11-03-2014, 10:57 PM

11-03-2014, 10:57 PM

|

#1 (permalink)

|

|

EcoModding Apprentice

Join Date: May 2011

Location: Oregon

Posts: 106

Thanks: 0

Thanked 26 Times in 22 Posts

|

Plan for my cargo trailer

I have a 6x12 enclosed trailer with standard (not ramp) rear door. The front surface is rounded but the junction between sides and top (or front and top or rear and top) is 90 degrees. The top is pretty much flat.

It has really killed the mileage I get with my Ram 1500, Pentastar engine and 8-speed transmission. So I'm thinking of some mods.

On the sides at the top I was thinking of cutting a piece of 4" pvc pipe lengthwise and attaching each half-pipe along the edge (on the sides, so it merges smoothly with the top surface). This would give some radius but I don't know if that is enough to do any good.

On the front, at that edge, I cannot do it so easily as it is curved. So instead I was thinking of putting a lip up there to separate the flow going over the top with that going around the sides, more or less like the ones I've seen pictures of used on air dams. Maybe 6" wide?

At the rear I am thinking either VGs, or a tapered box, or VGs on a tapered box. I'm thinking acrylic for the box to avoid having to make a cut-out for the tail lights and any reflectors. Extending back maybe 2 feet just to keep it reasonable, which means if it's 12 degrees it will have come in about 5 inches all around (not sure if it's worth doing on the bottom). I should be able to mount on the door hinges so it will swing out of the way when the door is opened. It would have a sharp transition and I wonder about that.

Then I think, "why bother?" I should just drive 5mph slower and avoid all that work.

__________________

|

|

|

|

Today Today

|

|

|

|

Other popular topics in this forum...

Other popular topics in this forum...

|

|

|

|

11-04-2014, 08:33 AM

11-04-2014, 08:33 AM

|

#2 (permalink)

|

|

Not Doug

Join Date: Jun 2012

Location: Show Low, AZ

Posts: 12,313

Thanks: 7,313

Thanked 2,246 Times in 1,733 Posts

|

Can you post images? That should be able to help us understand your situation better. Thanks!

|

|

|

|

11-04-2014, 09:35 AM

11-04-2014, 09:35 AM

|

#3 (permalink)

|

|

Batman Junior

Join Date: Nov 2007

Location: 1000 Islands, Ontario, Canada

Posts: 22,541

Thanks: 4,085

Thanked 6,989 Times in 3,619 Posts

|

If the leading edges (sides & top) are radiused, then proceed directly to the tapering addition at the rear of the trailer.

I'd make the rear extension as long as possible. The smaller the cross-sectional area where you truncate (assuming you retain attached flow), the better your results.

Quote:

Then I think, "why bother?" I should just drive 5mph slower and avoid all that work.

|

Or do both, and double your savings.  |

|

|

|

11-04-2014, 11:28 AM

11-04-2014, 11:28 AM

|

#4 (permalink)

|

|

EcoModding Apprentice

Join Date: May 2011

Location: Oregon

Posts: 106

Thanks: 0

Thanked 26 Times in 22 Posts

|

Sorry, I should have posted photos in the first place.

Hmmm, for some reason I can't upload the picture of the front to photobucket even though I can look at it on my own computer. You'll have to take my word that the front curves around to the sides, but there is no radius anywhere on the top surface.

Here is what I mean about adding a radius to that top edge:

__________________

Last edited by PaulB2; 11-04-2014 at 11:36 AM..

|

|

|

|

11-04-2014, 12:38 PM

11-04-2014, 12:38 PM

|

#5 (permalink)

|

|

Master EcoModder

Join Date: Aug 2012

Location: northwest of normal

Posts: 29,407

Thanks: 8,364

Thanked 9,123 Times in 7,533 Posts

|

The front top edge would benefit.

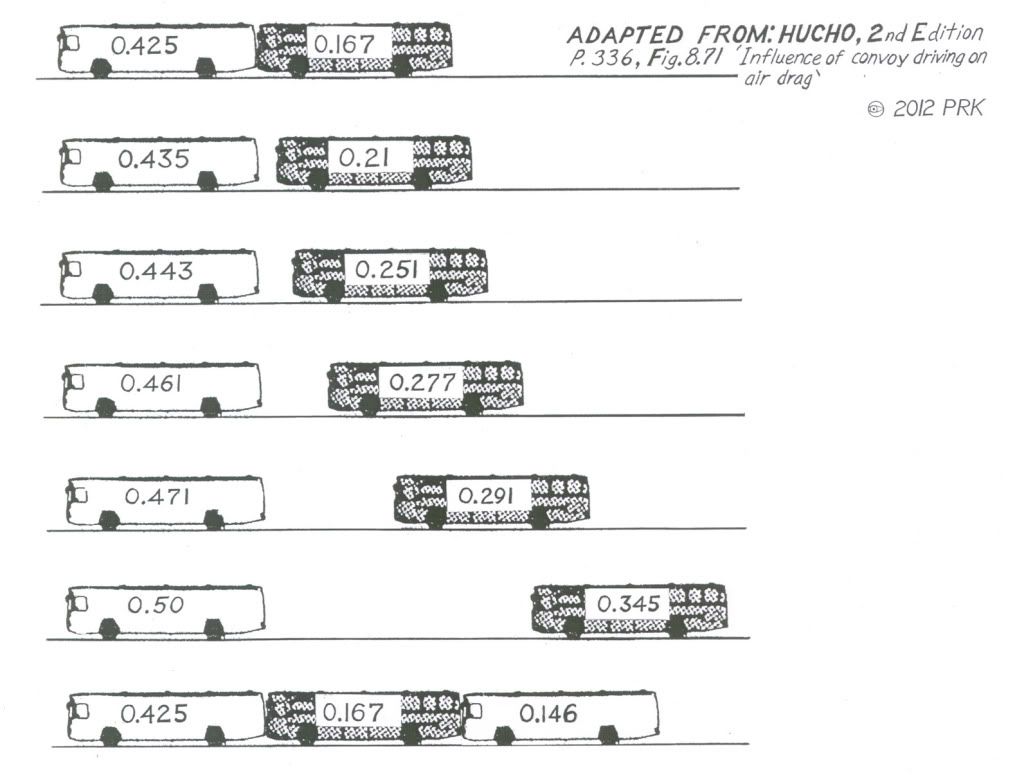

Past a certain length, the square edges on the sides don't matter, except to cross-winds. Here are your options. Your proposal is labeled 'fairing'. The 20% loss in the inter-vehicle gap may be more than 20%. Does your Ram have an open bed, tonneau, or aerocap?

|

|

|

|

11-04-2014, 12:59 PM

11-04-2014, 12:59 PM

|

#6 (permalink)

|

|

Corporate imperialist

Join Date: Jul 2011

Location: NewMexico (USA)

Posts: 11,312

Thanks: 273

Thanked 3,584 Times in 2,845 Posts

|

I say try some side skirts and at least some rear strakes.

Most of the big rigs that can't use foldable boat tail for some reason are now using the strakes.

__________________

1984 chevy suburban, custom made 6.5L diesel turbocharged with a Garrett T76 and Holset HE351VE, 22:1 compression 13psi of intercooled boost.

1989 firebird mostly stock. Aside from the 6-speed manual trans, corvette gen 5 front brakes, 1LE drive shaft, 4th Gen disc brake fbody rear end.

2011 leaf SL, white, portable 240v CHAdeMO, trailer hitch, new batt as of 2014.

|

|

|

|

11-04-2014, 02:57 PM

11-04-2014, 02:57 PM

|

#7 (permalink)

|

|

Master EcoModder

Join Date: Jan 2008

Location: Sanger,Texas,U.S.A.

Posts: 16,534

Thanks: 24,520

Thanked 7,436 Times in 4,817 Posts

|

trailer

Quote:

Originally Posted by PaulB2

I have a 6x12 enclosed trailer with standard (not ramp) rear door. The front surface is rounded but the junction between sides and top (or front and top or rear and top) is 90 degrees. The top is pretty much flat.

It has really killed the mileage I get with my Ram 1500, Pentastar engine and 8-speed transmission. So I'm thinking of some mods.

On the sides at the top I was thinking of cutting a piece of 4" pvc pipe lengthwise and attaching each half-pipe along the edge (on the sides, so it merges smoothly with the top surface). This would give some radius but I don't know if that is enough to do any good.

On the front, at that edge, I cannot do it so easily as it is curved. So instead I was thinking of putting a lip up there to separate the flow going over the top with that going around the sides, more or less like the ones I've seen pictures of used on air dams. Maybe 6" wide?

At the rear I am thinking either VGs, or a tapered box, or VGs on a tapered box. I'm thinking acrylic for the box to avoid having to make a cut-out for the tail lights and any reflectors. Extending back maybe 2 feet just to keep it reasonable, which means if it's 12 degrees it will have come in about 5 inches all around (not sure if it's worth doing on the bottom). I should be able to mount on the door hinges so it will swing out of the way when the door is opened. It would have a sharp transition and I wonder about that.

Then I think, "why bother?" I should just drive 5mph slower and avoid all that work.  |

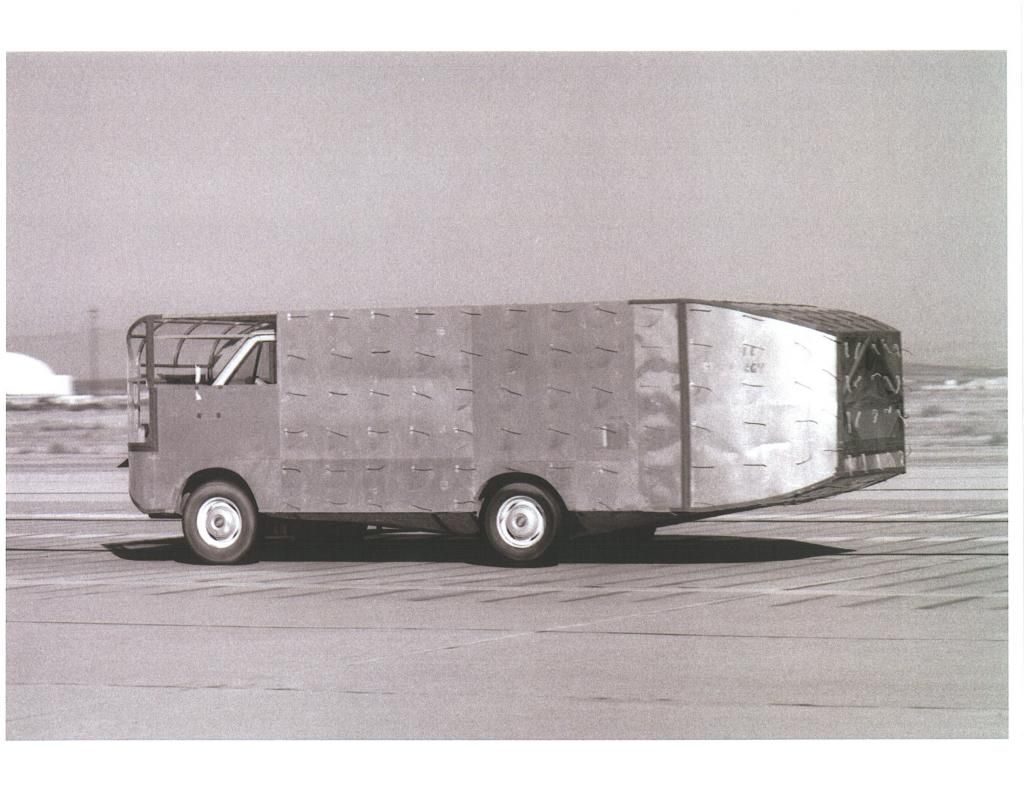

*If you had a topper on the RAM,and something to fill the gap,you could take all the air off the front of the trailer,like the zero-clearance buses in a NASCAR-style draft

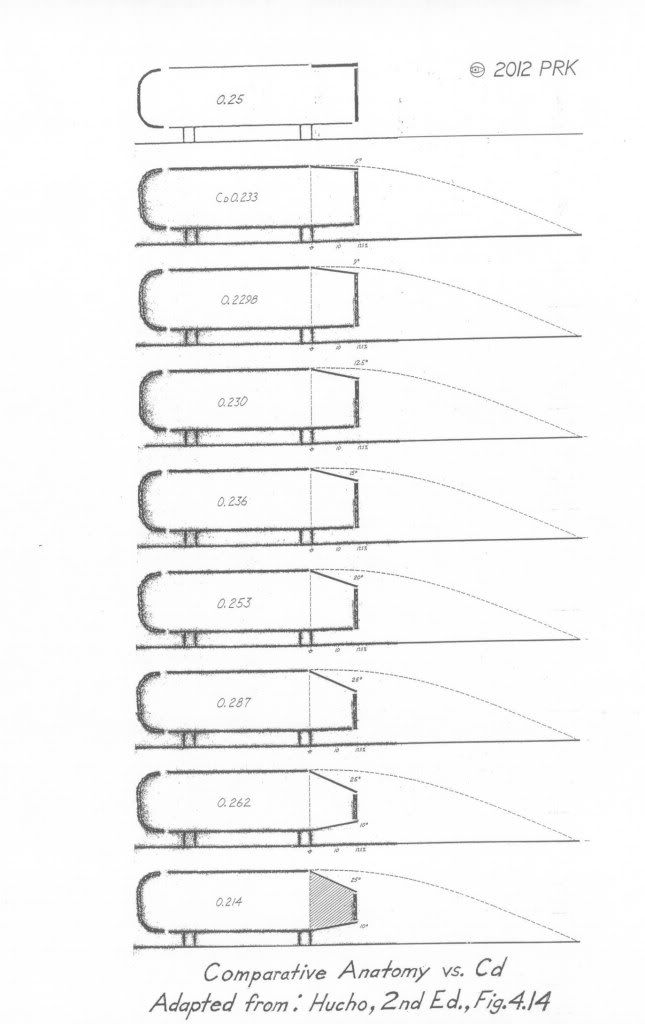

*For the tail cone,a design has been tested with 25-degree top,10-degree sides,and 10-degree bottom diffuser,which showed lowest for all of the group tested

*All edges are sharp,as you already have and would be about as simple to fabricate as anything you might want to take on.

*While your upper surfaces aren't ideal,NASA was able to get to Cd 0.238 with their sharp-edged van

*In lieu of a tapered boat tail you could also consider an aerodynamic box-cavity.It would be a compromise with respect to performance,but would be simple,lightweight,easy to fabricate,and you wouldn't have to mess with your lighting.I don't have an image but there's a bunch on GOOGLE Images

here's a link

http://patentimages.storage.googleap...101-D00003.png

__________________

Photobucket album: http://s1271.photobucket.com/albums/jj622/aerohead2/

Last edited by aerohead; 11-04-2014 at 03:00 PM..

Reason: correct angle

|

|

|

|

|

The Following User Says Thank You to aerohead For This Useful Post:

|

|

11-04-2014, 06:20 PM

11-04-2014, 06:20 PM

|

#8 (permalink)

|

|

EcoModding Apprentice

Join Date: May 2011

Location: Oregon

Posts: 106

Thanks: 0

Thanked 26 Times in 22 Posts

|

Quote:

|

For the tail cone,a design has been tested with 25-degree top,10-degree sides,and 10-degree bottom diffuser,which showed lowest for all of the group tested

|

I had seen that illustration in other threads, but was not aware of the 10 degree sides and didn't notice that the last item was the lowest Cd either (I was concentrating on the 3rd and 4th from the top). I also do not see what is different between the last two items. What does the cross-hatching represent?

I think the taper on a boat tail would be pretty easy (no need to compromise with that square box), but getting the transition smooth like the NASA van would not be. Hope that doesn't hurt too much. Also I have a feeling that adding the bottom part of the cone is not worth too much without also having a belly pan on the trailer. Or maybe a dam at the front of the trailer and skirts on the side, to exclude air? A belly pan would be pretty easy on this trailer, just hang some plastic roofing under there. Skirts and dam would not be that tough either, provided I find some material that can take a beating (I was thinking of plastic baseboard molding).

Right now in the Ram I have a home-made half-tonneau. I realize the gap is a big problem and probably is a lot of work to fix, which is why I'm thinking of just winging it with a lip on top to separate the flow for now. A vortex trap or two might not be too difficult, for what it's worth; but I'm guessing they don't help unless the Ram has a high cap.

__________________

|

|

|

|

11-04-2014, 09:59 PM

11-04-2014, 09:59 PM

|

#9 (permalink)

|

|

Master EcoModder

Join Date: Aug 2012

Location: northwest of normal

Posts: 29,407

Thanks: 8,364

Thanked 9,123 Times in 7,533 Posts

|

Base on the jump from 0.262 to 0.214 Cd, I'd bet that the gray shading represents plan taper and the others are flat-sided.

The vortex traps are designed to prevent air cross-migrating under cross-wind conditions, so—yup wouldn't help.

If you curve the boattail panels instead having them flat, it would be lighter and/or stronger.

|

|

|

|

11-05-2014, 11:26 AM

11-05-2014, 11:26 AM

|

#10 (permalink)

|

|

EcoModding Apprentice

Join Date: May 2011

Location: Oregon

Posts: 106

Thanks: 0

Thanked 26 Times in 22 Posts

|

Quote:

|

I'd bet that the gray shading represents plan taper and the others are flat-sided.

|

You mean taper as viewed from above? I think you are right, because the top pic has no taper anywhere, and the next one (and following) investigates the change of a single factor, the top angle. I think so, anyway. Maybe aerohead can confirm.

Good point about curving the panels, and it also reduces the transition problem. I have an idea how to do that, so I will try to put at least a small curve into them.

__________________

|

|

|

|

|

The Following User Says Thank You to PaulB2 For This Useful Post:

|

|

|