092 Times in 7,509 Posts

|

Do or do not, there is no try?

You can see the extent of my experience. Sheared, barked and rollered on a [bench-mount] hand tool with an 18" throat.

It's really stiff. The core is thermoplastic so you might be able to slump-mound it, but the finished skin is fragile so that mitigates against English wheels or hammer and shot bag.

An edge roller is a possibility. And artistic corrugations to crimp the trailing edge.

__________________

.

.Without freedom of speech we wouldn't know who all the idiots are. -- anonymous poster

___________________

.

.Impossible is just something we haven't done yet. -- Langley Outdoors Academy

|

|

|

|

06-19-2022, 06:59 PM

06-19-2022, 06:59 PM

|

#366 (permalink)

|

|

Master EcoModder

Join Date: Aug 2012

Location: northwest of normal

Posts: 29,296

Thanks: 8,333

Thanked 9,092 Times in 7,509 Posts

|

That might be an interesting science experiment, take a two foot tall, three foot diameter watering trough or just a ring, bury it in the ground,fill it to the brim with water, clamp the sheet and set off a blasting cap or M-80 in the water.

In a perfect world you could use the weight holding down the blank as a relief valve, adding or removing weight to regulate the curvature.

__________________

.

.Without freedom of speech we wouldn't know who all the idiots are. -- anonymous poster

___________________

.

.Impossible is just something we haven't done yet. -- Langley Outdoors Academy

|

|

|

|

06-19-2022, 07:39 PM

06-19-2022, 07:39 PM

|

#367 (permalink)

|

|

Master EcoModder

Join Date: Mar 2022

Location: oregon

Posts: 1,123

Thanks: 1

Thanked 595 Times in 472 Posts

|

Quote:

Originally Posted by freebeard

Do or do not, there is no try?

You can see the extent of my experience. Sheared, barked and rollered on a [bench-mount] hand tool with an 18" throat.

It's really stiff. The core is thermoplastic so you might be able to slump-mound it, but the finished skin is fragile so that mitigates against English wheels or hammer and shot bag.

An edge roller is a possibility. And artistic corrugations to crimp the trailing edge.

|

and youre using the exact same material?

https://www.homedepot.com/p/Falken-D...3636/308670301 |

|

|

|

06-20-2022, 01:20 AM

06-20-2022, 01:20 AM

|

#368 (permalink)

|

|

Master EcoModder

Join Date: Aug 2012

Location: northwest of normal

Posts: 29,296

Thanks: 8,333

Thanked 9,092 Times in 7,509 Posts

|

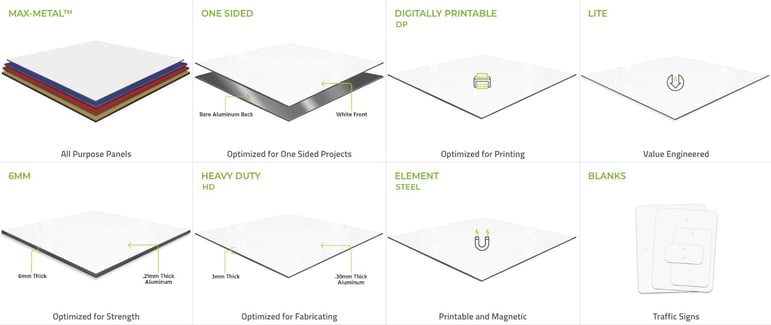

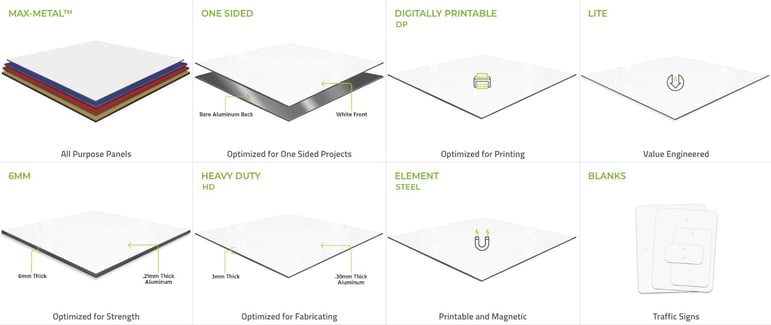

https://nudo.com/p_polymetal.php Similar. 3mm thermoplastic with 0.17" skins and baked enamel finish.

Another product is Grimco Maxmetal. connect.grimco.com/blog/maxmetal-meet-the-brand

They have Light, 6mm and heavy Duty variants, and single sided. I haven't seen their product, just the website.

You might form a single-sided sheet and then fiberglass the inner surface and fixtures where the finish doesn't count

__________________

.

.Without freedom of speech we wouldn't know who all the idiots are. -- anonymous poster

___________________

.

.Impossible is just something we haven't done yet. -- Langley Outdoors Academy

|

|

|

|

06-20-2022, 09:36 PM

06-20-2022, 09:36 PM

|

#369 (permalink)

|

|

Master EcoModder

Join Date: Mar 2022

Location: oregon

Posts: 1,123

Thanks: 1

Thanked 595 Times in 472 Posts

|

Quote:

Originally Posted by freebeard

https://nudo.com/p_polymetal.php Similar. 3mm thermoplastic with 0.17" skins and baked enamel finish.

Another product is Grimco Maxmetal. connect.grimco.com/blog/maxmetal-meet-the-brand

They have Light, 6mm and heavy Duty variants, and single sided. I haven't seen their product, just the website.

You might form a single-sided sheet and then fiberglass the inner surface and fixtures where the finish doesn't count

|

i actually got a dibond sample frpm sign shop/ stiffer than thin aluminum but super wobbly and flimsy actually. cardboard and coroplast is actually stiffer!

heck for the underbody im probably going to need to bolt a lot of fasteners into place and possibly weld some stiffening rods into it...

|

|

|

|

06-20-2022, 11:01 PM

06-20-2022, 11:01 PM

|

#370 (permalink)

|

|

Master EcoModder

Join Date: Aug 2012

Location: northwest of normal

Posts: 29,296

Thanks: 8,333

Thanked 9,092 Times in 7,509 Posts

|

When the subject of reinforcing Coroplast came up, I proposed this:

Rods through the flutes of course, but edging that's either left exposed and taped, or covered with flaps wrapped over it.

__________________

.

.Without freedom of speech we wouldn't know who all the idiots are. -- anonymous poster

___________________

.

.Impossible is just something we haven't done yet. -- Langley Outdoors Academy

|

|

|

|

|