11-15-2007, 10:56 PM

11-15-2007, 10:56 PM

|

#41 (permalink)

|

|

Batman Junior

Join Date: Nov 2007

Location: 1000 Islands, Ontario, Canada

Posts: 22,541

Thanks: 4,085

Thanked 6,989 Times in 3,619 Posts

|

03-15-2006, 03:32 Pm

i guess we're kind of committed now...

fortunately they delivered it in the middle of the afternoon, when most of the neighbours weren't home.

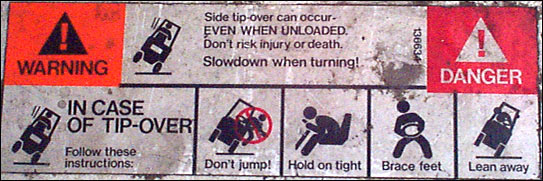

got gravity? good, because the forklift came without a battery ("batteries not included. some assembly required"). note the technician "driving" the forklift off the truck bed.

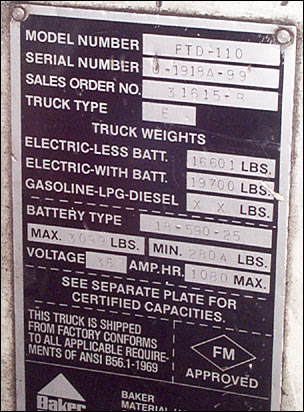

the vehicle on the left is nearly 10 times the weight of the vehicle on the right.

|

|

|

|

Today Today

|

|

|

|

Other popular topics in this forum...

Other popular topics in this forum...

|

|

|

|

11-15-2007, 10:57 PM

11-15-2007, 10:57 PM

|

#42 (permalink)

|

|

Batman Junior

Join Date: Nov 2007

Location: 1000 Islands, Ontario, Canada

Posts: 22,541

Thanks: 4,085

Thanked 6,989 Times in 3,619 Posts

|

delivery was $125. we haven't decided if we'll have to have the trucking co. come back for the chassis to take it to the recycler, or whether we'll tow it ourselves (a friend has a 4wd hemi ram). the recycler is about 3 km from the house (2 mi.) we'll get about $200 for the scrap metal.

|

|

|

|

11-15-2007, 10:57 PM

11-15-2007, 10:57 PM

|

#43 (permalink)

|

|

Batman Junior

Join Date: Nov 2007

Location: 1000 Islands, Ontario, Canada

Posts: 22,541

Thanks: 4,085

Thanked 6,989 Times in 3,619 Posts

|

03-15-2006, 06:16 Pm

Quote:

|

Originally Posted by someone

might be able to sell some of the extra knick knacks off that thing

|

knick knacks, yeah. there are 2 huge hydraulic pistons in the front. it's a dual stage boom that probably extends up about 15-18 feet. plus the pumps and the valves and the couplings. they might be worth something to someone hydraulically inclined. other than that, it's just a LOT of steel.

we hooked up 3 deep cycle batts in series using jumper cables and fired it up. turned it around and moved it closer to the edge of the driveway to make it easier to get a car in/out of the garage.

that might have been a mistake! you can see the bricks move under the wheels, sinking in, especially near the edge. but, at least a brick driveway can be fixed afterwards. this thing would ruin an asphalt driveway. |

|

|

|

11-15-2007, 10:59 PM

11-15-2007, 10:59 PM

|

#44 (permalink)

|

|

Batman Junior

Join Date: Nov 2007

Location: 1000 Islands, Ontario, Canada

Posts: 22,541

Thanks: 4,085

Thanked 6,989 Times in 3,619 Posts

|

03-15-2006, 10:51 Pm

Quote:

|

Originally Posted by someone

Hey keep the lift and use it to raise cars to work under them!! Easy way to do a belly pan!

|

you know, looking at that thing has me thinking similar thoughts. except more like: man, how flimsy our little cars are!

definitely easy to do a belly pan with this. i wish we could somehow use it to lift *itself* up so get at the motors. they have to come out from underneath. the technician says that's how they take them out at work - use another truck to lift up the back end and then block it. my buddy is tracking down some heavy duty jacks tomorrow. i'm going to start tracing wires to figure out how it's put together. |

|

|

|

11-15-2007, 11:00 PM

11-15-2007, 11:00 PM

|

#45 (permalink)

|

|

Batman Junior

Join Date: Nov 2007

Location: 1000 Islands, Ontario, Canada

Posts: 22,541

Thanks: 4,085

Thanked 6,989 Times in 3,619 Posts

|

03-17-2006, 08:45 Pm

latest news...

we can't use the lift to press down, unfortunately. it goes down by gravity only.

ramps... this thing wouldtn't really be able to drive up ramps with the juice we're (not) supplying it from our jumper-cabled 3 x 12v battery pack.

i'm seriously going to have a hard enough time driving the thing out of 1 - 2 inch divots its wheels have compressed into the driveway since i parked it on wednesday. truly. on the outside (softer) edge of the driveway, the narrower (steering) tire/wheel has pushed the bricks down about 2.5 inches. the larger & wider (front, lift end) wheels haven't sunk too much - maybe 1/2 inch.

spent today tracing wires, making crude schematics, and removing gew-gaws for possible ebay disposal: safety strobe, reverse beeper, horn, spotlights, hours-of-use meter...

also phoned up the company we got it from to ask if they had an extra service manual for the electronics side of things. i should have asked for this when we agreed to buy it. the tech said he figured they had an extra manual kicking around - hopefully they'll come through for us. that will save us mucho time in tracing, mapping & understanding all the components. a plea to the EVDL for any info on the antique EV-1 controller only netted one reply (unfortunately not too detailed - though he commended our "score" and said the EV-1 electronics are dead reliable, which is good news - and maybe self-evident considering their 25 year age and still-working condition  ).

we borrowed and picked up a 20 ton railway jack this afternoon (used for lifting the rails for repairing the rail bed, i think). it's a manual "ratchet" type jack, a lot like an old car "bumper" jack, except on serious, serious steroids, and with a 5-foot handle.

so this weekend we'll see about raising & blocking the back end of the beast and performing the various motor-ectomies, and possibly hydraulic pump-ectomies too. |

|

|

|

11-25-2007, 07:40 PM

11-25-2007, 07:40 PM

|

#46 (permalink)

|

|

Batman Junior

Join Date: Nov 2007

Location: 1000 Islands, Ontario, Canada

Posts: 22,541

Thanks: 4,085

Thanked 6,989 Times in 3,619 Posts

|

03-17-2006, 09:03 Pm

irony of the week: took delivery of the forklift on wednesday.

thursday: geo metro conversion offered on the EV discussion list (EVDL) - for FREE to whoever comes and picks it up (in connecticut). needs batteries and cosmetic work (had been vandalized - windows, dents).

|

|

|

|

11-25-2007, 07:42 PM

11-25-2007, 07:42 PM

|

#47 (permalink)

|

|

Batman Junior

Join Date: Nov 2007

Location: 1000 Islands, Ontario, Canada

Posts: 22,541

Thanks: 4,085

Thanked 6,989 Times in 3,619 Posts

|

03-18-2006, 08:40 Am

Quote:

|

Originally Posted by SVOboy

CT eh? You think it'll get picked up quickly?

|

ct is probably 10-12 hrs away from here.

but the free metro ev was claimed within an hour of that post going up.

we will stay the course! onwards to frankenswift! suzukistein! |

|

|

|

11-25-2007, 07:42 PM

11-25-2007, 07:42 PM

|

#48 (permalink)

|

|

Batman Junior

Join Date: Nov 2007

Location: 1000 Islands, Ontario, Canada

Posts: 22,541

Thanks: 4,085

Thanked 6,989 Times in 3,619 Posts

|

03-18-2006, 06:05 Pm

today: planned to jack up the forklift and begin the motorectomies. but we broke the (wooden) jack handle in short order. the jack, btw, must be at least 50 years old.

by the time we got a replacement "handle" (7 foot length of 2.5 inch pipe), we decided instead to just do a "test lift" instead.

it's surprising how long it can take 2 guys to figure out the basic operation of a dual action mechanical ratchet jack. anyway, we eventually did, and now the baker fork truck is resting on its frame on a couple of long wooden blocks, instead of slowly sinking further into the driveway at its tiny rear wheels.

also finished removing the gew-gaws, a number of steel panels, and the "headache bar" (roll cage). tomorrow we'll plan out our blocking strategy for the lift in a bit more detail. the motorectomies will likely happen sometime this week.

also, watched many hours of the 12 hrs of sebring in between playing with the forklift. that cool diesel audi is kicking gasoline's butt big time...

|

|

|

|

11-25-2007, 07:43 PM

11-25-2007, 07:43 PM

|

#49 (permalink)

|

|

Batman Junior

Join Date: Nov 2007

Location: 1000 Islands, Ontario, Canada

Posts: 22,541

Thanks: 4,085

Thanked 6,989 Times in 3,619 Posts

|

03-19-2006, 08:51 Pm

some more pitchers...

beauty and the beast, another angle

that sinking feeling - we have since jacked it up and blocked it under the frame, so there's no weight on the skinny rear wheels any more.

ok, now i feel better

made in cleveland, ohio (i cut the bottom off). note the weight, with and without batt.

this week's plan: move it part way into the garage to use the concrete floor to raise & block the rear. motorectomies, control panelectomy, and partial hydraulics-ectomy, then call the scrap yard to come get the carcass. |

|

|

|

11-25-2007, 07:44 PM

11-25-2007, 07:44 PM

|

#50 (permalink)

|

|

Batman Junior

Join Date: Nov 2007

Location: 1000 Islands, Ontario, Canada

Posts: 22,541

Thanks: 4,085

Thanked 6,989 Times in 3,619 Posts

|

03-21-2006, 07:42 Pm

today's update: we jumper-cabled the 36v string of marine batteries together again and moved the forklift most of the way into the garage this afternoon (wouldn't go in all the way because of the boom height), chocked the wheels and commenced "the forklift lift" - with a 15-ton railway jack. the "lift" was necessary because the motors can only come out from underneath, and we opted not to take the cutting torch route to make our own access panels.

once lifted and blocked at multiple points using a *lot* of wood, two motor-ectomies were performed: the power steering motor (permanent magnet .88 hp continuous duty) and one of the hydraulic pump motors (possibly also PM - only 2 terminals - but it didn't have any other specifications on it - a mystery motor for now.)

that hydraulic motor is a beast: 8 inch diameter, 110 lbs. with that weighty revelation, suddenly our main concern about the traction motor's ability to go in the swift isn't its size, but its heft. it's going to be a monster - i'm guessing 200-400 lbs.

how much does a small four-cylinder engine with accessories weigh? 200 lbs?

we might have to get a beefier host vehicle that can take it. something like... a forklift?

|

|

|

|

|