07-15-2010, 07:10 PM

07-15-2010, 07:10 PM

|

#81 (permalink)

|

|

Master EcoModder

Join Date: May 2008

Location: Maynard, MA Eaarth

Posts: 7,908

Thanks: 3,475

Thanked 2,953 Times in 1,846 Posts

|

If I did a donor chassis, I'd start with a front wheel drive hatchback, like my Scion xA or a Honda Fit. But, to get anywhere near the aero of this design, I'd have to pare it down a lot, like Dave Cloud's Dolphin.

I know it is a Large Amount of Work -- but I am led by the many X-Prize teams (especially Illuminati!) who built cars from scratch, or near scratch. Several of them built hybrids, to boot. I would seek a bunch of help, and probably would buy the drivetrain, at least.

|

|

|

|

Today Today

|

|

|

|

Other popular topics in this forum...

Other popular topics in this forum...

|

|

|

|

07-15-2010, 07:11 PM

07-15-2010, 07:11 PM

|

#82 (permalink)

|

|

Master EcoModder

Join Date: May 2008

Location: Maynard, MA Eaarth

Posts: 7,908

Thanks: 3,475

Thanked 2,953 Times in 1,846 Posts

|

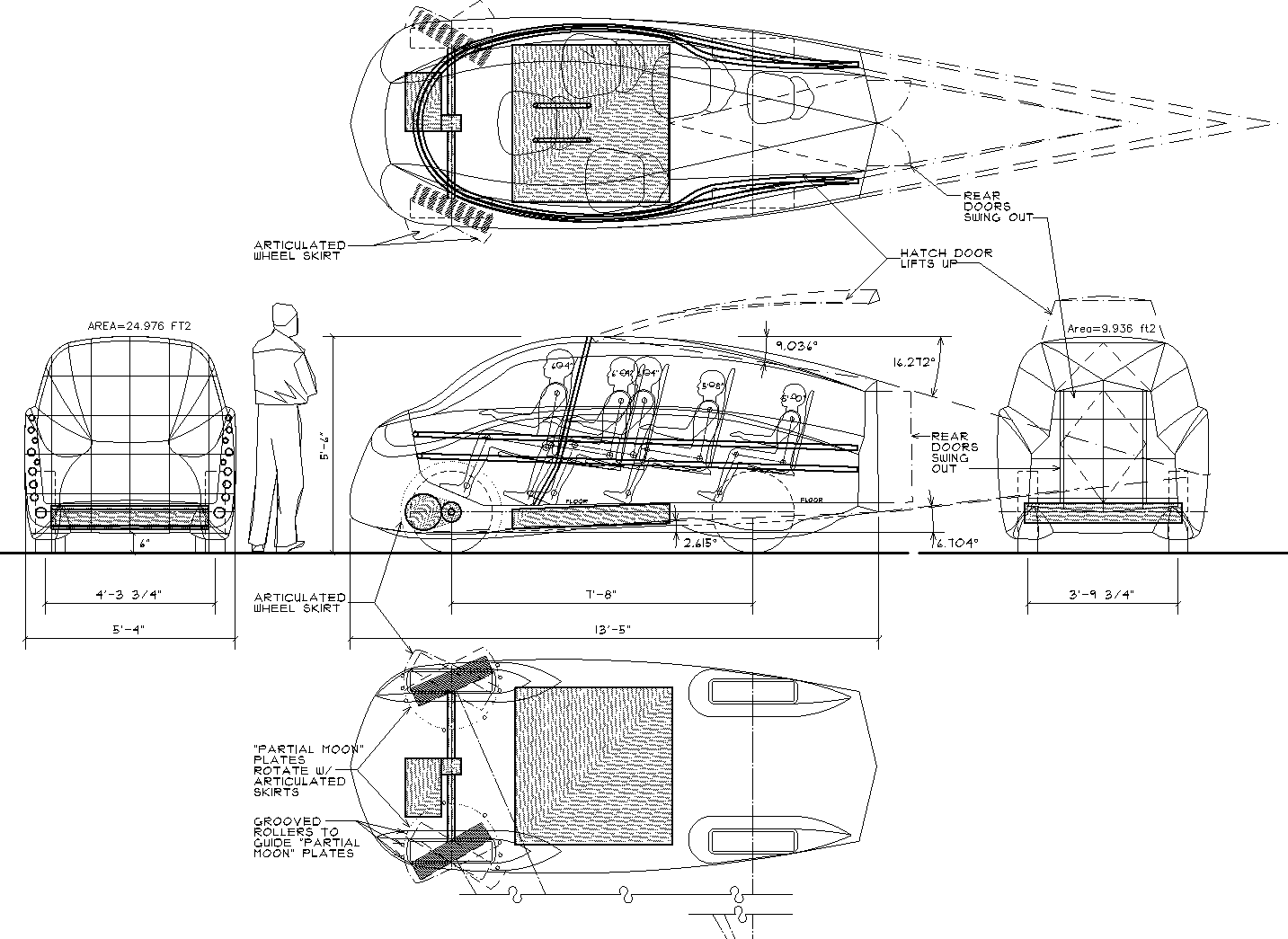

I do have two structural connections from the floor to the roof, right behind the driver's seat, as well. See the side view in this drawing:

With no side doors (ideally, if this entry scheme works), then the only structural "holes" in the front and sides of the car, are the windows. With conventional side doors, the openings are much taller, and the doors are essentially disconnected structurally; and they do not support the roof much. The windows pillars are spanning a much shorter distance, and so they do not have to be as thick as a "normal" car.

The top hatch door and the rear doors would have multiple latches to structurally join them to the rest of the car. So, I am aiming for a composite foam sandwich structure (to provide good strength, light weight, and thermal insulation), with continuous wraparound structural cage on the front and sides; room for 4-5 people (the front 3 figures are 6'-4" tall, and the next 2 are 5'-8 and 5'-0" respectively), enough room in the floor for a ~32-50kWh prismatic battery pack, hopefully weighing 1600-1800 pounds, and having a CdA >3.75 sq ft and maybe as low as 2.75.

The rear hatch would raised and the rear door(s) would swing open, and you then step up on the rear floor (about 14" up IIRC?), and after you move into the back, you turn around and close the rear door(s), and then walk down the "aisle" past the staggered offset seats, ducking a little more as you get closer to the driver's seat. You then sit down from the left side, sliding your butt into the seat (the space between the driver's seat and the one passenger's seat on the left side of the car is bigger than the right side). You then push a button/pull a lever to drop and close the rear hatch door; and it latches in at least 3 places. So, it is firmly "joined" to the sides and rear of the car by the latches, and to the top by the hinges. Please note, the hatch door provides some sheltering from precipitation, so the inside of the car is not directly getting rained/snowed/sleeted in...

Oh, if a second means of egress is required, I'd put a hatch door in the roof just above the driver. And if the rear hatch entry proves impractical, then I'd go with side doors that have multiple latches. This would add some weight, though; and I don't think it would be as strong, either.

The other purpose/result of the staggered/offset seats is the legroom is flexible, and people can stretch out to the side, to help avoid getting cramped or uncomfortable. Also, note these seats are curved mesh surfaces, stretched over frames; to provide comfortable ergonomic seating (the proper angles and shapes are key!), while taking up a minimum of space and good air circulation.

Something I have forgotten to mention before now is the frontal area is shaped somewhat close to square -- this encloses the most interior volume for a given frontal area, and that makes it easier/more practical to use. You can get upright seating (which I find very comfortable), and that in turn allows you to fit more "rows" of seats than you otherwise would. This car is less than 14' long, and just 5'-4" wide. Naturally, I'd use side video mirrors; or optical mirrors on the inside, to avoid the additional aero drag.

I do hope to build it, sooner rather than later; but if you want me to send you the SketchUp model and/or the CAD drawings, so you or someone you know wants to build it, then I'd be happy to send them to you. |

|

|

|

07-30-2010, 10:33 AM

07-30-2010, 10:33 AM

|

#83 (permalink)

|

|

Quest for a 400 mile tank

Join Date: Jul 2009

Location: West Michigan

Posts: 50

Thanks: 43

Thanked 15 Times in 10 Posts

|

|

|

|

|

07-30-2010, 03:40 PM

07-30-2010, 03:40 PM

|

#84 (permalink)

|

|

...beats walking...

Join Date: Jul 2009

Location: .

Posts: 6,190

Thanks: 179

Thanked 1,525 Times in 1,126 Posts

|

...cute looking little car...and the name JOULE is also appropriately cute.

|

|

|

|

07-31-2010, 01:38 AM

07-31-2010, 01:38 AM

|

#85 (permalink)

|

|

EcoModding Apprentice

Join Date: Jun 2010

Location: mass

Posts: 181

Thanks: 4

Thanked 9 Times in 8 Posts

|

This is quite the project!

My first thoughts on it (something in here might help you);

-The back end is still rather large (he he he), which is difficult to address with out major reworking, or extension. If you could bring the roof down a little more, it would help a lot. If the batteries/cap.'s were not adding to the floor you could nab an extra few inches. Also a everyone who is 6'4" is used to a reclined seat when not in a truck (I'm 6'3"). If you can squeeze it down a little, and then extend it in the back even just 6", maybe just like a cammback thing...

-Safety, I would be scared as hell to take that thing on 128! For areo you could go a lot shorter in the front, but it's unpleasant to use your legs as a crumple zone. I think for the safety of this car you should extend the front out dramatically, and or change the seating arrangements. Would a 4 seater not work for you?

Other thoughts in no particular order; do you need 2 wheels in the back? I like the hatch door thing. There are some things that are not easy to make yourself or even have custom made, one of those is a windshield. It may be best to find a good sized and shaped one to base the rest of the design off of. Have you toyed with different bat/cap placements?

|

|

|

|

08-04-2010, 07:00 PM

08-04-2010, 07:00 PM

|

#86 (permalink)

|

|

Master EcoModder

Join Date: May 2008

Location: Maynard, MA Eaarth

Posts: 7,908

Thanks: 3,475

Thanked 2,953 Times in 1,846 Posts

|

Okay, if you can clarify/correct me on the construction process, here's what I am thinking of doing:

Cut plywood former sections about every foot -- I can plot full size templates/patterns from DataCAD, and then use spray adhesive to stick 'em to the plywood. I will lay them out in DataCAD to try and fit as many as possible on each sheet. I'd like to be able to test the physical size and layout of the entry method and seat layout etc., before committing to build this car.

Now, I want to have a composite foam sandwich monocoque, both for strength and for thermal insulation, so do I need to form the inner walls on the inside of the formers first, and then do the outer surface, and then foam in between?

How do I best form the surface using the formers?

Do I need to use Styrofoam and carve it, or can I use wires and/or screening as a substrate for the composite?

It is okay to leave the plywood in place and have it as part of the structure, or is is better to pull it out and then rejoin the surfaces with spacers/foam?

Is fiberglass significantly less expensive than carbon fiber, and what are the advantages/issues with each?

I can cut the plywood so that the windows are slightly recessed, to form the lip/flange -- should the windows just be left open and trim the edges, or does it help to cover them over completely and then cut out the openings?

For the main hatch door, and the rear doors, should they be formed as part of the whole outer skin, and then cut out? Or, should the opening be left out of the main piece and then make the doors themselves separately?

I want to form a surrounding "beam" around the front and sides of the passenger compartment (which will double as the main air duct into the passenger compartment) -- I hope to have it flush on the inside, and let it into the formers. If the beam was metal, it could be hollow -- can it be made from composite and be hollow?

I'm trying to figure out how to best do the crumple zone in the front: a tubular subframe or a composite structure? Have you seen "crush cones" used between a structural bumper and the firewall/structural passenger cell?

How does the suspension get attached to the monocoque -- do reinforcing plates need to be embedded, or...?

I'm hoping to hear from FVT about the size of their battery pack, so I can try and lay out how it will fit inside the floor. I would ideally try and at least have the space for a really big battery pack (50-60kWh!!) so I can get 300-400 mile range. This would be incredible if it could be made to fit!

I would love to hear whatever your thoughts are! Thanks in advance.

Some more slightly revised images of the SketchUp model:

Link to my blog: http://neilblanchard.blogspot.com/20...e-project.html

Last edited by NeilBlanchard; 09-12-2010 at 03:36 PM..

|

|

|

|

08-05-2010, 12:29 AM

08-05-2010, 12:29 AM

|

#87 (permalink)

|

|

EcoModding Apprentice

Join Date: May 2008

Location: N. Saskatchewan, CA

Posts: 1,805

Thanks: 91

Thanked 460 Times in 328 Posts

|

Building Composite Monocoques

>Okay, if you can clarify/correct me on the construction process, here's what I am thinking of doing:

>Cut plywood former sections about every foot -- I can plot full size templates/patterns from DataCAD, and then use spray adhesive to stick 'em to the plywood. I will lay them out in DataCAD to try and fit as many as possible on each sheet. I'd like to be able to test the physical size and layout of the entry method and seat layout etc., before committing to build this car.

---You might want to do a mock-up that includes many structural details, for practise and clarity. Incorporating a mock-up into a finished vehicle would be wonderfully economic of material, but not likely to produce a good part. I saw a boat for sale once, priced about equal to the materials someone had used, but, sadly, they were now worth less than they had been.

Of homebuilt aircraft, 10% are finished by the 1st builder, 10% by the 2nd builder to take over, and 10% by the third. That's for a simple machine, built to plans, with a support community that often teams up.

In choosing a structural foam, you need to run a few numbers, and then, to make sure your foam matches them, you don't use foam-in-place, but buy sheets. Airex is wonderfully tough, with a bit of flex that makes it easy to work with, and several other types could conceivably be heat-formed to fit between plywood formers, but it is probably faster to just cut foam profiles, inside and out, and glue them into a stack that just needs to be sanded down to smooth to form the core of a sandwich. That way you could check the shape for cheap, with options to cut 'n' try. No plywood to complicate things.

For a shape like yours, sheets might also be laid as planks over temporary cardboard templates. The inside seams can be done with fiberglass tape, and the outside ones sanded to a round contour before 'glassing.

>Now, I want to have a composite foam sandwich monocoque, both for strength and for thermal insulation, so do I need to form the inner walls on the inside of the formers first, and then do the outer surface, and then foam in between?

>How do I best form the surface using the formers?

Do I need to use Styrofoam and carve it, or can I use wires and/or screening as a substrate for the composite?

It is okay to leave the plywood in place and have it as part of the structure, or is is better to pull it out and then rejoin the surfaces with spacers/foam?

Is fiberglass significantly less expensive than carbon fiber, and what are the advantages/issues with each?

---Fiberglass is what you learn on, because you can see through a well-made part. An experienced worker can get more strength from 'glass than an amateur can get with carbon. You can look up the current numbers on cost and strength, but what you are really buying is crash safety - toughness - and the aramids or Spectra are best for that. They are tricky to engineer because they are far stronger in tension than compression, and usually used with either glass or carbon compression faces, or a blend. The basic working structural loads can be taken by a sandwich so light you could easily kick through it.

You have to plan to never sand aramid to a smooth finish, and to minimize toxic carbon dust. Carbon is not particularly strong or tough but it is very stiff, and that can upset stress patterns in combinations. J.E. Gordon is a good author to convey a quick, painless grasp of the overall structural issues, and Andy Marshall, among others, has written on how to do things like seat-belt anchors, wheel mounts, and so on for homebuilt aircraft. The Gougeon Bros have some good how-to publications for glass 'n' goo with cellular hydrocarbon cores.

That door arrangement was tried on the (only) Mohs Ostentatienne Opera Sedan.

>I can cut the plywood so that the windows are slightly recessed, to form the lip/flange -- should the windows just be left open and trim the edges, or does it help to cover them over completely and then cut out the openings?

For the main hatch door, and the rear doors, should they be formed as part of the whole outer skin, and then cut out? Or, should the opening be left out of the main piece and then make the doors themselves separately?

---The more details you can carve into the foam or other molds, the less re-work there is to getting done. As these things go, carving up a sandwich part into panels is pretty decent, since they don't warp much without a frame. You can 'glass the cut edges, re-assemble with masking tape, and then stick on some weatherstripping, 'glass over that, and have a decent door jamb. Wax and filler give a hairline seam on the surface with little work. Leaving a little dip near the future edges to allow for that edge wrap is a big time-saver if you want strong, smooth, light parts.

>I want to form a surrounding "beam" around the front and sides of the passenger compartment (which will double as the main air duct into the passenger compartment) -- I hope to have it flush on the inside, and let it into the formers. If the beam was metal, it could be hollow -- can it be made from composite and be hollow?

---Sure. Sometimes we use a temporary foam part to form a tube. You can also get a tube by slitting a cardboard tube to let it bend, and 'glassing over that.

>I'm trying to figure out how to best do the crumple zone in the front: a tubular subframe or a composite structure? Have you seen "crush cones" used between a structural bumper and the firewall/structural passenger cell?

--- Foam makes very good crush zones. Cones are a lot of work - maybe good in production, but not really needed. You can cut foam blocks and add internal 'glass partitions as cones or whatever if you want. That's a good way to get bulkheads to help spread out point loads.

>How does the suspension get attached to the monocoque -- do reinforcing plates need to be embedded, or...?

---Ya gotta calculate the loads, and add layers and/or panels appropriately. Generally, it is handy to build up a strong point with multiple layers of tape, and fan them out to distribute the force to an appropriate perimeter. Sometimes, you need denser foam in some spots. Adding metal can be a lot of hassle to minimize stress concentrations, but sometimes there's no other way. Bolts can be run into cast resin threads in many situations. See "potting."

>I'm hoping to hear from FVT about the size of their battery pack, so I can try and lay out how it will fit inside the floor. I would ideally try and at least have the space for a really big battery pack (50-60kWh!!) so I can get 300-400 mile range. This would be incredible if it could be made to fit!

---Batteries are something that can be tucked away in several places, and sometimes left out for in-town use, if the balance is still OK. But you are more likely to want load levellers, or at least progressive springs. There's more than a bit of art to a good ride.

>I would love to hear whatever your thoughts are! Thanks in advance.

---Vinylester resin can save you a lot of shop time and money compared to epoxy, and is relatively fireproof. No allergies, but it can kill your liver, and it eats unprotected styrofoam.

Are you sure you have the resources and time to get this done while it is still relevant? Money, Time, and Quality - pick any two. Burt Rutan used to offer study plans, and a kit of material sufficient to make a bookend using most of the techniques people would need to use on the aircraft. If the bookend wound up looking neat, or not, was critical data. You can't plug any numbers into your strength calculations until you have tested your own mix of materials, workmanship, and weather.

The name of the game in composites is aligning fibers, balancing stress, and minimizing resin content. Dry bagging can help with all three, and even save time once you learn it. It gives parts as good as any, without the usual wasted layers of absorbent, etc. otherwise used for vacuum bagged parts.

|

|

|

|

|

The Following User Says Thank You to Bicycle Bob For This Useful Post:

|

|

08-05-2010, 12:59 PM

08-05-2010, 12:59 PM

|

#88 (permalink)

|

|

EcoModding Apprentice

Join Date: Jun 2010

Location: mass

Posts: 181

Thanks: 4

Thanked 9 Times in 8 Posts

|

Are you familiar with wood strip canoe construction? If not you should google it.

As far as crumple zones go; home fiberglassing is rather finicky, and it's impossible to really know how it would smash up with out smashing it up (and if you made a second, it would likely act differently). I would suggest going with a welded frame, and rather flimsy 'glass body.

How do you plan on getting a windshield for this? I have some experience with glass fabrication, and it would likely cost well over a grand to have that fabricated out of regular glass, and then who knows how much more to have it laminated. As for the side windows, you would have to find a company who can temper glass, and is willing to do a small order of a custom part. I don't now if such a company exists. It would be a different story if you were making 10,000 of these.

|

|

|

|

08-05-2010, 05:05 PM

08-05-2010, 05:05 PM

|

#89 (permalink)

|

|

Master EcoModder

Join Date: Feb 2008

Location: belgium

Posts: 663

Thanks: 14

Thanked 61 Times in 44 Posts

|

perhaps for windows you could look into a one part aircraft type cupolas. these are manifactured by vacuum forming plastic over a mold. it will still be expensive but i imagine it would cost less than individual windows, wich might still be interesting to have to prevent heating, but i imagine they could be masked off and the rest be painted (also the paint could be semi transparent). a single piece would also eliminate inevitable seems and be lighter than a multy part system. given the rear slope a transparent rear roof might be more usefull than the two rear windows perhaps similar smaller parts could be used in the nose cone. alowing for simpler cheaper lights to be installed without any interruptions in the shape.

the car would than need some sort of roll cage to be safe but this could from internal window pillars and be used as an attachement point for the cuppola and the interior trim

anyway just an idea

__________________

aer·o·dy·nam·ics: the science of passing gass

*i can coast for miles and miles and miles*

|

|

|

|

08-11-2010, 05:08 PM

08-11-2010, 05:08 PM

|

#90 (permalink)

|

|

EcoModding Lurker

Join Date: Aug 2009

Location: Bulgaria

Posts: 11

Thanks: 1

Thanked 0 Times in 0 Posts

|

Hello!

Good project!

Congratulations!

|

|

|

|

|