01-09-2016, 12:54 PM

01-09-2016, 12:54 PM

|

#231 (permalink)

|

|

Master EcoModder

Join Date: Jan 2008

Location: Sanger,Texas,U.S.A.

Posts: 16,503

Thanks: 24,517

Thanked 7,436 Times in 4,817 Posts

|

how

Quote:

Originally Posted by orengomotors

Ok, how can i do the radius? with a tube 40m radius and a hammer? any other ideas?

Thank you

|

A sheetmetal fabricator would have a slip-roller which they'd use to roll the radius into sheetmetal.

Short of that,you might find pre-fabricated flue pipe for a gas-fired water heater of appropriate diameter,which could be cut down to create the soft edges.

The inside surface of PVC pipe can also be used as a mold to layup fiberglass radius sections.I did this for a trailer body."joggles" can be cast into mating edges of the part by taping chipboard strips inside the mold with aluminum tape.

Three coats of carnauba wax will get a clean release from the mold.

__________________

Photobucket album: http://s1271.photobucket.com/albums/jj622/aerohead2/

|

|

|

|

|

The Following User Says Thank You to aerohead For This Useful Post:

|

|

Today Today

|

|

|

|

Other popular topics in this forum...

Other popular topics in this forum...

|

|

|

|

01-09-2016, 01:20 PM

01-09-2016, 01:20 PM

|

#232 (permalink)

|

|

Master EcoModder

Join Date: Aug 2012

Location: northwest of normal

Posts: 29,337

Thanks: 8,345

Thanked 9,109 Times in 7,522 Posts

|

Quote:

|

What edges are you referring?

|

The blue and green edges are easily dealt with by adding a block styrofoam bumper and rounding it appropriately.

The red edges are the ones I referred to. Since the top face has a incline for the oncoming air, vortices will shed down and outward, especially in cross winds.

http://ecomodder.com/forum/showthread.php/canard-bluff-bodied-box-33231-2.html#post502508

http://ecomodder.com/forum/showthread.php/canard-bluff-bodied-box-33231-2.html#post502508

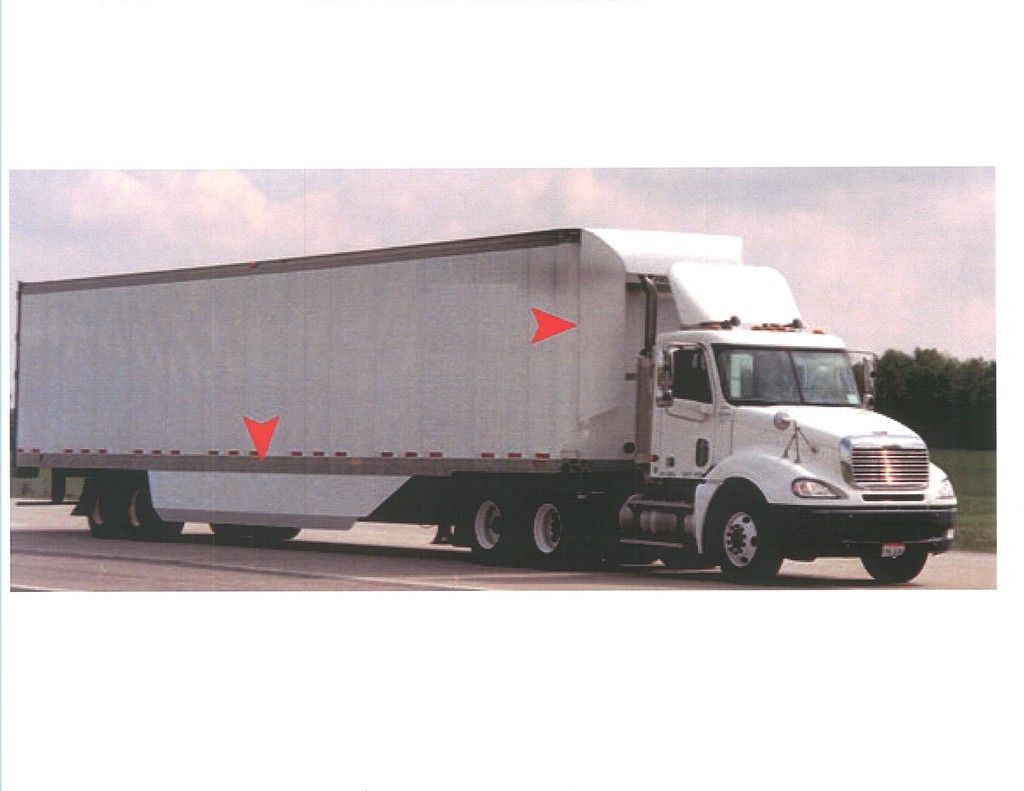

Here's a fix for truck vans that aerohead posted in another thread. Since the nose slopes the red edges could receive a treatment where the radius is flush with the top face and overhangs the suspension bits. It could die into the outward curve behind the wheel. Essentially, the van side becomes you nose top and the van nose becomes your side, with the styrofoam block widened as necessary. The A-arms are [always] an aerodynamic mess anyway, shrouding them couldn't hurt.

|

|

|

|

|

The Following User Says Thank You to freebeard For This Useful Post:

|

|

01-10-2016, 04:50 PM

01-10-2016, 04:50 PM

|

#233 (permalink)

|

|

EcoModding Apprentice

Join Date: Jul 2015

Location: Barcelona

Posts: 104

Thanks: 75

Thanked 63 Times in 37 Posts

|

Quote:

Originally Posted by aerohead

A sheetmetal fabricator would have a slip-roller which they'd use to roll the radius into sheetmetal.

Short of that,you might find pre-fabricated flue pipe for a gas-fired water heater of appropriate diameter,which could be cut down to create the soft edges.

The inside surface of PVC pipe can also be used as a mold to layup fiberglass radius sections.I did this for a trailer body."joggles" can be cast into mating edges of the part by taping chipboard strips inside the mold with aluminum tape.

Three coats of carnauba wax will get a clean release from the mold.

|

I have an old slip-roller tool, I'll try that! |

|

|

|

01-10-2016, 04:55 PM

01-10-2016, 04:55 PM

|

#234 (permalink)

|

|

EcoModding Apprentice

Join Date: Jul 2015

Location: Barcelona

Posts: 104

Thanks: 75

Thanked 63 Times in 37 Posts

|

Quote:

Originally Posted by Grant-53

See the recumbent.com site for the HPV design software by Wayne Shook. Some of the most efficient shell designs come from Delft University.

If you can get steel piano wire it may be less expensive than welding rod to use as a stiffener for the coroplast. Check their website for the latest sizes and products including hex core panels.

|

Are you referring this? The Recumbent Bicycle and Human Powered Vehicle Information Center

It says: "Once the fairing is created ribs can be exported and printed to allow an easy creation of the actual shell using the strips over ribs technique."

Maybe the ribs could be exported to .dxf and i could cut it with the laser cutter. It would be great to finish the bodywork!

Last edited by orengomotors; 01-10-2016 at 05:06 PM..

|

|

|

|

01-10-2016, 05:08 PM

01-10-2016, 05:08 PM

|

#235 (permalink)

|

|

EcoModding Apprentice

Join Date: Jul 2015

Location: Barcelona

Posts: 104

Thanks: 75

Thanked 63 Times in 37 Posts

|

Quote:

Originally Posted by freebeard

The blue and green edges are easily dealt with by adding a block styrofoam bumper and rounding it appropriately.

|

Ok, i will star first by rounding the blue and green.

I'll post the results soon! |

|

|

|

01-10-2016, 05:51 PM

01-10-2016, 05:51 PM

|

#236 (permalink)

|

|

Master EcoModder

Join Date: Feb 2010

Location: Elmira, NY

Posts: 1,794

Thanks: 320

Thanked 361 Times in 300 Posts

|

Yes, that is the software package.

|

|

|

|

01-10-2016, 10:15 PM

01-10-2016, 10:15 PM

|

#237 (permalink)

|

|

Master EcoModder

Join Date: Aug 2012

Location: northwest of normal

Posts: 29,337

Thanks: 8,345

Thanked 9,109 Times in 7,522 Posts

|

If you do the red edges first, that may affect the width of the nose piece. You hadn't said you have a roller. Use that. Just add a 2nd layer on top.

|

|

|

|

02-08-2016, 11:30 AM

02-08-2016, 11:30 AM

|

#238 (permalink)

|

|

EcoModding Apprentice

Join Date: Jul 2015

Location: Barcelona

Posts: 104

Thanks: 75

Thanked 63 Times in 37 Posts

|

|

|

|

|

02-08-2016, 02:25 PM

02-08-2016, 02:25 PM

|

#239 (permalink)

|

|

Master EcoModder

Join Date: Aug 2012

Location: northwest of normal

Posts: 29,337

Thanks: 8,345

Thanked 9,109 Times in 7,522 Posts

|

A new direction? IMHO the rounded bottom wouldn't be optimal. Lakester class belly tanks are that way because they start with airplane parts.

|

|

|

|

02-09-2016, 04:16 PM

02-09-2016, 04:16 PM

|

#240 (permalink)

|

|

Master EcoModder

Join Date: Jan 2008

Location: Sanger,Texas,U.S.A.

Posts: 16,503

Thanks: 24,517

Thanked 7,436 Times in 4,817 Posts

|

nose/tail

Quote:

Originally Posted by orengomotors

|

Technically,there's no good reason for the nose to allow any air under the car.

The turbulence from the wheels,axles,and roll cage will severely compromise the performance of the boat-tail.

Baron Reinhard Koenig-Fachsenfeld chopped off the boat tail of a 1920s Mercedes-Benz Gran Prix racer and 'improved' it's performance for a win.

__________________

Photobucket album: http://s1271.photobucket.com/albums/jj622/aerohead2/

|

|

|

|

|