06-29-2015, 04:30 PM

06-29-2015, 04:30 PM

|

#31 (permalink)

|

|

Corporate imperialist

Join Date: Jul 2011

Location: NewMexico (USA)

Posts: 11,312

Thanks: 273

Thanked 3,584 Times in 2,845 Posts

|

The old carbureted engines used a heat shroud around the 1 or 2 of the exhaust manifold exhaust primaries to give the carb some warm air almost immediately after startup.

This was just mostly so it would idle and not stall constantly right after a good cold startup.

The exhaust manifolds get real hot but its not very easy to get a high volume of really hot air off them.

__________________

1984 chevy suburban, custom made 6.5L diesel turbocharged with a Garrett T76 and Holset HE351VE, 22:1 compression 13psi of intercooled boost.

1989 firebird mostly stock. Aside from the 6-speed manual trans, corvette gen 5 front brakes, 1LE drive shaft, 4th Gen disc brake fbody rear end.

2011 leaf SL, white, portable 240v CHAdeMO, trailer hitch, new batt as of 2014.

|

|

|

|

|

The Following User Says Thank You to oil pan 4 For This Useful Post:

|

|

Today Today

|

|

|

|

Other popular topics in this forum...

Other popular topics in this forum...

|

|

|

|

06-29-2015, 10:54 PM

06-29-2015, 10:54 PM

|

#32 (permalink)

|

|

Full sized hybrid.

Join Date: Apr 2015

Location: Colorado

Posts: 602

Suzy - '13 Toyota Avalon Hybrid XLE 90 day: 37.18 mpg (US)

Thanks: 369

Thanked 108 Times in 84 Posts

|

Quote:

Originally Posted by Daox

Do you have any pictures of this exhaust manifold for reference? I did a quick google image search, but I really don't know exactly what I'm looking for.

|

Here's a comparison with an OEM VW heat exchanger (right) and the best aftermarket heat exchanger available (left). Note the sort of fins the OEM has on the inside as well. Even with all those fins and two heat exchangers per car the VW Beetle wasn't prized for it's heat.

|

|

|

|

|

The Following User Says Thank You to Isaac Zackary For This Useful Post:

|

|

06-29-2015, 10:59 PM

06-29-2015, 10:59 PM

|

#33 (permalink)

|

|

Full sized hybrid.

Join Date: Apr 2015

Location: Colorado

Posts: 602

Suzy - '13 Toyota Avalon Hybrid XLE 90 day: 37.18 mpg (US)

Thanks: 369

Thanked 108 Times in 84 Posts

|

Quote:

Originally Posted by oil pan 4

The old carbureted engines used a heat shroud around the 1 or 2 of the exhaust manifold exhaust primaries to give the carb some warm air almost immediately after startup.

This was just mostly so it would idle and not stall constantly right after a good cold startup.

The exhaust manifolds get real hot but its not very easy to get a high volume of really hot air off them.

|

To add to your post, starting in the 1970's these became thermostatically controlled so that changing air temps did't affect the air density and therefore the air fuel ratio. The thermostatic temp was usually around 110° F. |

|

|

|

06-29-2015, 11:58 PM

06-29-2015, 11:58 PM

|

#34 (permalink)

|

|

Corporate imperialist

Join Date: Jul 2011

Location: NewMexico (USA)

Posts: 11,312

Thanks: 273

Thanked 3,584 Times in 2,845 Posts

|

I bought a thermostatic air intake valve from Russia a few months ago. Its set point was 35'C.

Another point about surface area inside heat exchangers.

In boiler design they use about 10 to 12 square feet of surface area per horsepower.

Air isn't nearly the working fluid that water is.

__________________

1984 chevy suburban, custom made 6.5L diesel turbocharged with a Garrett T76 and Holset HE351VE, 22:1 compression 13psi of intercooled boost.

1989 firebird mostly stock. Aside from the 6-speed manual trans, corvette gen 5 front brakes, 1LE drive shaft, 4th Gen disc brake fbody rear end.

2011 leaf SL, white, portable 240v CHAdeMO, trailer hitch, new batt as of 2014.

|

|

|

|

|

The Following User Says Thank You to oil pan 4 For This Useful Post:

|

|

06-30-2015, 08:40 AM

06-30-2015, 08:40 AM

|

#35 (permalink)

|

|

Administrator

Join Date: Dec 2007

Location: Germantown, WI

Posts: 11,203

Thanks: 2,501

Thanked 2,590 Times in 1,556 Posts

|

Very interesting and good info guys, thanks!

So, it really looks like the biggest difficulty is going to be getting the air warmed up enough, especially at the flow rates we are thinking about. The efficiency of the exhaust heat to air exchanger is going to be the thing that makes or breaks this. Perhaps it will have to extend down the exhaust pipe a ways. It sounds like we're sorely lacking in surface area.

Anyway, moving forward, I pulled the EGT gauge out of my Tercel this weekend. The next step will be making a mount to put it on the Metro manifold with some insulation around it. I'd like to see how fast the manifold gets up to temperature versus the coolant. Even if the air idea doesn't work out, this will be useful for coming up with other ideas, and knowing how soon we get usable heat.

|

|

|

|

06-30-2015, 10:27 AM

06-30-2015, 10:27 AM

|

#36 (permalink)

|

|

Thalmaturge

Join Date: Mar 2011

Location: The edge of nowhere

Posts: 1,167

Thanks: 769

Thanked 649 Times in 432 Posts

|

The first gen Insight did something like you're talking about (exhaust heat recovery) by the simple expedient of having the exhaust manifold cast into the head (and water jacketed).

I guess the way I'd go about it would be an electric coolant pump teed off one of the return with the output teed in on the intake side. Feed it to a length of copper piping wrapped around the exhaust manifold... seems like it would speed heating up a bit.

Pierburg Cooland Pumps CWA 50 $75 - DIY Electric Car Forums |

|

|

|

06-30-2015, 12:03 PM

06-30-2015, 12:03 PM

|

#37 (permalink)

|

|

Administrator

Join Date: Dec 2007

Location: Germantown, WI

Posts: 11,203

Thanks: 2,501

Thanked 2,590 Times in 1,556 Posts

|

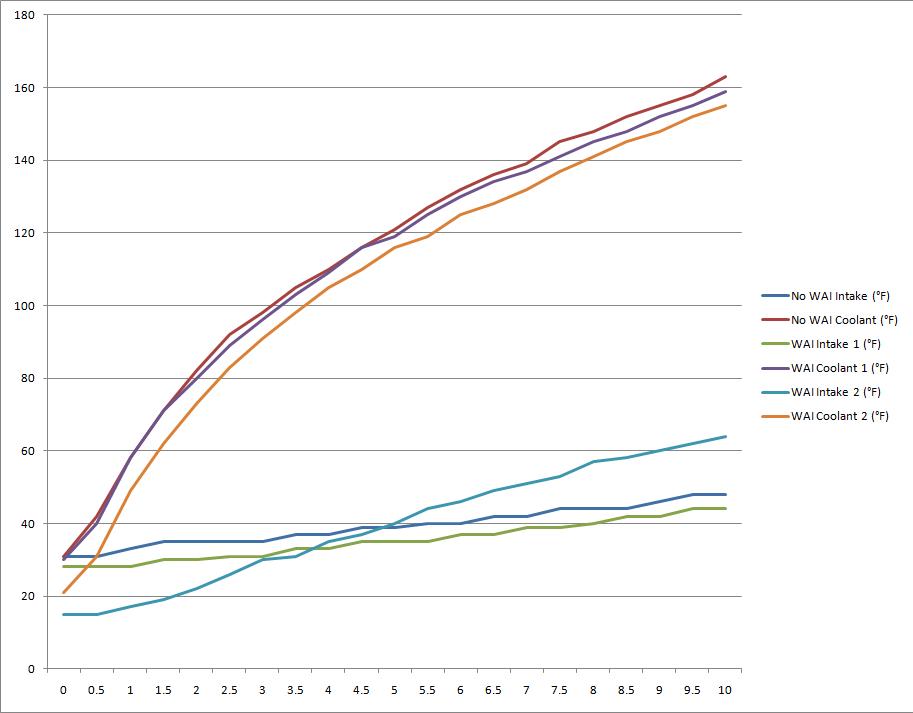

Just to further drive Oil Pan's and Isaac Zackary's points about not enough exhaust surface area home is actually my own testing from years ago haha. I was googling and found it here.  http://ecomodder.com/forum/showthrea...-up-11471.html

http://ecomodder.com/forum/showthrea...-up-11471.html

Its basically a test of a horrible WAI I made. After 10 minutes of idling (which is only around 16 CFM!), I saw intake air temps of 65°F (15F ambient).

|

|

|

|

06-30-2015, 05:01 PM

06-30-2015, 05:01 PM

|

#38 (permalink)

|

|

Permanent Lurker

Join Date: May 2011

Location: Czechoslovakia (sort of), Europe

Posts: 348

Dáčenka - '10 Dacia / Renault Logan MCV 1.5 dCi (X90 k9k) 90 day: 47.08 mpg (US)

Thanks: 129

Thanked 198 Times in 92 Posts

|

Quote:

Originally Posted by Daox

<snip>

The numbers aren't super amazing, but they are substantial I think. I think its reasonable to assume we can get 400°F temp air with 200 CFM giving us a possible 5600W, but at 50% heat exchanger efficiency we're looking at 2800W. If we compare this to MetroMPG's block heater vs time chart (test on his Metro), that would give us a 70F coolant temp rise in 12 minutes. Obviously, this also isn't realistic because everything has a warm up time. The manifold isn't going to instantly be making 400F air, and certainly not at 200 CFM.

|

Other side of the coin is what can you get from your exhaust?

From my back-of-the-envelope calculations the energy that leaves your Metro exhaust in the form of heat is about 6 kW, so I would not expect that you will get more than that.

(Why: 1 liter displacement, assuming 2000 rpm, that means internal airflow 1000 liters per minute, around 17 liters per second worth of heat in exhaust gases hot around 300 Kelvins.

lets assume it is air with thermal capacity about 1,2 Joule per liter per Kelvin, lets assume you can cool it down to ambient temp - whole 300 Kelvins to be optimistic. That gives me Q=F*cp*dT=6120 W. Correct me if i am wrong)

Just out of curiosity,

what is the exhaust tip temperature? The temperature difference between manifold and ?opening? (how do you call the very end of exhaust?) can tell the maximum amount of energy you can reasonably get from your heat exchanger, because that is the heat your exhaust system radiates to the

atmosphere now.

- i would propose something like hose-in-hose heat exchanger: enclose whole exhaust system with aluminum flashing leaving 1-2 cm gap around, optionally put insulation on the flashing, seal well. Cold air is sucked at the end of the car and goes to the engine compartment all the way, pre-heated by exhaust. Maybe try to use the flexible aluminum duct you used to make WAI? |

|

|

|

06-30-2015, 10:24 PM

06-30-2015, 10:24 PM

|

#39 (permalink)

|

|

Corporate imperialist

Join Date: Jul 2011

Location: NewMexico (USA)

Posts: 11,312

Thanks: 273

Thanked 3,584 Times in 2,845 Posts

|

If you need something more durable, but formable like aluminum foil get some stainless steel foil. Just be careful with it, when you cut it, it will try to cut you back.

__________________

1984 chevy suburban, custom made 6.5L diesel turbocharged with a Garrett T76 and Holset HE351VE, 22:1 compression 13psi of intercooled boost.

1989 firebird mostly stock. Aside from the 6-speed manual trans, corvette gen 5 front brakes, 1LE drive shaft, 4th Gen disc brake fbody rear end.

2011 leaf SL, white, portable 240v CHAdeMO, trailer hitch, new batt as of 2014.

|

|

|

|

07-01-2015, 09:47 AM

07-01-2015, 09:47 AM

|

#40 (permalink)

|

|

Administrator

Join Date: Dec 2007

Location: Germantown, WI

Posts: 11,203

Thanks: 2,501

Thanked 2,590 Times in 1,556 Posts

|

I have no idea what the exhaust tip temperature is. That is a good question though. However, there are so many variables that its impossible to just say it drops 300C and get a wattage number out of it. It all depends on engine load, rpm, airflow over the pipe etc.

I'll hopefully get to making a bracket for the EGT sensor soon. I'll video my gauges on my daily commute one or two times to compare warm up times of the coolant and exhaust manifold. From there, we can see if using the manifold (and probably exhaust piping) is even worth it, or if we should junk the hot air idea and go the route Toyota did and put the heat exchanger inside the exhaust pipe (which is definitely more effective, but also more complex).

|

|

|

|

|