03-11-2010, 10:06 PM

03-11-2010, 10:06 PM

|

#261 (permalink)

|

|

EcoModding Lurker

Join Date: Mar 2010

Location: Alberta, Canada

Posts: 5

Thanks: 0

Thanked 2 Times in 1 Post

|

Very cool project

Very cool project

Wow, just read your whole thread here about your project.

You have outstanding fabrication skillz! my hat goes off to you.

I am just starting a conversion very similar in scope: dirt bike conversion (just picked up a 2004 Honda CRF230F with blown engine), using a higher voltage treadmill motor.

I have this spare treadmill motor that i have wanted to do this kind of thing with for a very long time.

I am concerned though about your motor choices & expectations...

I am a treadmill service tech by day - i have been working on treadmills for well over 10 years. Looking at that motor you bought, i can't help but wonder if you are going to be under-powered yet again..

I like the idea of using a treadmill motor along with a 96 volt pack - the lower amperage and higher voltage mean a more low cost controller could be used - but trying to find a charger for a 96 volt battery pack is proving difficult!

The motor I have and plan to use is rated 2.4 hp, 4000 rpm at 90 volts, 19 amps. Realistically about 1700 watts max. This motor is about 4.5" dia and 9" long - bigger than your latest choice i think. I am concerned this is not powerful enough still!

I have another motor that is 3.5 hp but at a very high 130 volts....

The motor you have chosen is one that i see in a lot of very entry level (cheap) treadmills, and often find blown/burnt controllers and motors in these treadmills - their ratings are usually exaggerated.

I don't want to bring you down, but just point out that you might need a bigger motor - the small ones might achieve the speed and torque you want for a little while, but may end up running too hot to have any durability.

My thinking is it's better to get a bit more motor than you really need, a controller that won't be maxing out, and things should stay nice and cool that way...

one more question; most of the motorcycle conversions I've seen are direct drive with one chain or belt and a bigger rear sprocket/pulley - are you not able to do this on your project? I would think it would result in less/load on the motor. I'm also a big fan of keeping things as simple as possible...

Please let me know your thoughts on motor power and single chain/large sprocket....

Edit: looking again at your motor pic - it says 2.65 hp right? These treadmill manufacturers really piss me off, it just isn't right what they do...

that 2.65 hp rating is "peak duty" not continuous duty. Peak duty is a number the marketing department pulls out of their a$$!.

My fingers are crossed for you, but be prepared to upgrade your motor...

If you wish, i could quote you a wholesale price on a bigger treadmill motor....

Last edited by rickc; 03-11-2010 at 10:30 PM..

|

|

|

|

Today Today

|

|

|

|

Other popular topics in this forum...

Other popular topics in this forum...

|

|

|

|

03-11-2010, 10:28 PM

03-11-2010, 10:28 PM

|

#262 (permalink)

|

|

Misanthropologist

Join Date: Sep 2008

Location: Sterling, VA

Posts: 383

BORK! - '89 Volvo 240 DL Wagon 90 day: 21.27 mpg (US)

Thanks: 2

Thanked 24 Times in 13 Posts

|

Quote:

Originally Posted by rickc

I am a treadmill service tech by day - i have been working on treadmills for well over 10 years. Looking at that motor you bought, i can't help but wonder if you are going to be under-powered yet again..

Please let me know your thoughts on motor power and single chain/large sprocket....

|

The constant rating for this motor is double that of the motors I had been using previously. For the most part I achieved the performance I wanted with the previous motors, but their armatures couldn't handle the higher RPMs they were experiencing at higher voltages. So it wasn't an issue of the wattage rating of the motor, but the voltage and speed at which it was intended to be run at.

My performance goals are rather low. I simply want to be able to reach a maximum speed between 38mph and 42mph. Acceleration being comparable to that of a 50cc bike.

I don't really have the need or budget for anything more powerful. If your goals are much higher than mine, then obviously you'll want a more substantial battery pack, controller, and motor.

And the choice of using a two-stage reduction was due to the need to have flexibility in ratios, not being able to mount the motor that low, and not wanting to have a huge final sprocket (which would both weigh a good deal, and look ugly). |

|

|

|

03-12-2010, 02:39 AM

03-12-2010, 02:39 AM

|

#263 (permalink)

|

|

EcoModding Lurker

Join Date: Mar 2010

Location: Alberta, Canada

Posts: 5

Thanks: 0

Thanked 2 Times in 1 Post

|

Ahh, i should have known. You have more of an eye for detail and esthetics than myself...

Let us know how that motor works out then.

|

|

|

|

03-12-2010, 10:32 AM

03-12-2010, 10:32 AM

|

#264 (permalink)

|

|

EcoModding Lurker

Join Date: Mar 2010

Location: Leicester UK

Posts: 16

Thanks: 0

Thanked 2 Times in 1 Post

|

Fabulous thread, thanks for sharing

Very near my ideal for a first EMC, but UK regs are/will be totally different so I will have to take these on board before committing Amps.

Having a quirky mind I considered leaving the ice engine, but replacing it with say an a Cox .049 which is electrically started using , say , a 5000W electric starter. So no official change of power/use but altogether quieter

No? Well it was only an idea

andrew |

|

|

|

03-12-2010, 03:15 PM

03-12-2010, 03:15 PM

|

#265 (permalink)

|

|

Misanthropologist

Join Date: Sep 2008

Location: Sterling, VA

Posts: 383

BORK! - '89 Volvo 240 DL Wagon 90 day: 21.27 mpg (US)

Thanks: 2

Thanked 24 Times in 13 Posts

|

Here's the cleaned and painted battery rack I finished working on yesterday.

Reinstalled the electrical system, gauge console, front fender, and controls.

Vinyl dyed the fake exhaust hose black, and lengthened the wires for the turn signals so I could route them through it.

Seen inbetween the bushings is a set-screw collar I made which is flanked by thrust bearings. It makes sure that the axle doesn't slide in either direction.

I also installed the newer and stronger 22T freewheel on the adapter I freed from a previously destroyed freewheel.

I'm now simply waiting on parts to install the belt reduction.

|

|

|

|

03-18-2010, 08:03 PM

03-18-2010, 08:03 PM

|

#266 (permalink)

|

|

Master EcoModder

Join Date: Feb 2010

Location: Wisconsin, United States

Posts: 479

Thanks: 6

Thanked 20 Times in 20 Posts

|

This is an awesome project. Perhaps you could increase the speed and range by making the bike more aerodynamic.

|

|

|

|

03-30-2010, 04:53 PM

03-30-2010, 04:53 PM

|

#267 (permalink)

|

|

Misanthropologist

Join Date: Sep 2008

Location: Sterling, VA

Posts: 383

BORK! - '89 Volvo 240 DL Wagon 90 day: 21.27 mpg (US)

Thanks: 2

Thanked 24 Times in 13 Posts

|

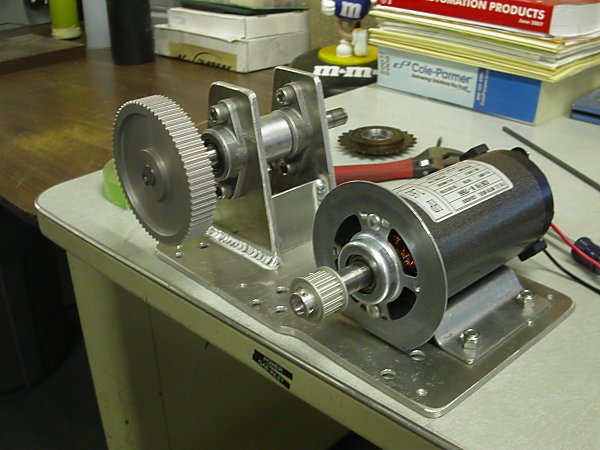

Bored out both pulleys, tapped one and on the other used a scroll saw to slowly cut a keyway into it.

I've ordered a belt, and parts to make a tensioner for the belt. |

|

|

|

04-05-2010, 10:32 AM

04-05-2010, 10:32 AM

|

#268 (permalink)

|

|

In God we trust!

Join Date: Mar 2009

Location: Gaiesville Georgia

Posts: 74

Thanks: 18

Thanked 4 Times in 4 Posts

|

Capt,

This is such a SWEET project! You've got mad-skilz in fabrication!! I am humbled and inspired! BEST of luck with this project! Don't EVER give up!!!

Anything I can do for you here in Central Florida(research/legwork) let me know!

Hip001

|

|

|

|

04-06-2010, 08:31 AM

04-06-2010, 08:31 AM

|

#269 (permalink)

|

|

Target 70mpg (UK) (58 US)

Join Date: Mar 2010

Location: Bucks, UK

Posts: 33

Clara - '94 Vauxhall Cavalier LS Last 3: 51.88 mpg (US)

Thanks: 0

Thanked 3 Times in 2 Posts

|

I love this project. Bike looks sick.

Hope you get the performance you want from it with the new motor

__________________

|

|

|

|

04-06-2010, 09:01 AM

04-06-2010, 09:01 AM

|

#270 (permalink)

|

|

Misanthropologist

Join Date: Sep 2008

Location: Sterling, VA

Posts: 383

BORK! - '89 Volvo 240 DL Wagon 90 day: 21.27 mpg (US)

Thanks: 2

Thanked 24 Times in 13 Posts

|

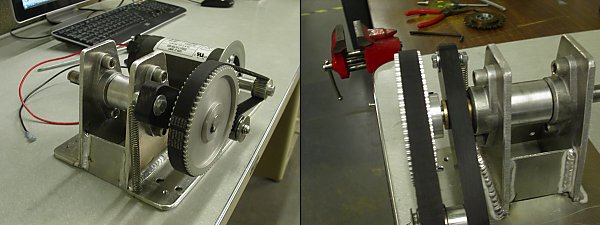

First stage reduction is complete. The belt tensioner has a flanged sleeve bearing and pivots on the reduction axle.

|

|

|

|

|