06-17-2010, 12:50 AM

06-17-2010, 12:50 AM

|

#11 (permalink)

|

|

Master EcoModder

Join Date: Jul 2009

Location: New York

Posts: 513

Thanks: 2

Thanked 101 Times in 74 Posts

|

P0300 is random misfire , find it with exhaust pressure pulses

GM has misfire counters in Enhanced data, there may be misfire counts present that are not high enough to code the system

so , no Code .

you will need a scan tool with Enhanced GM software , a generic scan tool can not view misfire counters .

and - there' s more

intake vacuum at hot idle should be around 20"

and

the needle must be steady smooth with zero flutter , if there is any flutter , your new used engine has a valve sealing problem

and

if there is a local shop that has Emisfire OR AceMisfireDetective

either of those systems can pick a misfire out of the exhaust pressure pulses synced to spark or IGT on any cylinder.

they work by looking for a vacuum pulse in the pressure pulses , if a cylinder did not fire or did not fire as strong as the rest of the cylinders , when the exhaust valve opens at about 150 degrees after TDC , there will be a Lower pressure or vacuum pulse added to the exhaust pulse train .

not too expensive to connect

i charge 1 hour of labor

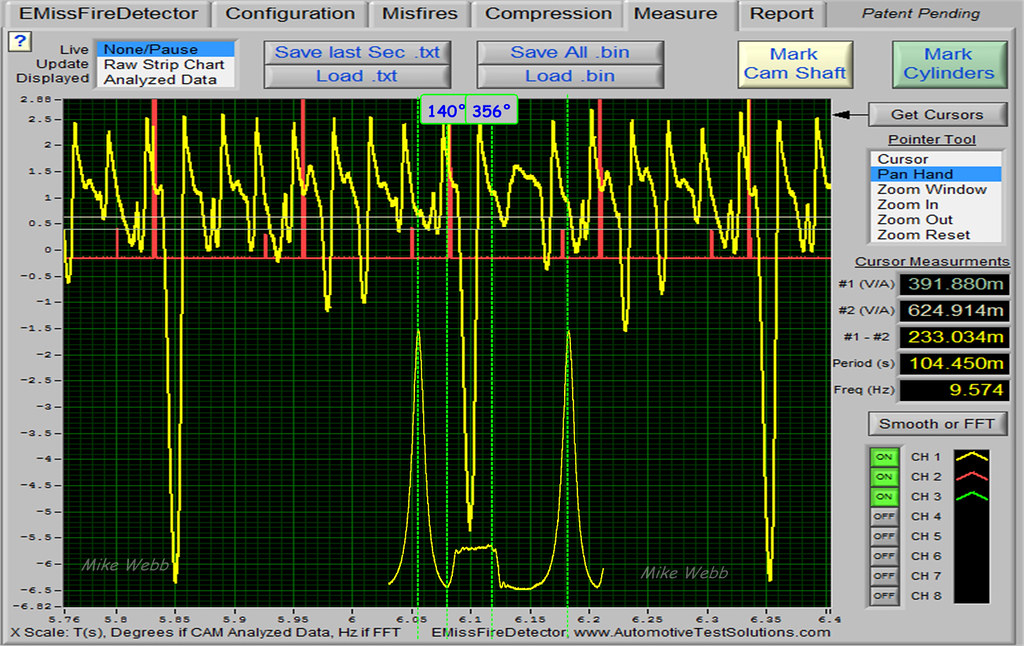

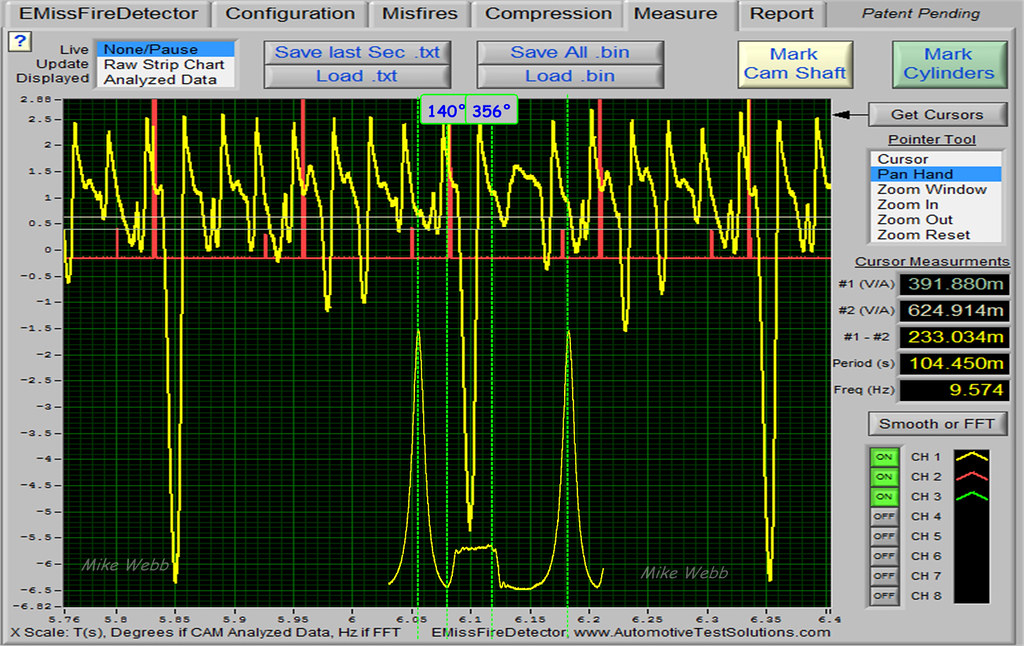

the upper yellow trace is exhaust pressure pulses

you can see a regular dip down , a vacuum pulse , and i have overlayed a running compression waveform (720 degrees) below in yellow also with Exhaust valve open EVO time marked by the green cursors.

sync to the pink / red trace .

the software normally picks this out for the user , i just made this screen cap so people can see what the software uses to arrive at the misfiring cylinder

Both programs Emisfire and AMD work very well

Last edited by mwebb; 08-01-2010 at 12:39 AM..

Reason: i am from ny- the image was missing ?

|

|

|

|

|

The Following User Says Thank You to mwebb For This Useful Post:

|

|

Today Today

|

|

|

|

Other popular topics in this forum...

Other popular topics in this forum...

|

|

|

|

06-17-2010, 12:32 PM

06-17-2010, 12:32 PM

|

#12 (permalink)

|

|

Administrator

Join Date: Dec 2007

Location: Germantown, WI

Posts: 11,203

Thanks: 2,501

Thanked 2,589 Times in 1,555 Posts

|

I was thinking this over this morning and I'm really thinking its the O2 sensor. The code doesn't pop up for ~20 seconds after the car has been running. Thats just about as much time as you need for it to go into closed loop mode.

I had planned on changing it out last night but had problems getting the old sensor out.

|

|

|

|

06-17-2010, 10:59 PM

06-17-2010, 10:59 PM

|

#13 (permalink)

|

|

Master EcoModder

Join Date: Jul 2009

Location: New York

Posts: 513

Thanks: 2

Thanked 101 Times in 74 Posts

|

bad guess - TEST, DO NOT GUESS

Quote:

Originally Posted by Daox

I was thinking this over this morning and I'm really thinking its the O2 sensor. The code doesn't pop up for ~20 seconds after the car has been running. Thats just about as much time as you need for it to go into closed loop mode.

I had planned on changing it out last night but had problems getting the old sensor out.

|

probably not -

if the 02 sensor was that bad - it would code the system

you do not have a code for the 02 sensor ....

and fuel trims would be out to lunch.

ie; sum of LTFT and STFT would be greater than +/- 25% from zero trim adjustment

test , do not guess .

it is always cheaper and better er

i recommend that you ;

DO NOT add a new problem by installing a FRED's 02 sensor

Frakin - Ridiculous - Engineering - Design .... FRED's

OEM only

a scan tool with GM Enhanced Data will have Mode 6 testing results

for the 02 sensor (s) , those test results will condemn or exonerate the 02 sensor as the culprit .

the system may give the rear 02 sensor some trim authority , an exhaust leak near the rear 02 sensor can skew fuel trim values ,

do you have an exhaust leak near the rear 02 sensor ?

would NOT cause p0300 though .... |

|

|

|

06-18-2010, 07:36 AM

06-18-2010, 07:36 AM

|

#14 (permalink)

|

|

Administrator

Join Date: Dec 2007

Location: Germantown, WI

Posts: 11,203

Thanks: 2,501

Thanked 2,589 Times in 1,555 Posts

|

Well, this guess was free. I had the O2 sensor from the other engine to swap in. But, it turns out you're right and it wasn't the O2 sensor. It stayed in closed loop while idling, but as soon as I put a significant load on it I got the blinking engine light again.

|

|

|

|

06-19-2010, 12:47 AM

06-19-2010, 12:47 AM

|

#15 (permalink)

|

|

Master EcoModder

Join Date: Jul 2009

Location: New York

Posts: 513

Thanks: 2

Thanked 101 Times in 74 Posts

|

Blinking CEL should set P030x where x is misfireing cylinder

the blinking CEL means

the ECM thinks you have a cat killing misfire , stop driving right now .

so

there should be a P030X DTC where X is the number of the misfiring cylinder .

try to get your car to someone with

a scan tool with

GM Enhanced software ,

i believe the scan tool you are using is not up to the challenge.

the other (unlikely) possibility may be

CKP CMP alignment or more likely in compatibility because the replacement engine has a different crankshaft or camshaft wheel / teeth set than the original engine .

IF hot intake vacuum is 20 to 21" then there is no Cam Crank misalignment error , what is your intake vacuum ?

|

|

|

|

07-12-2010, 11:38 AM

07-12-2010, 11:38 AM

|

#16 (permalink)

|

|

Administrator

Join Date: Dec 2007

Location: Germantown, WI

Posts: 11,203

Thanks: 2,501

Thanked 2,589 Times in 1,555 Posts

|

I tried the swapping in the 05 crankshaft position sensor over the weekend. It didn't help. I also removed the intake manifold and installed the 05 manifold in its place. That didn't help either.

I'm going to try swapping a few more parts before I bring it in somewhere. I'm thinking I'll try the EGR valve next. There isn't too much more I can replace though which really makes me wonder whats going on.

|

|

|

|

07-12-2010, 09:48 PM

07-12-2010, 09:48 PM

|

#17 (permalink)

|

|

Master EcoModder

Join Date: Jul 2009

Location: New York

Posts: 513

Thanks: 2

Thanked 101 Times in 74 Posts

|

basic s

test, do not guess

i was swagging that if there is a problem with CKP CMP sync , it might be caused by a difference in the pickup wheel / reluctor for the CKP or CMP sensor

not the sensor itself.

and

you have not yet measured intake vacuum

which is critical

you seem like a fairly wise individual ...

stop doing this all willy nilly , you need to start at the beginning and finish at the end -

the beginning is to confirm all the mechanical parts of the engine are in good shape

starting with intake vacuum measurement .

which should be about 20" at hot idle with ZERO flutter in the gauge .

what is your s ?

|

|

|

|

07-12-2010, 10:15 PM

07-12-2010, 10:15 PM

|

#18 (permalink)

|

|

Administrator

Join Date: Dec 2007

Location: Germantown, WI

Posts: 11,203

Thanks: 2,501

Thanked 2,589 Times in 1,555 Posts

|

19" pretty steady. There was a tiny bit of flutter, went between 19" - 19.25".

|

|

|

|

07-12-2010, 10:41 PM

07-12-2010, 10:41 PM

|

#19 (permalink)

|

|

Master EcoModder

Join Date: Jul 2009

Location: New York

Posts: 513

Thanks: 2

Thanked 101 Times in 74 Posts

|

next

Quote:

Originally Posted by Daox

19" pretty steady. There was a tiny bit of flutter, went between 19" - 19.25".

|

a wee bit on the low side

but good enough to confirm that the CAM and Crankshaft are in proper alignment and

.25" of flutter is a show stopper

is that with the engine at hot idle ? if yes , you have a leaking engine valve OR

the PURGE valve is operating while you are taking the measurement

so

put your finger on the PURGE valve , if it is ticking in time with the flutter

ok , disconnect it (the Purge Valve electrical connector only ) and repeat to see if the flutter is gone , if not

you will need to do a LEAK DOWN TEST on each cylinder in turn

a COMPRESSION test might not find this

================================

and

if possible , it would help if you could provide Long term fuel Trim at hot idle and hot 3k rpm , the generic tool like a scangauge2 can do this

|

|

|

|

07-13-2010, 07:19 AM

07-13-2010, 07:19 AM

|

#20 (permalink)

|

|

Administrator

Join Date: Dec 2007

Location: Germantown, WI

Posts: 11,203

Thanks: 2,501

Thanked 2,589 Times in 1,555 Posts

|

It wasn't completely warmed up, but the gauge was 1/4" of the way up. I'll check out the purge valve tonight and get back to you.

I'm not sure how you check fuel trims with the scangauge though?

|

|

|

|

|