10-20-2009, 08:08 AM

10-20-2009, 08:08 AM

|

#1 (permalink)

|

|

EcoModding Lurker

Join Date: Oct 2009

Location: canada

Posts: 7

Thanks: 0

Thanked 0 Times in 0 Posts

|

Need Confirmation

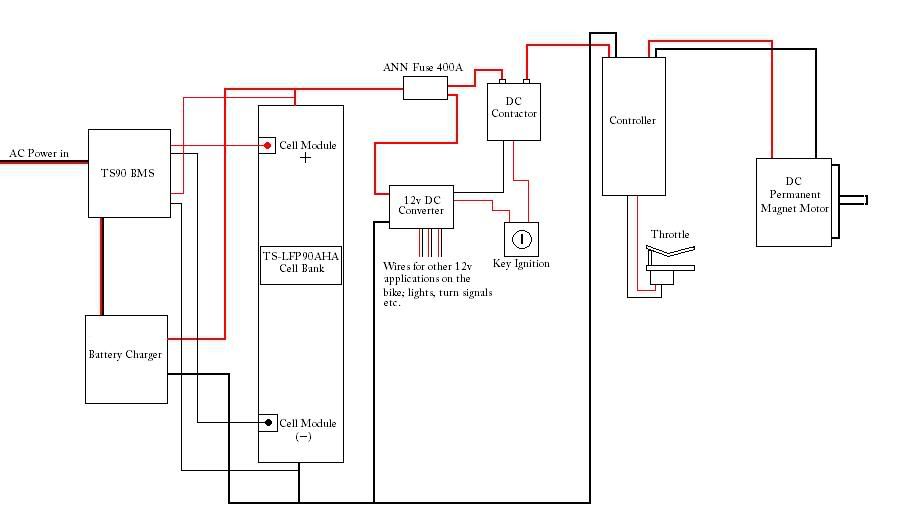

so im in the planning stages of building an electric motorcycle, and after lots of researching and web searching, i have been able to draw up this wiring diagram based on what i've learned. if a few experienced converters could look at it and tell me what they think that'd be great

|

|

|

|

Today Today

|

|

|

|

Other popular topics in this forum...

Other popular topics in this forum...

|

|

|

|

10-20-2009, 08:32 AM

10-20-2009, 08:32 AM

|

#2 (permalink)

|

|

Administrator

Join Date: Dec 2007

Location: Germantown, WI

Posts: 11,203

Thanks: 2,501

Thanked 2,589 Times in 1,555 Posts

|

I'd put the DC to DC on its own fuse from the battery. That will help in preventing it from burning out.

I'm also not sure what the TS90 is, but why are there two wires going from it to the + and -?

The rest looks good to me.

|

|

|

|

10-20-2009, 08:37 AM

10-20-2009, 08:37 AM

|

#3 (permalink)

|

|

EcoModding Lurker

Join Date: Oct 2009

Location: canada

Posts: 7

Thanks: 0

Thanked 0 Times in 0 Posts

|

the TS90 is a battery management system from here:

EV Works Pty Ltd

and the 2 wires just represent both ends of the module chain, the other 2 power the master unit. modules here:

EV Works Pty Ltd

btw, you think i should use a smaller fuse?? |

|

|

|

10-20-2009, 09:53 AM

10-20-2009, 09:53 AM

|

#4 (permalink)

|

|

Administrator

Join Date: Dec 2007

Location: Germantown, WI

Posts: 11,203

Thanks: 2,501

Thanked 2,589 Times in 1,555 Posts

|

I think you shouldn't run the dc to dc converter through your 400A fuse. Wire the dc to dc converter to the batteries with its own fuse that is rated just over what the converter will pull. I just used 50A as an example.

Like this:

|

|

|

|

10-20-2009, 11:00 AM

10-20-2009, 11:00 AM

|

#5 (permalink)

|

|

EcoModding Lurker

Join Date: Oct 2009

Location: canada

Posts: 7

Thanks: 0

Thanked 0 Times in 0 Posts

|

you know thats actually kinda scary, cuz after i read your post i went to revise my diagram, and my revision looks almost exactly the same as yours. Spooky!!! lol. anyway, with my conversion im more concerned with range than speed. i want it to be able to go at least 90 kh/h, which is pretty standard i think, but i want at least the same in range. now if my understanding is correct, the lower the current is with an appropriate amount of cells attached, the farther you can travel on a single charge. Simply put higher voltage equals higher speed, coupled with lower current equals longer range. am i right about that, or does it work a different way??

|

|

|

|

10-20-2009, 01:26 PM

10-20-2009, 01:26 PM

|

#6 (permalink)

|

|

eco....something or other

Join Date: Jul 2009

Location: Colfax, WI

Posts: 724

Thanks: 39

Thanked 67 Times in 50 Posts

|

I think that's right

From my forklift mechanic days...they ran on 48 volt batteries that were BIG, 2,500 LBS big. On take-off you would use roughly 500 amps and cruising was more like 60amps depending on how you set the cards. Of course you could turn down the max amps and get a little more distance, but you couldn't go up a ramp very well. I used to set them to 550 top end and they would fly right up a ramp. (then you have gearing too, I doubt your car will weigh 4 or 5 tons.) The cards had pots on them and controlled the speed/pedel/current relationships. Turns out I was the only one that actually adjusted the cards, and extended battery life and component life by doing so. Most of the other guys just replaced a burned out card and sent the lift out, only to have the card burn out in a week. However you are setting up the system, make sure you stay below the max current and voltage capacities for the components used. If using an analog setup, be sure to adjust all your pots, etc accordingly. I LOVE analog because it is in your hands, not the computer's,LOL. HAVE FUN

(I miss being able to lug around 25,000LBS with a B50)

__________________

1991 F-250:

4.9L, Mazda 5 speed, 4.10 10.25" rear

|

|

|

|

10-20-2009, 01:47 PM

10-20-2009, 01:47 PM

|

#7 (permalink)

|

|

Administrator

Join Date: Dec 2007

Location: Germantown, WI

Posts: 11,203

Thanks: 2,501

Thanked 2,589 Times in 1,555 Posts

|

You want to be able to go 90km (55 miles)? That is really pushing it unless you go with a pretty large bike. However, I see your management system is for a lithium battery pack. This should allow you to pack enough batteries to get the range you desire. I would estimate that the motorcycle will use 250Wh/mile. Since you want to go 55 miles, you need at least a 14 kWh pack, preferably a 28 kWh pack to keep your depth of discharge up and extend battery life.

Since you are going with such a large pack, I'd go with as high of a voltage as you can to keep the amperage down.

|

|

|

|

10-20-2009, 02:45 PM

10-20-2009, 02:45 PM

|

#8 (permalink)

|

|

EcoModding Apprentice

Join Date: May 2008

Location: N. Saskatchewan, CA

Posts: 1,805

Thanks: 91

Thanked 460 Times in 328 Posts

|

Range

Quote:

Originally Posted by angelarm1110

you know thats actually kinda scary, cuz after i read your post i went to revise my diagram, and my revision looks almost exactly the same as yours. Spooky!!! lol. anyway, with my conversion im more concerned with range than speed. i want it to be able to go at least 90 kh/h, which is pretty standard i think, but i want at least the same in range. now if my understanding is correct, the lower the current is with an appropriate amount of cells attached, the farther you can travel on a single charge. Simply put higher voltage equals higher speed, coupled with lower current equals longer range. am i right about that, or does it work a different way??

|

There's no free lunch, or everything would be run at super-high voltages. If you set a pack up for higher voltage, the amperage goes down. The available watt-hours remain the same, but higher speeds use them up faster, so range goes down more than travel time. |

|

|

|

10-20-2009, 04:42 PM

10-20-2009, 04:42 PM

|

#9 (permalink)

|

|

Misanthropologist

Join Date: Sep 2008

Location: Sterling, VA

Posts: 383

BORK! - '89 Volvo 240 DL Wagon 90 day: 21.27 mpg (US)

Thanks: 2

Thanked 24 Times in 13 Posts

|

If your DC converter isn't powering very much you should be putting the ignition between the battery pack and it. Unless of course the DC converter itself has its own On/Off pins that you could wire the ignition to.

As your system is laid out now everything connected to the DC converter would be on all the time.

My wiring schematic became pretty detailed long before I even started working on the wiring.

Last edited by captainslug; 10-20-2009 at 04:48 PM..

|

|

|

|

10-20-2009, 04:52 PM

10-20-2009, 04:52 PM

|

#10 (permalink)

|

|

EcoModding Lurker

Join Date: Oct 2009

Location: canada

Posts: 7

Thanks: 0

Thanked 0 Times in 0 Posts

|

my understanding was that if there was no load on any of the 12 volt applications, then the converter wouldn't be drawing any power from the cells, however if that is not the case (which now that i think about it, probably isn't), then perhaps i should make sure to find one with on/off pins like you said, and wire that to a switch on the handle bars or something.

|

|

|

|

|