06-21-2011, 12:59 PM

06-21-2011, 12:59 PM

|

#271 (permalink)

|

|

Master EcoModder

Join Date: May 2008

Location: Maynard, MA Eaarth

Posts: 7,908

Thanks: 3,475

Thanked 2,953 Times in 1,846 Posts

|

I have ordered the Phlatprinter 3! Now the waiting for UPS truck begins...

|

|

|

|

Today Today

|

|

|

|

Other popular topics in this forum...

Other popular topics in this forum...

|

|

|

|

06-22-2011, 09:53 PM

06-22-2011, 09:53 PM

|

#272 (permalink)

|

|

MPG Militia HMV-25E80+A

Join Date: Mar 2011

Location: Vermont, USA

Posts: 823

Thanks: 191

Thanked 144 Times in 98 Posts

|

Did it come yet  ?

To quote Inudo Montoya from "The Princess Bride"..."I hate waiting."

How much time is that puppy going to save you with your build(s)? |

|

|

|

06-23-2011, 12:56 PM

06-23-2011, 12:56 PM

|

#273 (permalink)

|

|

Master EcoModder

Join Date: May 2008

Location: Maynard, MA Eaarth

Posts: 7,908

Thanks: 3,475

Thanked 2,953 Times in 1,846 Posts

|

It will save many, many hours of work.  I would have to plot everything on paper, then cut it all out by hand with scissors, then spray mount it on the foam, then cut it out by hand either on a bandsaw or jigsaw or with a hacksaw blade. (And I have to then shape all the steps...)

With the Phlatprinter 3, I just "print" in from my computer to the foam, and it will also do about half of the 3D shaping. |

|

|

|

07-02-2011, 10:59 AM

07-02-2011, 10:59 AM

|

#274 (permalink)

|

|

CFECO

Join Date: May 2008

Location: Vail, AZ.

Posts: 552

Thanks: 174

Thanked 60 Times in 56 Posts

|

Neil,

Here are some photos of my X-Prize car beginnings. Have you tried to straighten out the leaf blower airflow using stacks of tubing, as Mythbusters did with the boxes of straws? The white rectangular tube in the photo is that "pultruded" fiberglass I had mentioned. I was thinking, to make fast body modifications without having to use fiberglass to smooth the foam, perhaps you could use shrink wrap, as long as it didn't melt your foam!

Chuck

|

|

|

|

|

The Following User Says Thank You to CFECO For This Useful Post:

|

|

07-02-2011, 11:01 AM

07-02-2011, 11:01 AM

|

#275 (permalink)

|

|

CFECO

Join Date: May 2008

Location: Vail, AZ.

Posts: 552

Thanks: 174

Thanked 60 Times in 56 Posts

|

The rest of the photos...

|

|

|

|

07-02-2011, 12:23 PM

07-02-2011, 12:23 PM

|

#276 (permalink)

|

|

Master EcoModder

Join Date: Jul 2011

Location: Ann Arbor, Michigan

Posts: 4,208

Thanks: 140

Thanked 2,824 Times in 1,981 Posts

|

A very cool project, keep going with it.

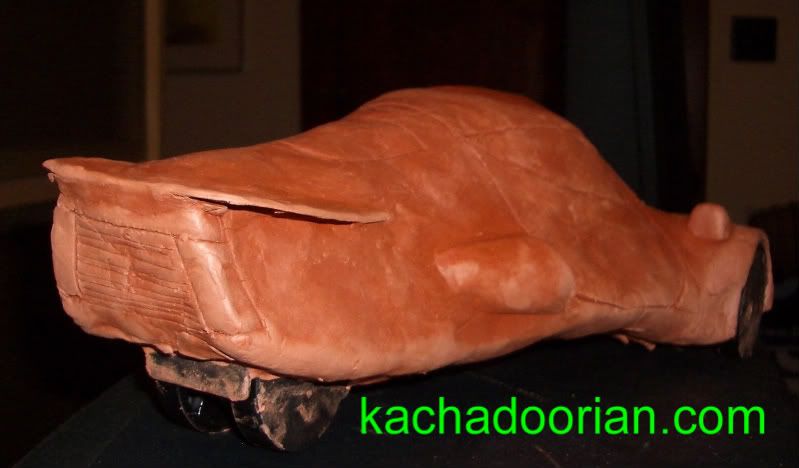

I might have you beat on the "Odd Scale" though. A clay study I did back in 2004 just for fun.

http://s184.photobucket.com/albums/x...rial%20Design/

It's almost eight feet wide, but the lower rolling resistance of three wheels might make up for that.

__________________

George

Architect, Artist and Designer of Objects

2012 Infiniti G37X Coupe

1977 Porsche 911s Targa

1998 Chevy S-10 Pick-Up truck

1989 Scat II HP Hovercraft

You cannot sell aerodynamics in a can............

Last edited by kach22i; 07-02-2011 at 12:45 PM..

|

|

|

|

07-02-2011, 12:41 PM

07-02-2011, 12:41 PM

|

#277 (permalink)

|

|

CFECO

Join Date: May 2008

Location: Vail, AZ.

Posts: 552

Thanks: 174

Thanked 60 Times in 56 Posts

|

Thanks! That was from several years ago, and I have lost the shop to work in, but I still have all the engine parts. I have joined a local electric car club that is very interesting. There are quit a few people converting cars over to electric drive here, that I had no idea about. Watching Neil's progress IS inspiring. As soon as I find a workspace I will continue, even if the X-Prize didn't happen. I think as soon as one car is on the road, the interest will be self generating.

Chuck

|

|

|

|

07-02-2011, 05:35 PM

07-02-2011, 05:35 PM

|

#278 (permalink)

|

|

Master EcoModder

Join Date: May 2008

Location: Maynard, MA Eaarth

Posts: 7,908

Thanks: 3,475

Thanked 2,953 Times in 1,846 Posts

|

Thanks guys -- my Phlatprinter 3 is #80, and it should be shipped in less than 30 days. They are a small company, and they often video the packing process for each unit they ship.

|

|

|

|

07-09-2011, 09:48 PM

07-09-2011, 09:48 PM

|

#279 (permalink)

|

|

Master EcoModder

Join Date: May 2008

Location: Maynard, MA Eaarth

Posts: 7,908

Thanks: 3,475

Thanked 2,953 Times in 1,846 Posts

|

|

|

|

|

08-12-2011, 10:22 AM

08-12-2011, 10:22 AM

|

#280 (permalink)

|

|

Master EcoModder

Join Date: May 2008

Location: Maynard, MA Eaarth

Posts: 7,908

Thanks: 3,475

Thanked 2,953 Times in 1,846 Posts

|

UPS delivered two good size boxes a few days ago (I was away for a week), and I will be assembling my Phlatboyz 3-axis CNC machine later today!

Then I will be learning the ins and outs of SketchUp and the slicing and g-code plugins -- and hopefully be able to start producing 2" thick sections of the full size foam core and be on my way to building a working prototype!

|

|

|

|

|