Here is a little howto on how I apply composite as a wet layup over foam. The first thing that I would do is to make sure that you have the shape that you want. before you commit to using composite reinforcement.

I took the advice from euromodder and tapered the rear of the uprights in about half an inch over the length of 6-8"

I then started in with duct tape to finish putting radii on the areas where the shape didn't come out as well as I liked.

Got out the roll of cloth and made some adjustments and cut it off. I save the bits that are bigger than 6x6" as they can be used somewhere.

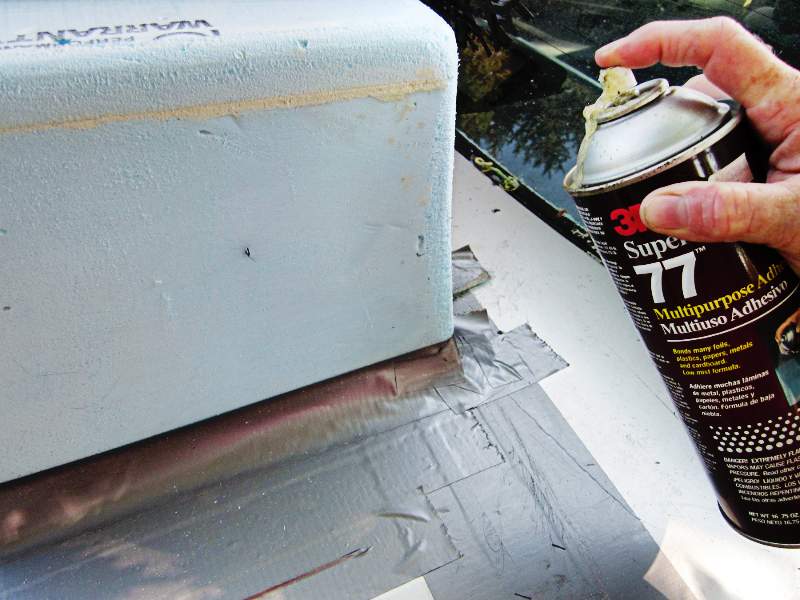

I use Super 77 spray to stick the composite onto the foam.

When it looks right I mix up a batch of epoxy and get my wife to paint it on.

We then cover the wet epoxy surface with polyester or nylon cloth. This ensures the edges are smooth.

The edges that don't want to lay down or are upside down we cover with duct tape.

Before it hardens completely (it is still green) is a good time to trim up any areas that might need it. I also peel off the cloth before it cures fully. Let it cure, then work on the surface with flox. Once the surface is to your liking take the parts off dissolve out the foam do a final trim and put them back on the car with shoe goo and rivets if you need them.

The cloth that I am using is 25 oz triaxial weave carbon fiber. It is really thicker than I would like but it makes a very hard part with a single layer. Fiber glass would work if you were to commit to 3-5 layers. I have the heavy carbon in my shop so that is what I used.