01-11-2015, 07:25 PM

01-11-2015, 07:25 PM

|

#1561 (permalink)

|

|

Master EcoModder

Join Date: Oct 2012

Location: USA

Posts: 1,408

Thanks: 102

Thanked 252 Times in 204 Posts

|

2 of the ES55242-140M-200AV might work interleaved @ 20khz per inductor to make 70A@510v combined from 144v, not real sure how to compute inductor losses though. Just resistive would be about 12watts apiece, 215 peak inductor current, avg ~107 (triangular). 1.1mOhm.

reduce the duty cycle or the load or the frequency and it gets discontinuous (though the inductor is ramping from ~0-215A as it is). Though I realize I'm proposing %100 current ripple here, so gonna be some AC losses...

Last edited by P-hack; 01-11-2015 at 08:21 PM..

|

|

|

|

|

The Following User Says Thank You to P-hack For This Useful Post:

|

|

Today Today

|

|

|

|

Other popular topics in this forum...

Other popular topics in this forum...

|

|

|

|

01-11-2015, 09:09 PM

01-11-2015, 09:09 PM

|

#1562 (permalink)

|

|

EcoModding Apprentice

Join Date: Nov 2012

Location: East Midlands

Posts: 180

Thanks: 13

Thanked 81 Times in 52 Posts

|

Quote:

Originally Posted by P-hack

2 of the ES55242-140M-200AV might work interleaved @ 20khz per inductor to make 70A@510v combined from 144v, not real sure how to compute inductor losses though. Just resistive would be about 12watts apiece, 215 peak inductor current, avg ~107 (triangular). 1.1mOhm.

reduce the duty cycle or the load or the frequency and it gets discontinuous (though the inductor is ramping from ~0-215A as it is). Though I realize I'm proposing %100 current ripple here, so gonna be some AC losses...

|

Ive been doing some calculations using the micrometals simulator.

http://www.micrometals.com/downloads..._March2010.exe

Ripple translates to very high core losses. They go down with frequency (100KHz++). To reduce them one could increase the inductance, but that would increase copper losses. Add to that that the inductance itself goes down very quickly at high currents and this might be a harder challenge than originally envisioned. |

|

|

|

01-11-2015, 10:02 PM

01-11-2015, 10:02 PM

|

#1563 (permalink)

|

|

PaulH

Join Date: Feb 2008

Location: Maricopa, AZ (sort of. Actually outside of town)

Posts: 3,832

Thanks: 1,362

Thanked 1,202 Times in 765 Posts

|

On their calculator, what do they mean by the inductor on and off voltage? If input voltage was 200, and output was 600, would I use those 2 values?

edit: I guess inductor ON voltage would be the pack voltage. And off voltage would be the voltage across the inductor while the switch is off? How awkward.

I was looking at some SiC half bridges on Mouser. They had a 300amp 1200v 5mOhm RdsON mosfet half bridge, but it was expensive, and the switching losses weren't small. They had 200KHz listed as a sample switching frequency, but then looking at the losses when it was an inductive load, each switch would have about 1500w of waste heat. And the peak power dissipation was 1600w.

The CH-200 I bought awhile back is under $300 in quantity 10. Maybe that is good enough. 200amp continuous

Last edited by MPaulHolmes; 01-11-2015 at 10:59 PM..

|

|

|

|

01-11-2015, 11:47 PM

01-11-2015, 11:47 PM

|

#1564 (permalink)

|

|

EcoModding Apprentice

Join Date: Nov 2012

Location: East Midlands

Posts: 180

Thanks: 13

Thanked 81 Times in 52 Posts

|

Quote:

Originally Posted by MPaulHolmes

On their calculator, what do they mean by the inductor on and off voltage? If input voltage was 200, and output was 600, would I use those 2 values?

edit: I guess inductor ON voltage would be the pack voltage. And off voltage would be the voltage across the inductor while the switch is off? How awkward.

I was looking at some SiC half bridges on Mouser. They had a 300amp 1200v 5mOhm RdsON mosfet half bridge, but it was expensive, and the switching losses weren't small. They had 200KHz listed as a sample switching frequency, but then looking at the losses when it was an inductive load, each switch would have about 1500w of waste heat. And the peak power dissipation was 1600w.

The CH-200 I bought awhile back is under $300 in quantity 10. Maybe that is good enough. 200amp continuous

|

I am using the PFC calculations. Which one are you using?

Just make sure the maximun input voltage is in AC, so for DC divide by 1.41 (144V ~ 100VAC).

Those values for the mosfet seem correct. I'm assuming they tested at 600V with a 100A load or something. Whats the RDS(on)? IGBT is probably best in terms on conduction losses at high currents, but switching losses are a bit higher as it is slower.

So, we have conduction losses and switching losses:

Assume 200Amps for the inductor

PD(conduction) = VCE/VGE(sat)*Io*Duty(on)

So for a 200A and a voltage drop of 1.7(assumed) and a duty = 50% that would be 170W

Now switching, depends on the frequency and the RDS(on)

PD(sw) = (Vd*Io*F(sw)*(t_rise+Tfall))/2

PD(sw) = (144*200*20KHz*200ns)/2

PD(sw) = 28.8W

here I'm assuming a rise and fall time of 200ns

At 200Khz, that jumps to 280watt! But the resistive and core losses on the inductor probably will go down twice as much.

Last edited by cts_casemod; 01-11-2015 at 11:57 PM..

|

|

|

|

01-12-2015, 12:00 AM

01-12-2015, 12:00 AM

|

#1565 (permalink)

|

|

EcoModding Apprentice

Join Date: Nov 2012

Location: East Midlands

Posts: 180

Thanks: 13

Thanked 81 Times in 52 Posts

|

Bad news. I tried to get the inductor on the link I posted earlier, but the minimum postage option to the UK was $65. Add to that another much on customs!

If anyone's thinking in buying and can post me one let me know. It surelly turns out cheaper. I can paypal the payment or something!

Also related is the option to wire my own. I have been looking at the T600-52 core from micrometals. But the problem is getting some litz wire. Cheapest I found (AWG10) was $100 for 30ft!

Paul, that flat copper sheet you were going to use to for the E cores, have you found a supplier for it?

|

|

|

|

01-12-2015, 05:21 AM

01-12-2015, 05:21 AM

|

#1566 (permalink)

|

|

EcoModding Lurker

Join Date: Dec 2011

Location: Poland

Posts: 66

Thanks: 12

Thanked 27 Times in 22 Posts

|

Hi cts, you might want to check this supplier in Poland: Feryster

Mike |

|

|

|

|

The Following 2 Users Say Thank You to z_power For This Useful Post:

|

|

01-12-2015, 08:20 AM

01-12-2015, 08:20 AM

|

#1567 (permalink)

|

|

Master EcoModder

Join Date: Oct 2012

Location: USA

Posts: 1,408

Thanks: 102

Thanked 252 Times in 204 Posts

|

despite it's resemblance to a certain motor controller, at the multi-hundred dollar price point it is probably worth revisiting multiple high voltage mosfets @100khz, perhaps each with its own inductor and diode but one significant gate driver (or interleaved for $$). But getting the switches/inductors down to the 60 amp range could be good for costs.

Also it seems like litz would need a certain length to be effective, don't know, but plain old 28 strands of 26 gauge seems doable on a nailboard.

|

|

|

|

01-12-2015, 10:51 AM

01-12-2015, 10:51 AM

|

#1569 (permalink)

|

|

PaulH

Join Date: Feb 2008

Location: Maricopa, AZ (sort of. Actually outside of town)

Posts: 3,832

Thanks: 1,362

Thanked 1,202 Times in 765 Posts

|

For copper sheet, there's basiccopper.com, and nimrodcopper.com. They both have 6" x 0.020" x VERY_LONG. The E827 part is a little over 7" wide, which would be perfect for a 6" copper sheet.

|

|

|

|

01-12-2015, 11:27 AM

01-12-2015, 11:27 AM

|

#1570 (permalink)

|

|

PaulH

Join Date: Feb 2008

Location: Maricopa, AZ (sort of. Actually outside of town)

Posts: 3,832

Thanks: 1,362

Thanked 1,202 Times in 765 Posts

|

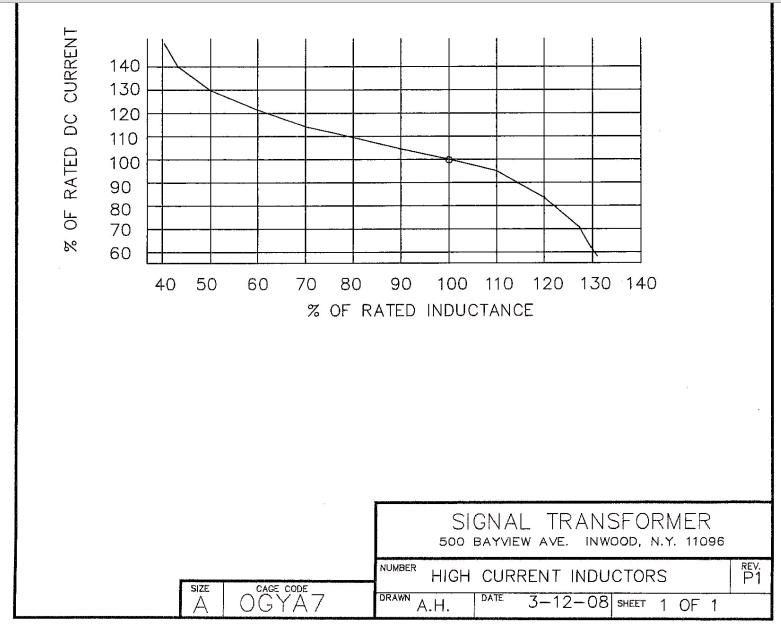

I just talked to Signal Transformer, and they sent me a graph of the CH-200 inductance vs. current graph.

I have used it 24/7 at 10KHz (even at night it's trying to track max power. talk about lazy programming on my part!) over the last couple years in a maximum power point tracker, running at about 90 amps during the peak sun hours of the day, in a shop that gets over 120degF. Not a dent in the fender! haha.

Notice the graph shows that the inductance is still 120uH at 300amp input.

|

|

|

|

|