01-24-2013, 09:06 AM

01-24-2013, 09:06 AM

|

#11 (permalink)

|

|

Banned

Join Date: Oct 2009

Location: Fort Worth, Texas

Posts: 2,442

Thanks: 1,422

Thanked 737 Times in 557 Posts

|

Good start, Dave!

|

|

|

|

Today Today

|

|

|

|

Other popular topics in this forum...

Other popular topics in this forum...

|

|

|

|

01-25-2013, 11:34 PM

01-25-2013, 11:34 PM

|

#12 (permalink)

|

|

EcoModding Lurker

Join Date: Jun 2011

Location: Austin, TX

Posts: 74

Thanks: 10

Thanked 27 Times in 15 Posts

|

Side-project: air intake

As a side project I researched here, and looked at my air intake.

At its narrowest point, my air intake is a circle 1 7/8th inch in diameter, which I think is quite small and limiting in an open throttle situation. Regardless of the Cold vs. Warm intake debate going on inside my head, I drew some conclusions, and one was that this restriction had to go.

If you look at the first three attachments,you'll see the intake restriction. I saw on here a "gotts mod" to widen that restriction out to the full diameter of the hole in the side wall. However, I decided to go a different route.

I took some A/C duct material, which is a 1.5" thick fiberglass insulation sheet coated on one side with reinforced aluminum. I removed the restriction, and made an air box like would be found on a cold air intake. I left my air filter arrangement intact.

I did this non-destructively, so when there is good weather, I can do an ABACADA test with and without the obstruction.

Here's my method, theory of what I expect to see:

METHOD:

I will note the temperature, wind and road conditions, and start with a fresh tank of gas with no additives, and a well warmed up truck.

A) I'll ultragauge my consumption at 55, 65 and 75 with the original intake. I'll note the intake temperature, fuel rate, speed, and engine load.

B) Then I will remove the restriction and repeat.

A) I'll replace the intake and repeat.

C) I'll put in the box, to in theory draw in cooler air, repeat

A) I'll replace the intake and repeat.

D) I'll remove the restriction and place some drier hose on the end, drawing air from the radiator, and repeat.

A) I'll replace the intake and repeat.

I will check that each A run is consistent, and create a graph of all the data collected during the runs and publish it here, with a photograph of each configuration.

I expect to see a baseline for A runs, a slight reduction of economy with the C run, and improvements with the B and D runs.

The EPA says that on the freeway, I should get 17mpg. Not knowing their method, I'll get those baseline consumption vs speed curves. From the baseline of 17 mpg, at 68mph that's 4 gallons/hr. That means 58.8 gallons of air would be consumed in an hour at a fuel:air ratio of 1:14.7, or a gallon a minute. That sounds like a lot less than I'd imagined, so I suspect my math is wrong? Anyone in the know want to weigh in?

I'm interested in suggestions for other things to check to improve my method, and also, any other possible configurations I could add to the test? Comments/ideas strongly welcomed!

The other attachments show how bad the underside of the truck is - it's like an aerodynamic grand canyon, and I have some firm ideas of what I'd like to do about it. More on that in a future post.

|

|

|

|

01-26-2013, 07:13 PM

01-26-2013, 07:13 PM

|

#13 (permalink)

|

|

Master EcoModder

Join Date: Feb 2011

Location: Phillips, WI

Posts: 1,019

Thanks: 192

Thanked 467 Times in 287 Posts

|

Quote:

Originally Posted by plasticuser

From the baseline of 17 mpg, at 68mph that's 4 gallons/hr. That means 58.8 gallons of air would be consumed in an hour at a fuel:air ratio of 1:14.7, or a gallon a minute. That sounds like a lot less than I'd imagined, so I suspect my math is wrong? Anyone in the know want to weigh in?

|

Fuel air ratio is figured by weight. That 4 gallons of gasoline weighs about 24 lbs, so 24 X 14.7 = 353 lbs of air. Next you need the density of air, which comes from a pschrometric chart (Google is your friend to find one). Air density depends on temperature, humidity, barometric pressure, and altitude. Psychrometric charts assume the altitude is at sea level, and standard barometric pressure.

Air density can range from over 15 cubic feet per lb (hot and humid) down to less than 12 cubic feet per lb (cold). Air at 70 deg F and 50% RH has density 13.5 cubic feet per lb.

Next, multiply 353 lbs X 13.5 cubic feet per lb = 4763 cubic feet per hour = 79 cubic feet per minute. And that's your air flow.

__________________

06 Canyon: The vacuum gauge plus wheel covers helped increase summer 2015 mileage to 38.5 MPG, while summer 2016 mileage was 38.6 MPG without the wheel covers. Drove 33,021 miles 2016-2018 at 35.00 MPG.

22 Maverick: Summer 2022 burned 62.74 gallons in 3145.1 miles for 50.1 MPG. Winter 2023-2024 - 2416.7 miles, 58.66 gallons for 41 MPG.

|

|

|

|

01-26-2013, 07:50 PM

01-26-2013, 07:50 PM

|

#14 (permalink)

|

|

EcoModding Lurker

Join Date: Jun 2011

Location: Austin, TX

Posts: 74

Thanks: 10

Thanked 27 Times in 15 Posts

|

Ah, so thinking volume was a mistake, weight is correct. Thanks for explaining it to me.

I didn't have good testing conditions today. I do know that up to now my base MPG is 17. With the fan delete and the restriction removed, but no other mods, I have been getting 19.9mpg in mixed driving with a few red lights, town, some 55 and a good 65 run.

I'm hoping with the aerocap and a few other changes, I'll be up around 24-25 mpg, which means the F150 4x4 would be beating out the CX-7 for economy

Of course, I'll be working on the CX-7 too, so... If I can get that over 30mpg I'll be happy. |

|

|

|

01-27-2013, 05:14 PM

01-27-2013, 05:14 PM

|

#15 (permalink)

|

|

EcoModding Lurker

Join Date: Jun 2011

Location: Austin, TX

Posts: 74

Thanks: 10

Thanked 27 Times in 15 Posts

|

Under body panel.

I have decided the method and materials I'll use to build and attach my under body tray.

I will use tape and expanding foam to make a template/mould, then make a set of fiberglass panels that will be installed from the rear to the front, overlapping. This will make for the most lightweight and easy to install/remove system, at moderate cost/effort.

I know how to work around the exhaust, and am comfortable with that side.

I also plan to leave toom for suspension travel causing the driveshaft to move lower when the suspension unloads into a dip.

Where I am unsure is the differential. Will enclosing it or putting it out of airflow cause it to get significantly hotter? What is a normal temperature for an F150 differential after some freeway driving?

I will use my infrared thermometer to collect trip temperature data after longer drives for the next few weeks and report back, but any insight would be helpful.

|

|

|

|

01-27-2013, 06:23 PM

01-27-2013, 06:23 PM

|

#16 (permalink)

|

|

T-100 Road Warrior

Join Date: Apr 2008

Location: The Woodlands, TX

Posts: 1,921

Thanks: 3,502

Thanked 1,395 Times in 968 Posts

|

Quote:

Originally Posted by plasticuser

Where I am unsure is the differential. Will enclosing it or putting it out of airflow cause it to get significantly hotter? What is a normal temperature for an F150 differential after some freeway driving?

I will use my infrared thermometer to collect trip temperature data after longer drives for the next few weeks and report back, but any insight would be helpful.

|

Yer differential will git warmer in temp when it's enclosed with a belly pan. Temperature will depend on the loading (towing/bed load). Best thing to do is run a thermometer probe on the differential and measure yer temps and git a baseline before you install yer belly pans. After you install yer belly pans, you'll be able to tell how warm yer differential will git up to and if you'll be comfortable with those temps or not. Just don't go blind and not use some sort of continuous temp monitoring setup.

__________________

Dark Aero-The world's first aerodynamic single wheel boat tail!

|

|

|

|

01-28-2013, 09:37 AM

01-28-2013, 09:37 AM

|

#17 (permalink)

|

|

Banned

Join Date: Oct 2009

Location: Fort Worth, Texas

Posts: 2,442

Thanks: 1,422

Thanked 737 Times in 557 Posts

|

Something that came up recently with my pickup. At 7,900-lbs, and two destroyed tires, I had to order a rollback wrecker. We had to find attachment points to winch the thing up the bed. So, be sure to keep this in mind with any bellypan.

|

|

|

|

01-28-2013, 02:33 PM

01-28-2013, 02:33 PM

|

#18 (permalink)

|

|

EcoModding Lurker

Join Date: Jun 2011

Location: Austin, TX

Posts: 74

Thanks: 10

Thanked 27 Times in 15 Posts

|

*nods*

I can see how that would be a problem. Also, getting under there if it was dropped the height of the tires would be an issue too. I will look at the rear attachment points and make a plan.

Good call. Thank you.

That's a nice Airstream you have there. Single axle at that length, is it a 50's pre-torsion axle one?

__________________

|

|

|

|

01-28-2013, 07:18 PM

01-28-2013, 07:18 PM

|

#19 (permalink)

|

|

Batman Junior

Join Date: Nov 2007

Location: 1000 Islands, Ontario, Canada

Posts: 22,541

Thanks: 4,085

Thanked 6,989 Times in 3,619 Posts

|

Late to the party, but subscribed and watching with interest.

And thumbs up for the "open source" and willingness to share approach.

Plans to A-B-A test the cap when it's finished?

|

|

|

|

01-28-2013, 08:28 PM

01-28-2013, 08:28 PM

|

#20 (permalink)

|

|

Bring on the turd polish!

Join Date: Feb 2010

Location: maine

Posts: 45

Pablo - '86 Toyota Pickup 1 Ton, 22RE, W56 trans, 4.300 diff. Pickups 90 day: 25.68 mpg (US) Red Brighton - '98 Subaru Legacy Wagon Brighton 90 day: 32.3 mpg (US) Rust Victim - '00 Toyota Tacoma SR5, 2WD, 5 speed manual, 2.4l, Extracab. Last 3: 29.68 mpg (US)

Thanks: 8

Thanked 18 Times in 10 Posts

|

I'm still designing a cap for Pablo's bed. It's a 7' x 5 1/2' flatbed with stake pockets. I'm also going to need full side skirts. It's just a little cold out there to get it done tonight.

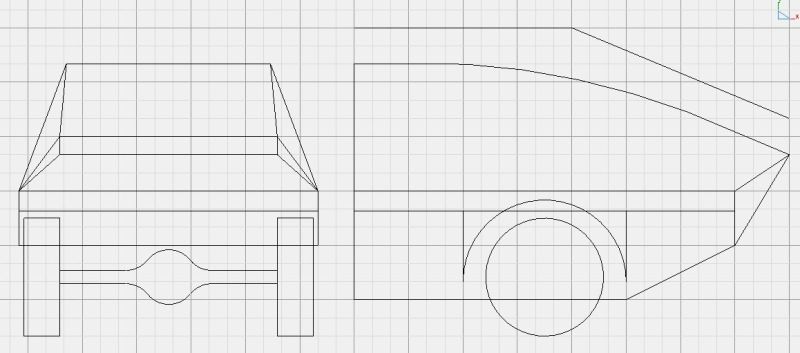

I drew the horizontal line 4' straight level back from the front of the cap, then angled it down to end 8" above bed level 12" back from the back end of the bed. Then I did a spline curve from the front to the midpoint of each of the lines, and then to the back end of the sloped line. I think this will give me room for a decent side door. The sides will slope so that it's 45" wide (cab top width) in front and 48" wide in back. That will involve torturing the ply on the sides slightly, but it's within doable limits.

My plan is to cut two templates out of scrap and bend a properly trimmed 4x8 sheet over them, set the side pieces in place and mark them to that curve on their angles, and then put it together with some interior framing. I'm imagining a large hatch in the roof piece to make loading easy, but I haven't worked out those details. As I said, there'd also be a side door.

Last edited by mackerel; 01-28-2013 at 08:49 PM..

|

|

|

|

|

The Following User Says Thank You to mackerel For This Useful Post:

|

|

|