06-06-2015, 11:57 PM

06-06-2015, 11:57 PM

|

#11 (permalink)

|

|

EcoModding Apprentice

Join Date: Nov 2009

Location: Austin tx

Posts: 115

Thanks: 1

Thanked 22 Times in 14 Posts

|

Quote:

Originally Posted by slowmover

I think you've already made your goal. The age of the vehicle calls for new wiring, rubber replacement (from windows to suspension to body bushings), brake lines, etc. The reliability of the van is more to the point. I've owned plenty of old cars and FE is not the primary ownership cost. Especially at that purchase price.

Careful tire choice, axle and wheel bearings plus brake performance and replacing worn out steering would be highest on my list. Vans tend to be run hard and not cared for. "Economy" for most Americans is in doing no maintenance at all.

Can't wait to hear what shape the fuel tank is in (said with the patience of been there and done that). Your other posts indicate familiarity with mech issues, so I'd be more concerned over defining how this van is supposed to pay its way. An impulse buy, or filling a genuine need?

|

I was recently had to close the doors of my business doing custom diesel conversions on classic cars, due to my multiple sclerosis symptoms worsening. I never would have made it through the last couple builds without my apprentice there to catch me on some of the easy mistakes I was making.

This build is towards making a vehicle that could have a wheel chair lift if I loose my mobility, while still getting excellent fuel milage. The time to build it will be before that happens. It is used to haul materials for building the tiny house my wife and I will be living in, a lot of which is dumpstered. The fuel tank is great, will be adding a second like I said instead of a lowering kit and to help store my free wvo.

__________________

2007 Silverado 3500 classic duramax diesel, Allison 6 speed auto, extracab long bed. Doing head gaskets, will probably do econo tune and aero mods next.

Mad max would have driven a metro

|

|

|

|

|

The Following User Says Thank You to bondvagabond For This Useful Post:

|

|

Today Today

|

|

|

|

Other popular topics in this forum...

Other popular topics in this forum...

|

|

|

|

06-09-2015, 03:04 PM

06-09-2015, 03:04 PM

|

#12 (permalink)

|

|

EcoModding Apprentice

Join Date: Nov 2009

Location: Austin tx

Posts: 115

Thanks: 1

Thanked 22 Times in 14 Posts

|

Got the tail shaft from an e40d automatic ( the original transmission) cut it to length, then will weld it to a piece of 1/2" plate, that will bolt to the 6 speed output flange. This will mate to the original driveshaft. Drive shaft was mate out of some seriously hard stuff.

__________________

2007 Silverado 3500 classic duramax diesel, Allison 6 speed auto, extracab long bed. Doing head gaskets, will probably do econo tune and aero mods next.

Mad max would have driven a metro

|

|

|

|

06-09-2015, 04:08 PM

06-09-2015, 04:08 PM

|

#13 (permalink)

|

|

Master EcoModder

Join Date: Jan 2008

Location: Sanger,Texas,U.S.A.

Posts: 16,447

Thanks: 24,487

Thanked 7,417 Times in 4,805 Posts

|

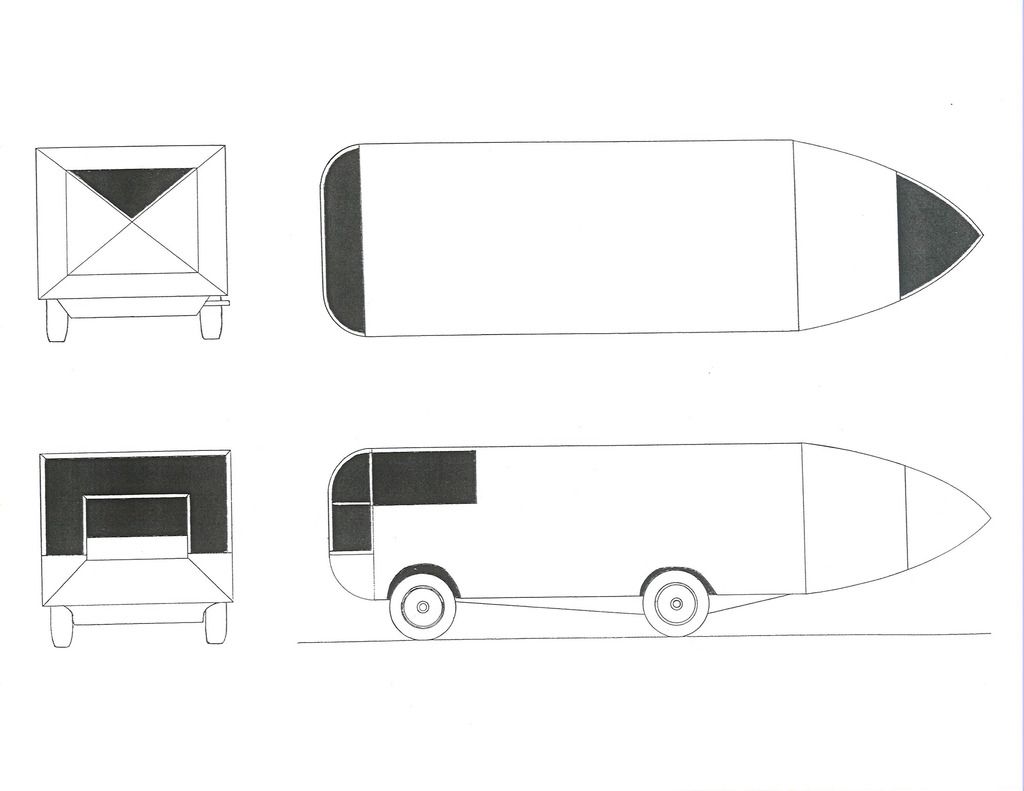

E350 image?

__________________

Photobucket album: http://s1271.photobucket.com/albums/jj622/aerohead2/

|

|

|

|

06-09-2015, 04:57 PM

06-09-2015, 04:57 PM

|

#14 (permalink)

|

|

Master EcoModder

Join Date: Jan 2008

Location: Sanger,Texas,U.S.A.

Posts: 16,447

Thanks: 24,487

Thanked 7,417 Times in 4,805 Posts

|

49-mpg

*you need to choose a target velocity and design for that road speed.It's the only speed at which you'll get 49-mpg under 'normal' circumstances.And it establishes the ROAD LOAD HORSEPOWER which aerodynamics and rolling resistance will factor into.

*We need a total weight to think about.(rolling resistance)

*We need a frontal area to play with.

*The drag coefficient is negotiable.

*A manual O.D. transmission is no better than an automatic O.D. transmission as far as mechanical efficiency.They're about 92%.

*Racing transmissions do all the under unity work within the transmission,leaving top gear as a 1:1 output,for 94% efficiency.

*Final gearing would be established at the differential.(98% efficiency)

*Drive shaft (98%).

*You're going after engine accessories so we can noodle those numbers accordingly (typically,engine-driven accessories absorb 2.2% of brake horespower)

*Then it comes down to the BSFC of the engine itself.

--------------------------------------------------------------------------

NASA got their Econoline down to Cd 0.238 without mirrors,but the cooling system was also closed off,so this adds some challenge.

*your wheel covers will help.

*Wheel skirts would help.

*Wheel fairings would help.

*Full belly pan is essential.

*The nose/air dam could still use some help.

*The exposed hinges need to faired.

*I'm unsure about whether a 'Trailer Tail' -type boat tail will do what you need.

__________________

Photobucket album: http://s1271.photobucket.com/albums/jj622/aerohead2/

|

|

|

|

|

The Following User Says Thank You to aerohead For This Useful Post:

|

|

06-11-2015, 12:07 PM

06-11-2015, 12:07 PM

|

#15 (permalink)

|

|

EcoModding Apprentice

Join Date: Nov 2009

Location: Austin tx

Posts: 115

Thanks: 1

Thanked 22 Times in 14 Posts

|

Thank you aero head for all the great input. My e-350 is actually a 1993, I think the one in your link is a 2012. Ford did a body change in 92 or 93 and redesigned for less drag. Supposedly my factory c of d is 0.37 not great but better than some of the stuff coming out today.

My van is also the factory long version, 20" longer behind rear wheels. I know from my time as a boat builder that the same design stretched was always more efficient for displacement hulls anyway, that do not plane.

I've been agonizing over doing a turbo or a tuned exhaust designed to be most efficient at intended rpm zone of 1400-1600rpms.

The only data I could find on that was for the 1.6 vw diesel. Both the na and turbo use the same compression ratio 23:1 and using the EPA specs the na diesel is 9% greater efficiency. All the other diesels I have found the factory drops the compression ratio for the turbo motors. This comparison is more like what I was contemplating of adding a turbo to the already higher 21.5:1 compression ratio of my na motor.

Both my 7.3 and the vw 1.6's are all mechanical idi's so without being an engineer I think This data dictates that I stay na and build a custom tuned set of headers and exhaust

__________________

2007 Silverado 3500 classic duramax diesel, Allison 6 speed auto, extracab long bed. Doing head gaskets, will probably do econo tune and aero mods next.

Mad max would have driven a metro

|

|

|

|

|

The Following 2 Users Say Thank You to bondvagabond For This Useful Post:

|

|

06-11-2015, 12:31 PM

06-11-2015, 12:31 PM

|

#16 (permalink)

|

|

EcoModding Apprentice

Join Date: Nov 2009

Location: Austin tx

Posts: 115

Thanks: 1

Thanked 22 Times in 14 Posts

|

While I agree on the highway mpg similarity between auto trans with lock up torque converter and manual trans with same overdrive ratio, my torque converter was slipping and it was actually cheaper to do this swap than repair the auto trans because of my scrounging/fabricating.

The 20.4 mpg 300+ mile baseline trip at 70mph was with a slipping torque converter.

Also the manual trans gives me the option of going slower in direct drive for an efficiency bump, and at city speeds the 6 speed manual should win.

Any input on order of operations for my proposed mods, after finishing trans swap? The goal being to go from greatest %mpg increase/$ to least of course.

__________________

2007 Silverado 3500 classic duramax diesel, Allison 6 speed auto, extracab long bed. Doing head gaskets, will probably do econo tune and aero mods next.

Mad max would have driven a metro

|

|

|

|

|

The Following User Says Thank You to bondvagabond For This Useful Post:

|

|

06-11-2015, 05:19 PM

06-11-2015, 05:19 PM

|

#17 (permalink)

|

|

Master EcoModder

Join Date: Jan 2008

Location: Sanger,Texas,U.S.A.

Posts: 16,447

Thanks: 24,487

Thanked 7,417 Times in 4,805 Posts

|

turbo

Quote:

Originally Posted by bondvagabond

Thank you aero head for all the great input. My e-350 is actually a 1993, I think the one in your link is a 2012. Ford did a body change in 92 or 93 and redesigned for less drag. Supposedly my factory c of d is 0.37 not great but better than some of the stuff coming out today.

My van is also the factory long version, 20" longer behind rear wheels. I know from my time as a boat builder that the same design stretched was always more efficient for displacement hulls anyway, that do not plane.

I've been agonizing over doing a turbo or a tuned exhaust designed to be most efficient at intended rpm zone of 1400-1600rpms.

The only data I could find on that was for the 1.6 vw diesel. Both the na and turbo use the same compression ratio 23:1 and using the EPA specs the na diesel is 9% greater efficiency. All the other diesels I have found the factory drops the compression ratio for the turbo motors. This comparison is more like what I was contemplating of adding a turbo to the already higher 21.5:1 compression ratio of my na motor.

Both my 7.3 and the vw 1.6's are all mechanical idi's so without being an engineer I think This data dictates that I stay na and build a custom tuned set of headers and exhaust

|

Has Gale Banks offered a turbo package for your powerplant? They include tuned exhaust with their kits.It's all dyno-tested.

__________________

Photobucket album: http://s1271.photobucket.com/albums/jj622/aerohead2/

|

|

|

|

06-11-2015, 05:32 PM

06-11-2015, 05:32 PM

|

#18 (permalink)

|

|

Master EcoModder

Join Date: Jan 2008

Location: Sanger,Texas,U.S.A.

Posts: 16,447

Thanks: 24,487

Thanked 7,417 Times in 4,805 Posts

|

order

Quote:

Originally Posted by bondvagabond

While I agree on the highway mpg similarity between auto trans with lock up torque converter and manual trans with same overdrive ratio, my torque converter was slipping and it was actually cheaper to do this swap than repair the auto trans because of my scrounging/fabricating.

The 20.4 mpg 300+ mile baseline trip at 70mph was with a slipping torque converter.

Also the manual trans gives me the option of going slower in direct drive for an efficiency bump, and at city speeds the 6 speed manual should win.

Any input on order of operations for my proposed mods, after finishing trans swap? The goal being to go from greatest %mpg increase/$ to least of course.

|

*The corporate guys do the load reduction first,with say,all synthetics,LRR tires,and aero,then try and match the gearing to get the engine to it's sweet-spot as far as BSFC goes.

-------------------------------------------------------------------------

*For all tires sold in the state of California,the law requires that coefficients of rolling force be provided to the consumer.If when you shop for replacement rubber,you should be able to get this info.

*You may already have all-synthetic lubes in the van.

*Aero drag reduction would provide the greatest savings on the HWY.Around town it wouldn't mean diddly-squat.You'll have to consider your needs 'n see what might fit in.NASA got to Cd 0.238 and had still left some fruit on the tree.

*Weight reduction is kinda meaningless in all-highway operation.Adding a half-ton to my CRX only cost me 2 mpg.Around town,weight savings WOULD mean $ savings.

__________________

Photobucket album: http://s1271.photobucket.com/albums/jj622/aerohead2/

|

|

|

|

|

The Following 2 Users Say Thank You to aerohead For This Useful Post:

|

|

06-12-2015, 03:23 PM

06-12-2015, 03:23 PM

|

#19 (permalink)

|

|

EcoModding Apprentice

Join Date: Nov 2009

Location: Austin tx

Posts: 115

Thanks: 1

Thanked 22 Times in 14 Posts

|

I made some good progress yesterday. Got the transmission crossmember from the auto trans altered so it would fit the 6 speed.

I bolted up the drive shaft adapter which is a length of auto trans output shaft welded to a flange that bolts to new trans output flange. This slips into the internally splined end of the stock driveshaft to give me the "slip yolk" effect needed when the suspension geometry changes the length of the drive shaft. I had read that max allowable runout on a driveshaft was 0.003" and bothe the slip yolk connection and the trans output flange have about 0.030" of play. Will retorque output flange bolt and grease slip yolk to see if that helps. The splines are all nice and square no sharpening indicating wear.

@aerohead: Banks and ATS and someone else all make turbo setups for my engine, but I believe them to be optimized for maximum reliable power rather than maximum reliable efficiency. That is why I was so excited to find that EPA vw data that seams to show that na is more efficient than turbo in same displacement, same compression ratio engine.

@aerohead: when you say the corporate guys do load reduction first then pick power sufficient to the task, are you meaning for engine design? Cause an engine swap is not in the cards right now. If you meant picking final drive ratio than that is a great point. If my motor's peak efficiency is fixed at peak torque it is 1400rpms. The overdrive in my trans is fixed at 0.72, or 1:1 in 5th for 2% efficiency bump. The variables than are tire size and rear end ratio. Thanks to aerohead I will put changing these after load reduction(although tire size/weight/rolling resistance is kind of both.) the tallest gears for my full floating dana 60 rear axle from the factory are 3.33:1 (easy to find used) and 3.23:1 (never Sean them new or used). With a little milling dana 61 gears can be used, giving you 3.08:1 and 2.73:1 if necessary. For those with the machining skills to try that at home just know the ring gear bolt holes are hardened crazy hard and use appropriate best practices.

Reducing drive belt loads is high on my list but I have a few differences from Jacob azizas project. I had a 1967 ford f350 with manual brakes that I used for hauling heavy loads and the lack of a brake booster never bothered me. It was drums all around so might be tough finding a master cyl for brakes that was sized for front discs and rear drums. Am I correct in assuming that the electric vacuum pumps draw no load as long as you are not braking? If that is so, then I guess there would be no benefit to going to manual brakes except maybe slight reliability increase.

The other variation is that I require A/C for medical reasons. Although a young fit 32 year old I was recently diagnosed with multiple sclerosis, which makes me very heat sensitive. I have the cooling vests and all that but here in texas when it's 100*f and 98% humidity I need the real deal. I've investigated using a prius electrical a/c compressor, they run off the hybrid pack so would require a heavy battery bank. Other ideas are an insulated partition between front seats and cargo area. Also cops use these hoses that clip on the a/c vent to direct cold air under their body armor, something like that might help, since the engineering problem is to cool me not the interior car air.

Another fun symptom of m.s. Is extreme fatigue. It is so bad that the social security department just renamed it as ms lassitude to signify that it is worse than extreme fatigue caused by many other illnesses. Part of my reason for getting a van was to have an area in the back I could sleep in so I was not shackled to my house for "nap time" allowing me to venture farther from home or stay out longer. In the summer this would dictate some sort of a/c that could cool me while I slept for up to 4 hours. If anyone has any brilliant ideas on how to pull off this space ship issue I'd love to hear it. My motor burns 0.25 u.s. Gallons of diesel and puts out about 50hp at idle so I could potentially run factory a/c, maybe hosed to inside an insulated "sleeping bag" with a thermostat pickup inside that would kill the a/c compressor clutch reducing engine load/fuel usage. One of my last jobs was as a long haul truck driver, and the semis all have diesel or battery powered climate control units that can be found used for about $1000. This would be an expensive option, and I believe the diesel ones burn similar g/hr as my engine at idle, plus another motor to maintain etc.

Anyway, sorry if that is over sharing, but it is pertinent to my quest for efficiency given my constraints. And if anyone has some good ideas on how to accomplish my efficiency goals it will be the helpfull people on this forum.

__________________

2007 Silverado 3500 classic duramax diesel, Allison 6 speed auto, extracab long bed. Doing head gaskets, will probably do econo tune and aero mods next.

Mad max would have driven a metro

Last edited by bondvagabond; 06-12-2015 at 03:33 PM..

|

|

|

|

|

The Following User Says Thank You to bondvagabond For This Useful Post:

|

|

06-12-2015, 04:37 PM

06-12-2015, 04:37 PM

|

#20 (permalink)

|

|

Master EcoModder

Join Date: Sep 2010

Location: Denver, CO

Posts: 1,300

Thanks: 315

Thanked 179 Times in 138 Posts

|

Some people I know with MS practice Tai Chi regularly and they say it greatly alleviates their symptoms. I've been doing it for 20 years and have never felt better, and I am 50 years old.

__________________

I'm not coasting, I'm shifting slowly.

|

|

|

|

|