01-21-2011, 02:28 PM

01-21-2011, 02:28 PM

|

#11 (permalink)

|

|

Master EcoModder

Join Date: Mar 2008

Location: USA

Posts: 568

Thanks: 1

Thanked 73 Times in 58 Posts

|

FWIW, I'm told that urethane foam may be better from a chemical compatibility standpoint, as Gorilla glue is just liquid urethane. Further, since polystyrene foams are dissolved by polyester resin, you need to use more expensive epoxy with them, another reason to stick with urthane foam in the first place. Not hotwire-able due to toxic outgassing, urethane foam is nonetheless said to be easier to sculpt and shape with sanding, grinding, etc..

For compound curves, consider kerfing the back side of the foam.

|

|

|

|

|

The Following User Says Thank You to Otto For This Useful Post:

|

|

Today Today

|

|

|

|

Other popular topics in this forum...

Other popular topics in this forum...

|

|

|

|

01-21-2011, 06:20 PM

01-21-2011, 06:20 PM

|

#12 (permalink)

|

|

Left Lane Ecodriver

Join Date: Aug 2008

Location: Buffalo, NY, USA

Posts: 2,257

Thanks: 79

Thanked 287 Times in 200 Posts

|

I have a feeling, 2011 is the Year of the Boattail.  |

|

|

|

01-21-2011, 07:02 PM

01-21-2011, 07:02 PM

|

#13 (permalink)

|

|

MPGuino Supporter

Join Date: Oct 2010

Location: Hungary

Posts: 1,808

iNXS - '10 Opel Zafira 111 Anniversary Suzi - '02 Suzuki Swift GL

Thanks: 831

Thanked 709 Times in 457 Posts

|

Yah, I think so, too. I might start work on version 2 this weekend. Tempted to use something more substantial for the frame than FoamulaR, though.

|

|

|

|

01-21-2011, 07:04 PM

01-21-2011, 07:04 PM

|

#14 (permalink)

|

|

MPGuino Supporter

Join Date: Oct 2010

Location: Hungary

Posts: 1,808

iNXS - '10 Opel Zafira 111 Anniversary Suzi - '02 Suzuki Swift GL

Thanks: 831

Thanked 709 Times in 457 Posts

|

Oh, and if you do decide to use resin for your fiberglass shell, be sure to completely cover the exposed polystyrene with a good masking tape. It's as what Otto said - Fiberglass resin will very quickly eat FoamulaR (or any other polystyrene).

|

|

|

|

01-21-2011, 07:12 PM

01-21-2011, 07:12 PM

|

#15 (permalink)

|

|

Left Lane Ecodriver

Join Date: Aug 2008

Location: Buffalo, NY, USA

Posts: 2,257

Thanks: 79

Thanked 287 Times in 200 Posts

|

Polyester resin will eat styrofoam, and knock you out. Wear a respirator. However, epoxy resin produces lighter composites, evolves much less toxic vapor, and is compatible with foam. At $65/gal, it's twice the price of polyester, but it's money well spent.

|

|

|

|

01-21-2011, 07:14 PM

01-21-2011, 07:14 PM

|

#16 (permalink)

|

|

MPGuino Supporter

Join Date: Oct 2010

Location: Hungary

Posts: 1,808

iNXS - '10 Opel Zafira 111 Anniversary Suzi - '02 Suzuki Swift GL

Thanks: 831

Thanked 709 Times in 457 Posts

|

Sorry for the confusion - I tend to call polyester resin "resin," and epoxy resin "epoxy."

|

|

|

|

01-21-2011, 07:42 PM

01-21-2011, 07:42 PM

|

#17 (permalink)

|

|

Recreation Engineer

Join Date: Dec 2009

Location: Somewhere USA

Posts: 525

Thanks: 333

Thanked 138 Times in 103 Posts

|

At most home improvement chains you can get foil coated foam board in full sheets. The foiled (not in the Snidley Whiplash sense though) side should be eco(nomically as in polyester) FG resin friendly. The foil layer also provides radiant shielding so your truck bed under such a foam-glassed cap wouldn't become a solar sauna.

BTW, I've found TAPPlastics.com a good place to buy resin and hardner. Anyone have other recommended sources? |

|

|

|

01-21-2011, 09:36 PM

01-21-2011, 09:36 PM

|

#18 (permalink)

|

|

T-100 Road Warrior

Join Date: Apr 2008

Location: The Woodlands, TX

Posts: 1,921

Thanks: 3,502

Thanked 1,395 Times in 968 Posts

|

|

|

|

|

01-22-2011, 10:10 AM

01-22-2011, 10:10 AM

|

#19 (permalink)

|

|

MPGuino Supporter

Join Date: Oct 2010

Location: Hungary

Posts: 1,808

iNXS - '10 Opel Zafira 111 Anniversary Suzi - '02 Suzuki Swift GL

Thanks: 831

Thanked 709 Times in 457 Posts

|

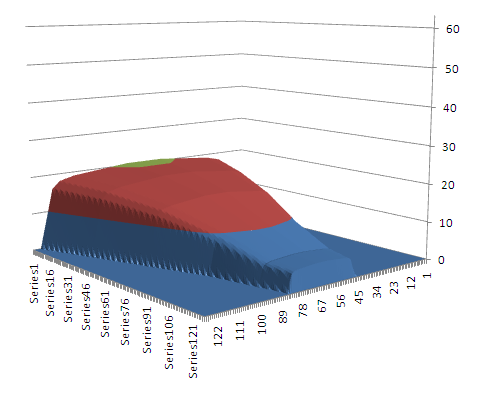

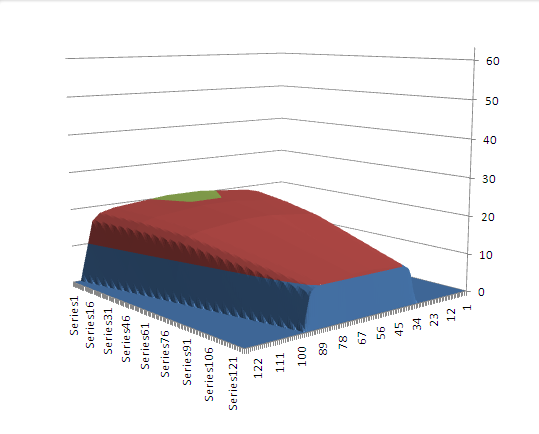

Here was the final MS Excel workup for the old aerocap

...and here's the workup for version 2

This will give an idea of what the completed version 2 aerocap will look like.

|

|

|

|

01-22-2011, 10:14 AM

01-22-2011, 10:14 AM

|

#20 (permalink)

|

|

T-100 Road Warrior

Join Date: Apr 2008

Location: The Woodlands, TX

Posts: 1,921

Thanks: 3,502

Thanked 1,395 Times in 968 Posts

|

Are you gonna put in a rear window? Is this one gonna be hinged/have a hatch so you have access to the bed?

|

|

|

|

|