01-06-2016, 11:49 AM

01-06-2016, 11:49 AM

|

#211 (permalink)

|

|

T-100 Road Warrior

Join Date: Apr 2008

Location: The Woodlands, TX

Posts: 1,921

Thanks: 3,502

Thanked 1,395 Times in 968 Posts

|

I'm surprised you didn't try some Coroplast instead of the sheet metal.

__________________

Dark Aero-The world's first aerodynamic single wheel boat tail!

|

|

|

|

Today Today

|

|

|

|

Other popular topics in this forum...

Other popular topics in this forum...

|

|

|

|

01-06-2016, 01:32 PM

01-06-2016, 01:32 PM

|

#212 (permalink)

|

|

Master EcoModder

Join Date: Aug 2012

Location: northwest of normal

Posts: 29,421

Thanks: 8,369

Thanked 9,128 Times in 7,537 Posts

|

I don't like to work with fiberglass, but I'm curious where the process fell apart. There was a rough form at permalink #201. Was it smoothed? Did you apply any cloth and resin?

The new nose: One piece of... aluminum? galvanized steel?

|

|

|

|

01-06-2016, 01:48 PM

01-06-2016, 01:48 PM

|

#213 (permalink)

|

|

(:

Join Date: Jan 2008

Location: up north

Posts: 12,762

Thanks: 1,585

Thanked 3,558 Times in 2,220 Posts

|

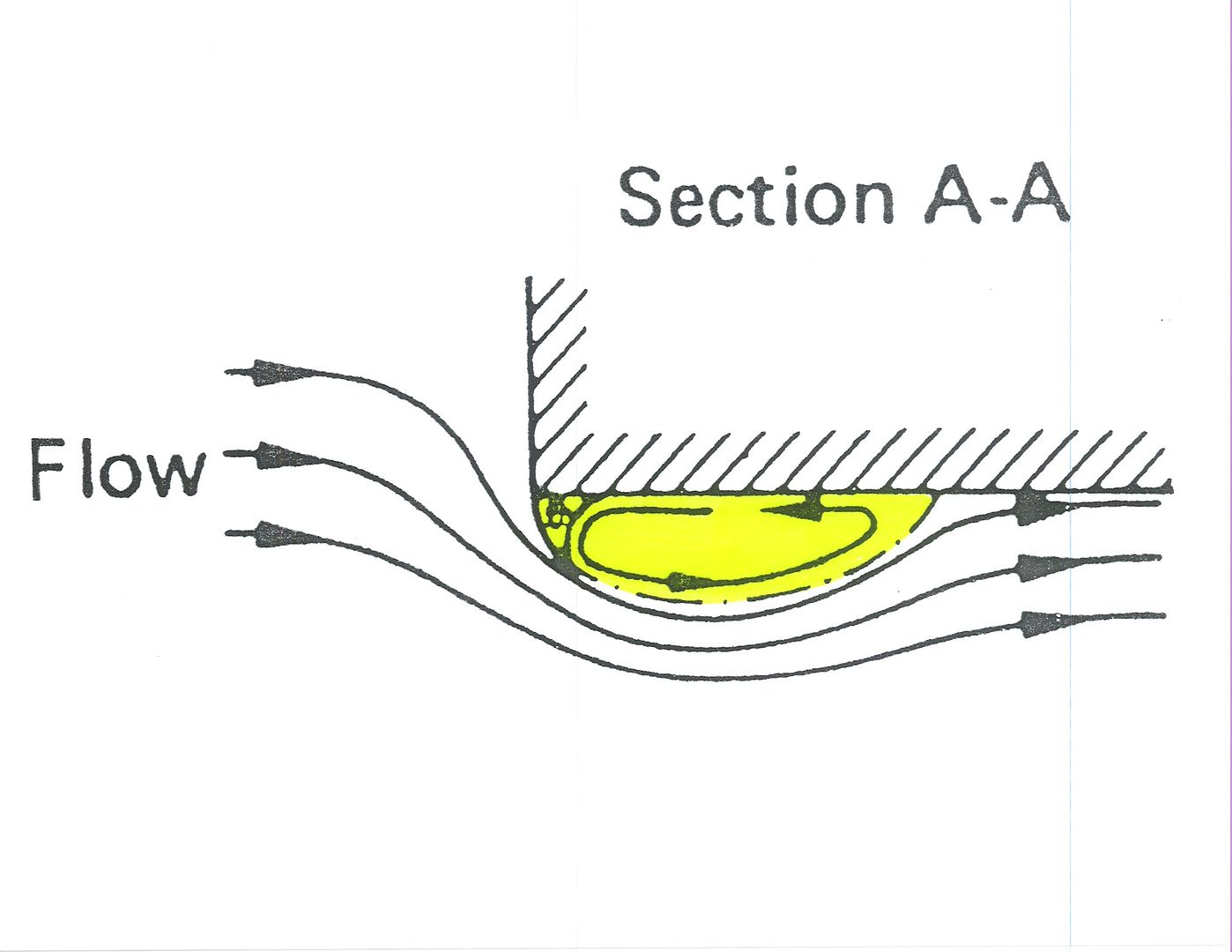

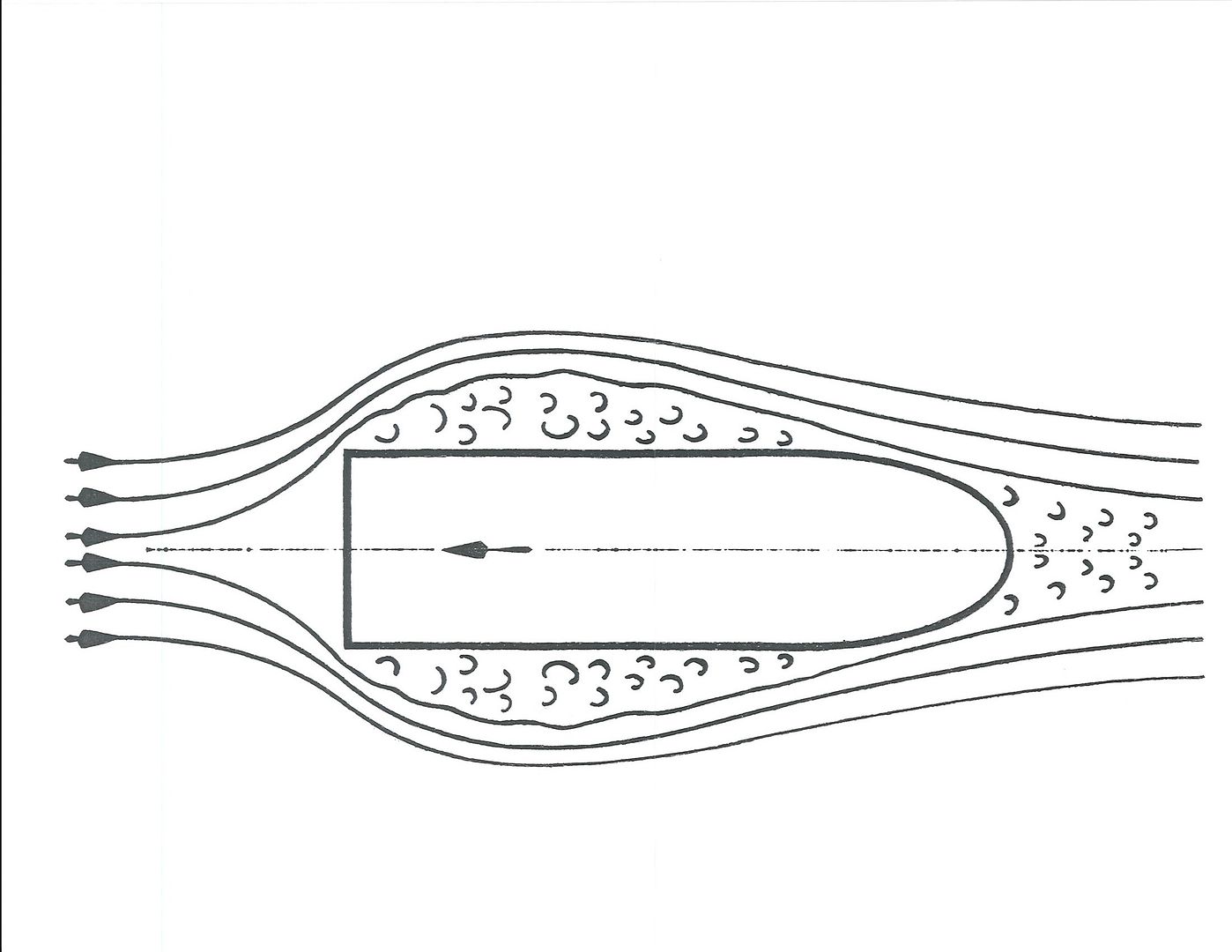

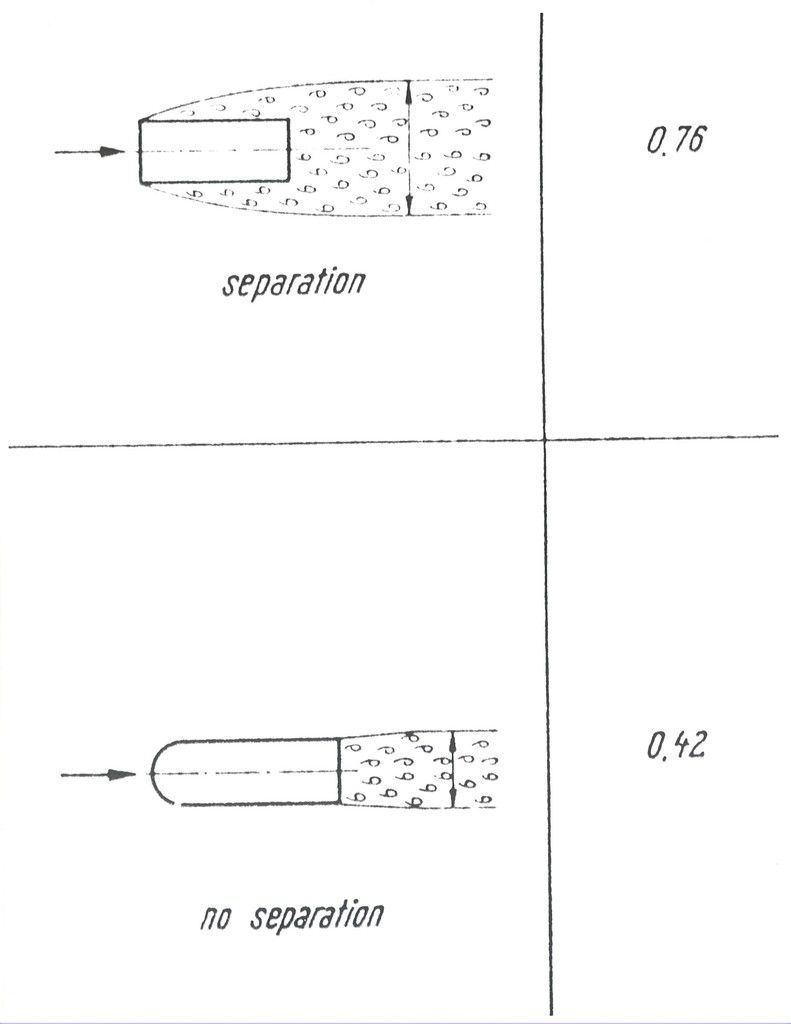

Whatever method of fabrication you wind up with, I suggest nice generous radii on all leading surface transitions. And pay as much attention to the rear of the machine as the front, if not moreso.

|

|

|

|

|

The Following 2 Users Say Thank You to Frank Lee For This Useful Post:

|

|

01-06-2016, 03:51 PM

01-06-2016, 03:51 PM

|

#214 (permalink)

|

|

EcoModding Apprentice

Join Date: Jul 2015

Location: Barcelona

Posts: 104

Thanks: 75

Thanked 63 Times in 37 Posts

|

Quote:

Originally Posted by BamZipPow

I'm surprised you didn't try some Coroplast instead of the sheet metal.  |

Well, haven't worked with coroplast before, and i didn't even thought on it.

But i'm interested to know how to work with it if is useful for other parts of the car.

Quote:

I don't like to work with fiberglass, but I'm curious where the process fell apart. There was a rough form at permalink #201. Was it smoothed? Did you apply any cloth and resin?

The new nose: One piece of... aluminum? galvanized steel?

|

It wasn't for the smoothness of the mold, it was for time reasons ( the race season starts on January 12 ) and because the mold wasn't perfect  , in fact far from it, it was asymmetrical and kind of " dented".

So after losing so much time with the foam, It annoyed me, i got angry and i decided that doing it with metal was the best option.

Galvanized steel 0.7 mm of thickness.

Quote:

|

Whatever method of fabrication you wind up with, I suggest nice generous radii on all leading surface transitions. And pay as much attention to the rear of the machine as the front, if not moreso.

|

The Rear is the Next Project!

i think that no one liked the nose

on January 17 i will race the gravity racer, i will record the race and use dashware, what do you think, should i use the wool test on the race to see the aero effects of the nose? |

|

|

|

|

The Following User Says Thank You to orengomotors For This Useful Post:

|

|

01-06-2016, 06:04 PM

01-06-2016, 06:04 PM

|

#215 (permalink)

|

|

Master EcoModder

Join Date: Jan 2008

Location: Sanger,Texas,U.S.A.

Posts: 16,534

Thanks: 24,520

Thanked 7,438 Times in 4,818 Posts

|

tufts

I think that you're going to see a bunch of vorticity due to the hard edges.

I'm with Frank,recommending radius'd edges everywhere.

You're kinda 1/2-scale,so maybe a 40mm radius minimum.

__________________

Photobucket album: http://s1271.photobucket.com/albums/jj622/aerohead2/

|

|

|

|

|

The Following 2 Users Say Thank You to aerohead For This Useful Post:

|

|

01-06-2016, 07:17 PM

01-06-2016, 07:17 PM

|

#216 (permalink)

|

|

Master EcoModder

Join Date: Aug 2012

Location: northwest of normal

Posts: 29,421

Thanks: 8,369

Thanked 9,128 Times in 7,537 Posts

|

Quote:

i think that no one liked the nose

|

I never said that. I'm glad you gave up on that marbelized foam thing. Fiberglass molds need a high surface finish.

Leave it to Frank Lee to say "Everything you do is wrong!" The angled edges above the suspension might need a little eyebrow. The objections are to the edges across the flow. Look for the solutions where trailer owners have put half-round on their boxes.

Quote:

Well, haven't worked with coroplast before, and i didn't even thought on it.

But i'm interested to know how to work with it if is useful for other parts of the car.

|

Coroplast is, in the words of Lt. Niedermeyer, "weak and worthless".*

Use prefinished sheet material (galvanizing counts), save hours compared to finishing a raw fiberglass part. Here are solutions to seaming along and across radii. Curved edges result in pseudo-compound curved surfaces.

Most builder run the gores lengthwise, the 1947 Roswell goes against the grain.

*Coroplast with welding rod slipped into the flutes might work.

|

|

|

|

|

The Following User Says Thank You to freebeard For This Useful Post:

|

|

01-06-2016, 07:28 PM

01-06-2016, 07:28 PM

|

#217 (permalink)

|

|

(:

Join Date: Jan 2008

Location: up north

Posts: 12,762

Thanks: 1,585

Thanked 3,558 Times in 2,220 Posts

|

I said no such thing.

Besides, the only person that has to be happy with it is him. |

|

|

|

01-07-2016, 03:12 AM

01-07-2016, 03:12 AM

|

#218 (permalink)

|

|

Master EcoModder

Join Date: Aug 2012

Location: northwest of normal

Posts: 29,421

Thanks: 8,369

Thanked 9,128 Times in 7,537 Posts

|

The cowl areas has a lot of constraints. Clearing the suspension and all.

It's not so far off from this. A curved plexiglass low windscreen would give any vorticular detachment a place to go die. The sharp front corners are unfortunate. Simply cap them with a forward facing bullets. Or a 1/3th scale bull horn. |

|

|

|

01-07-2016, 04:37 AM

01-07-2016, 04:37 AM

|

#219 (permalink)

|

|

Master EcoModder

Join Date: Feb 2009

Location: France - Paris

Posts: 762

Thanks: 188

Thanked 33 Times in 30 Posts

|

What about moving front struts inboard ?

Or at least add a fairing on them.

I assume you will also do the back of the vehicle ?

I am looking forward to see numbers on how that translates on the track !

__________________

|

|

|

|

01-07-2016, 06:02 PM

01-07-2016, 06:02 PM

|

#220 (permalink)

|

|

...beats walking...

Join Date: Jul 2009

Location: .

Posts: 6,190

Thanks: 179

Thanked 1,525 Times in 1,126 Posts

|

I LIKE the "welding rod-in-coroplast" stiffening idea!

|

|

|

|

|