10-07-2023, 12:43 PM

10-07-2023, 12:43 PM

|

#41 (permalink)

|

|

Master EcoModder

Join Date: Dec 2016

Location: Florida

Posts: 390

Thanks: 64

Thanked 163 Times in 138 Posts

|

On a top fuel dragster, a similar video in Slow mo indicates individual cylinder pulses as each cylinder fires in the area of a 1000hp? each, very impressive.

My assumption is the wrinkle wall helps cushion those impulses to help maintain traction.

|

|

|

|

|

The Following User Says Thank You to j-c-c For This Useful Post:

|

|

Today Today

|

|

|

|

Other popular topics in this forum...

Other popular topics in this forum...

|

|

|

|

10-08-2023, 07:10 AM

10-08-2023, 07:10 AM

|

#42 (permalink)

|

|

Tire Geek

Join Date: May 2008

Location: Let's just say I'm in the US

Posts: 794

Thanks: 4

Thanked 388 Times in 237 Posts

|

Quote:

Originally Posted by Isaac Zachary

It doesn't sound like what I've always understood.

Why would the coefficient change as you drive? From what I've always understood it stays about the same.

UNLESS we are talking about power to overcome rolling resistance. That does increase with the square of the velocity.

But the force to overcome rolling resistance should be about the same. The amount of energy per measure of distance will be about the same.

The power increases because the faster you go the more energy per measure of distance gets eaten up quicker as you travel more distance per measure of time.

|

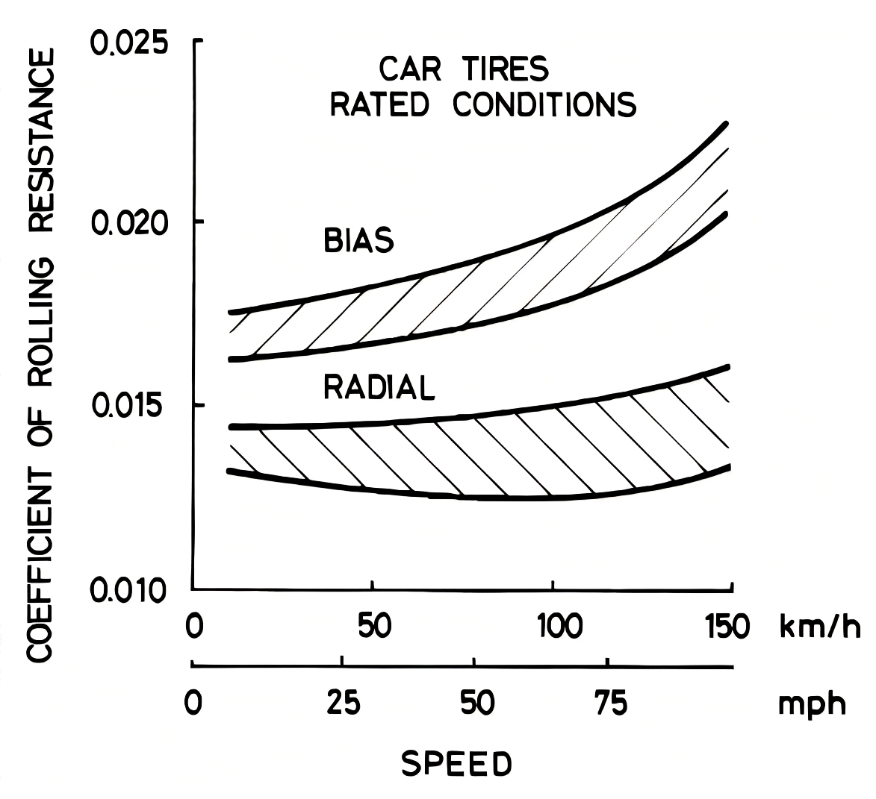

The explanation for the increase in RR vs speed is that a rolling tire generates a standing wave in the tire - which consumes energy. The faster the speed, the larger the wave and the more energy it consumes.

Edit: There are images for graphs showing RR vs speed. They don't seem to be showing up. Here are links:

http://barrystiretech.com/rrvsspeed.png

http://barrystiretech.com/truckrrvsspeed.gif

Last edited by CapriRacer; 10-08-2023 at 07:18 AM..

|

|

|

|

|

The Following User Says Thank You to CapriRacer For This Useful Post:

|

|

10-09-2023, 12:18 PM

10-09-2023, 12:18 PM

|

#43 (permalink)

|

|

Master EcoModder

Join Date: Jan 2008

Location: Sanger,Texas,U.S.A.

Posts: 15,895

Thanks: 23,972

Thanked 7,223 Times in 4,650 Posts

|

some old metrics from Pirelli

Long ago and far away, CAR and DRIVER did a pretty big piece on tire tech, citing data shared by Pirelli Tire Co..

Rolling resistance would be be affected by:

* pressure

* velocity

* load

* traction rating

* rubber hysteresis

* sidewall flexure

* number of plies

* diameter

* slip angle

* tread width

* rim ( wheel ) width

* tread-block transverse hinging

* tread design

* sidewall aspect ratio

* Ply construction

* contact patch lengthening in proportion to load.

* contact patch lengthening as an inverse proportion to the square root of the inflation pressure.

* R-R proportional to the product of the mean ground contact pressure and the distance of the center of pressure from the geometrical center of the contact area.

*presence of longitudinal ribs or not ( 'quiet bands' ).

* ambient temperature.

* 70-degrees F is considered 'COLD.'

* LRR is structurally limited to a degree, due to EPA regulated noise criteria, which limits a weighted sound pressure level tires can legally generate while on public roadways.

__________________

Photobucket album: http://s1271.photobucket.com/albums/jj622/aerohead2/

|

|

|

|

10-12-2023, 04:42 PM

10-12-2023, 04:42 PM

|

#44 (permalink)

|

|

Master EcoModder

Join Date: Feb 2014

Location: Missoula, MT

Posts: 2,653

Thanks: 301

Thanked 1,178 Times in 807 Posts

|

Quote:

Originally Posted by j-c-c

On a top fuel dragster, a similar video in Slow mo indicates individual cylinder pulses as each cylinder fires in the area of a 1000hp? each, very impressive.

My assumption is the wrinkle wall helps cushion those impulses to help maintain traction.

|

The wrinkle wall may do that, but where it really helps is it squats, then grows. So basically the whole tire is trying to go up which means it's actually pushing down on the track.

This is why places like Engineering Explained are wrong when they talk about quickest possible 0-60 numbers based on how fast the car can decelerate. They try to qualify it with "on street tires" but there are street legal tires that also do this but to a lesser degree. Why the new Demon 170 can beat his "quickest possible" even if you did take rollout off. 1.83 seconds without, 1.66 with. That's on street legal factory equipped tires. Who needs AWD when the front tires aren't even on the ground? |

|

|

|

10-12-2023, 05:54 PM

10-12-2023, 05:54 PM

|

#45 (permalink)

|

|

Master EcoModder

Join Date: Dec 2016

Location: Florida

Posts: 390

Thanks: 64

Thanked 163 Times in 138 Posts

|

[QUOTE=Hersbird;688561]The wrinkle wall may do that, but where it really helps is it squats, then grows. So basically the whole tire is trying to go up which means it's actually pushing down on the track.

You can see in the previous video the chassis push(?) down on the tire, likely just from weight transfer alone during acceleration with a COG above the ground plane, or the suspension is designed to settle, not likely. Notice the distance the axle center loses relative to the bodywork.

I am not certain what positives are actually in play regarding a compressed/wrinkled tire affords in having a reduced rolling radius upon launch. I am fully aware of the advantages of at the end of the run of having a larger rolling radius as any tire grows, but also loses some contact patch/traction with that growth.

This is why places like Engineering Explained are wrong when they talk about quickest possible 0-60 numbers based on how fast the car can decelerate. They try to qualify it with "on street tires" but there are street legal tires that also do this but to a lesser degree. I have no idea what point you are making and hence no comment Why the new Demon 170 can beat his "quickest possible" even if you did take rollout off. 1.83 seconds without, 1.66 with. That's on street legal factory equipped tires. Who needs AWD when the front tires aren't even on the ground? AWD is a plus always because tires exert the most traction per pound ( ie it's not 1 to 1 gain) with lighter loads, and AWD helps achieve that whenever tire sizes are restricted, and 100% weight transfer is not preferable or obtainable (steering by independent rear brakes or not enought HP, etc[/QUOTE]

|

|

|

|

|

The Following User Says Thank You to j-c-c For This Useful Post:

|

|

10-12-2023, 07:13 PM

10-12-2023, 07:13 PM

|

#46 (permalink)

|

|

High Altitude Hybrid

Join Date: Dec 2020

Location: Gunnison, CO

Posts: 1,986

Thanks: 1,056

Thanked 545 Times in 436 Posts

|

Logically, if the car has the same kind of tires both front and rear and has close to a 50/50 weight distribution, any flexing, wrinkling or such will happen both during acceleration and during braking.

I'm sure a top fuel rail dragster is not similar to a typical car we drive down streets.

I also do not see how tire torque causes it to push down. If I let the air out of my tires and my axle is lower, is it pushing down harder on the tires now?

__________________

|

|

|

|

10-12-2023, 09:40 PM

10-12-2023, 09:40 PM

|

#47 (permalink)

|

|

Master EcoModder

Join Date: Aug 2012

Location: northwest of normal

Posts: 27,716

Thanks: 7,781

Thanked 8,586 Times in 7,070 Posts

|

Admittedly an edge case, but is does show the hysterisis.

The picture I wanted to find, and failed, is of a top fuel dragster heating up the tires so It's not even rolling. The rear end bobs up and down similar to a cat about to pounce. They grow 3-4 inches before what you did see.

__________________

.

.Without freedom of speech we wouldn't know who all the idiots are. -- anonymous poster

____________________

.

."We're deeply sorry." -- Pfizer

|

|

|

|

10-12-2023, 10:52 PM

10-12-2023, 10:52 PM

|

#48 (permalink)

|

|

Master EcoModder

Join Date: Dec 2016

Location: Florida

Posts: 390

Thanks: 64

Thanked 163 Times in 138 Posts

|

Quote:

Originally Posted by Isaac Zachary

Logically, if the car has the same kind of tires both front and rear and has close to a 50/50 weight distribution, any flexing, wrinkling or such will happen both during acceleration and during braking.

I'm sure a top fuel rail dragster is not similar to a typical car we drive down streets.

I also do not see how tire torque causes it to push down. If I let the air out of my tires and my axle is lower, is it pushing down harder on the tires now?

|

The wrinkling seen IMO is a byproduct of the lag of the outermost tread surface "stuck" to the pavement lagging rotationally behind the wheel rim, angling the tire's carcasses reinforcement plies from no longer being perpendicular to the rim as the rim/wheel tries to accelerate its rotation, resisted by the car's mass, and that angling of the ply's without stretching allows the tread/contact surface now to become closer to the rim, effectively shortening the rolling radius of the tire. The inherent compression as tire gets a smaller rolling radius of the contact patch forces the sidewall to wrinkle. |

|

|

|

|

The Following User Says Thank You to j-c-c For This Useful Post:

|

|

10-12-2023, 10:57 PM

10-12-2023, 10:57 PM

|

#49 (permalink)

|

|

Master EcoModder

Join Date: Dec 2016

Location: Florida

Posts: 390

Thanks: 64

Thanked 163 Times in 138 Posts

|

Quote:

Originally Posted by freebeard

Admittedly an edge case, but is does show the hysterisis.

The picture I wanted to find, and failed, is of a top fuel dragster heating up the tires so It's not even rolling. The rear end bobs up and down similar to a cat about to pounce. They grow 3-4 inches before what you did see.

|

Sounds like highly damaging "tire shake", seen for years but not yet well understood, but something highly avoided in racing. A similar condition is seen in heavy braking and its called wheel hop, more of a suspension windup/release issue. |

|

|

|

10-12-2023, 11:05 PM

10-12-2023, 11:05 PM

|

#50 (permalink)

|

|

Master EcoModder

Join Date: Aug 2012

Location: northwest of normal

Posts: 27,716

Thanks: 7,781

Thanked 8,586 Times in 7,070 Posts

|

Edge case. The streatch marks reduce the balloning. Wouldn't happen if the tire don't break loose.

the tire contract, the back end drops a few inches.Back to ecommodderland, If the weight is 50-50 I'd want smaller tires on the front to give some predictable oversteer.

Unfortuneatly, I went from 145/15 to 1665-50/15 and it exhibits snap oversteer. The Notchback had 145s and a 4-wheel algnment and it would do little pirrouttes with the throttle.

j-c-c -- Imagine trying to balance one of those monster tires, to that RPM.

__________________

.

.Without freedom of speech we wouldn't know who all the idiots are. -- anonymous poster

____________________

.

."We're deeply sorry." -- Pfizer

|

|

|

|

|