08-18-2015, 05:19 PM

08-18-2015, 05:19 PM

|

#11 (permalink)

|

|

.........................

Join Date: Aug 2009

Location: Buckley, WA

Posts: 1,597

Thanks: 391

Thanked 488 Times in 316 Posts

|

Quote:

Originally Posted by ennored

A little reality check on the math though....

35 times the frontal area? That means it has 1/35 the drag coefficient, right?

1/35 = .029

IF the coefficient for the round shape was 1 (it must be less, but follow along), the coefficient for the airfoil is .029? Seems too low, even for a section of a chord? Someone has some numbers, right?

|

It must?

Aerohead would have to give any exact numbers from his source... But Cd of an infinitely long cylinder moving at low speeds through air is typically given as 1.2. 1/35th of that is .034. That's in the right realm for a streamlined body.

|

|

|

|

Today Today

|

|

|

|

Other popular topics in this forum...

Other popular topics in this forum...

|

|

|

|

08-18-2015, 05:39 PM

08-18-2015, 05:39 PM

|

#12 (permalink)

|

|

Master EcoWalker

Join Date: Dec 2012

Location: Nieuwegein, the Netherlands

Posts: 3,999

Thanks: 1,714

Thanked 2,248 Times in 1,456 Posts

|

Compare this to the old video Darcane posted in this link:

http://ecomodder.com/forum/showthrea...rag-25378.html

From that, at 5:49:

Quote:

|

A properly streamlined strut can be 10 times thicker than a wire and yet have no more drag.

|

Ten times. That is quite a bit less than the NACA wing shape, but the wing shape used there did not have the concave tail section.

Would that alone make for such a big difference?

__________________

2011 Honda Insight + HID, LEDs, tiny PV panel, extra brake pad return springs, neutral wheel alignment, 44/42 PSI (air), PHEV light (inop), tightened wheel nut.

lifetime FE over 0.2 Gigameter or 0.13 Megamile.

For confirmation go to people just like you.

For education go to people unlike yourself.

|

|

|

|

|

The Following User Says Thank You to RedDevil For This Useful Post:

|

|

08-19-2015, 04:58 PM

08-19-2015, 04:58 PM

|

#13 (permalink)

|

|

Master EcoModder

Join Date: Jan 2008

Location: Sanger,Texas,U.S.A.

Posts: 16,391

Thanks: 24,469

Thanked 7,409 Times in 4,800 Posts

|

cables

Quote:

Originally Posted by elhigh

That's stunning.

I remember seeing add-on fairings to make the cables on one's ultralight aircraft less of a drag, but they didn't significantly increase the frontal area, they weren't much more than stiff tapes to add to the cable.

This shows that one could replace the cables with, for instance, spars and still have no net gain while picking up lots of strength.

|

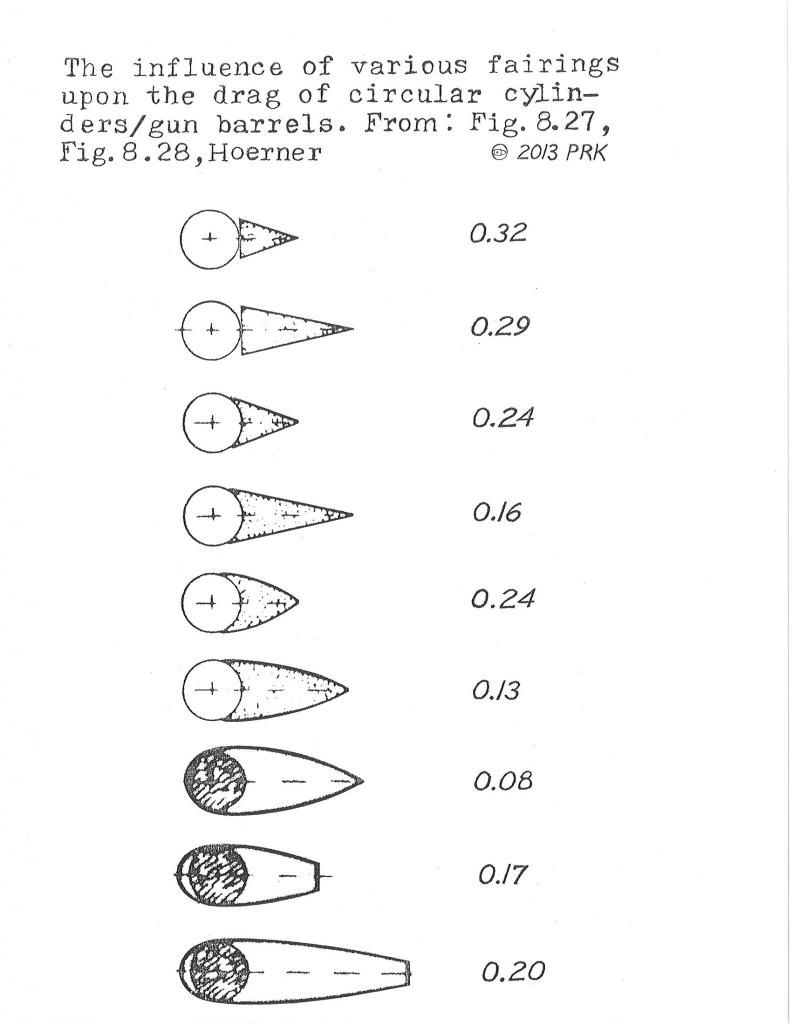

Here's a selection of shapes for fairing circular sections

__________________

Photobucket album: http://s1271.photobucket.com/albums/jj622/aerohead2/

|

|

|

|

|

The Following User Says Thank You to aerohead For This Useful Post:

|

|

08-19-2015, 05:06 PM

08-19-2015, 05:06 PM

|

#14 (permalink)

|

|

Master EcoModder

Join Date: Jan 2008

Location: Sanger,Texas,U.S.A.

Posts: 16,391

Thanks: 24,469

Thanked 7,409 Times in 4,800 Posts

|

square

Quote:

Originally Posted by veloman

Change that circle to a square and see how much smaller it'd have to be.

Either way, good lesson.

|

According to Hoerner,a square section of infinite length,crosswise in the flow would have Cd 0.20.

Korff has data on circular sections,I'll have to get that from home.

__________________

Photobucket album: http://s1271.photobucket.com/albums/jj622/aerohead2/

|

|

|

|

08-19-2015, 05:09 PM

08-19-2015, 05:09 PM

|

#15 (permalink)

|

|

Master EcoModder

Join Date: Jan 2008

Location: Sanger,Texas,U.S.A.

Posts: 16,391

Thanks: 24,469

Thanked 7,409 Times in 4,800 Posts

|

wing shape

Quote:

Originally Posted by RedDevil

Compare this to the old video Darcane posted in this link:

http://ecomodder.com/forum/showthrea...rag-25378.html

From that, at 5:49:

Ten times. That is quite a bit less than the NACA wing shape, but the wing shape used there did not have the concave tail section.

Would that alone make for such a big difference? |

Hoerner chose a laminar wing section for the comparison.It's entire boundary layer is laminar under flight conditions,leading to very low surface friction drag.

__________________

Photobucket album: http://s1271.photobucket.com/albums/jj622/aerohead2/

|

|

|

|

|

The Following User Says Thank You to aerohead For This Useful Post:

|

|

08-19-2015, 05:14 PM

08-19-2015, 05:14 PM

|

#16 (permalink)

|

|

Master EcoModder

Join Date: Jan 2008

Location: Sanger,Texas,U.S.A.

Posts: 16,391

Thanks: 24,469

Thanked 7,409 Times in 4,800 Posts

|

clarify

Quote:

Originally Posted by California98Civic

Clarify for me, by "drag" do we mean CdA and not just Cd? The airfoil has identical CdA? Seems increadible. That's not the case right? This is just identical Cd, yes?

|

These shapes are in 2-dimensional flow and their drag is based upon wetted area.

We'd use the data for wings,struts,tails,rudder,landing gear,pylons,bracing wires,some forms of auxiliary tanks.

__________________

Photobucket album: http://s1271.photobucket.com/albums/jj622/aerohead2/

|

|

|

|

08-19-2015, 05:26 PM

08-19-2015, 05:26 PM

|

#17 (permalink)

|

|

Master EcoModder

Join Date: Jan 2008

Location: Sanger,Texas,U.S.A.

Posts: 16,391

Thanks: 24,469

Thanked 7,409 Times in 4,800 Posts

|

numbers

Quote:

Originally Posted by ennored

A little reality check on the math though....

35 times the frontal area? That means it has 1/35 the drag coefficient, right?

1/35 = .029

IF the coefficient for the round shape was 1 (it must be less, but follow along), the coefficient for the airfoil is .029? Seems too low, even for a section of a chord? Someone has some numbers, right?

|

When the chord length of the airfoil section equals 167X the diameter of the wire,the drags are identical.

Bear in mind that we might be considering a length of crude circular wing support on an ultralight aircraft to a length of wing on a Lear Jet.

It's 2-dimensional flow,so not real helpful for automotive applications,however it does illustrate potentialities with respect to streamlining.

__________________

Photobucket album: http://s1271.photobucket.com/albums/jj622/aerohead2/

|

|

|

|

08-19-2015, 05:31 PM

08-19-2015, 05:31 PM

|

#18 (permalink)

|

|

Master EcoModder

Join Date: Jan 2008

Location: Sanger,Texas,U.S.A.

Posts: 16,391

Thanks: 24,469

Thanked 7,409 Times in 4,800 Posts

|

realm

Quote:

Originally Posted by darcane

It must?

Aerohead would have to give any exact numbers from his source... But Cd of an infinitely long cylinder moving at low speeds through air is typically given as 1.2. 1/35th of that is .034. That's in the right realm for a streamlined body.

|

Perhaps Abbott and von Doenhoff lists the drag table for this particular airfoil section.

Walter Korff offered a drag value for structural sections as a function of a hundred feet of length at 100-mph.We can probably reverse-engineer some values from that.

__________________

Photobucket album: http://s1271.photobucket.com/albums/jj622/aerohead2/

|

|

|

|

08-20-2015, 04:09 AM

08-20-2015, 04:09 AM

|

#19 (permalink)

|

|

Master EcoWalker

Join Date: Dec 2012

Location: Nieuwegein, the Netherlands

Posts: 3,999

Thanks: 1,714

Thanked 2,248 Times in 1,456 Posts

|

Quote:

Originally Posted by aerohead

It's 2-dimensional flow,so not real helpful for automotive applications,however it does illustrate potentialities with respect to streamlining.

|

I already have a wing shaped sleeve over my car's antenna stalk, but it is a bit out of shape.

I'll use this as a template to craft a new one from hard foam and thick alu foil.

__________________

2011 Honda Insight + HID, LEDs, tiny PV panel, extra brake pad return springs, neutral wheel alignment, 44/42 PSI (air), PHEV light (inop), tightened wheel nut.

lifetime FE over 0.2 Gigameter or 0.13 Megamile.

For confirmation go to people just like you.

For education go to people unlike yourself.

|

|

|

|

|

The Following User Says Thank You to RedDevil For This Useful Post:

|

|

08-20-2015, 04:36 AM

08-20-2015, 04:36 AM

|

#20 (permalink)

|

|

EcoModding Apprentice

Join Date: Sep 2014

Location: Alaska

Posts: 100

Thanks: 5

Thanked 65 Times in 27 Posts

|

Maybe some fairings for suspension members (at least what can be covered by a belly pan?

|

|

|

|

|