03-24-2017, 09:40 PM

03-24-2017, 09:40 PM

|

#51 (permalink)

|

|

It's all about Diesel

Join Date: Oct 2012

Location: Porto Alegre, Rio Grande do Sul, Brazil

Posts: 12,996

Thanks: 0

Thanked 1,711 Times in 1,527 Posts

|

Pretty much of what could be doable at a reasonable cost to improve the efficiency of a reciprocating engine had already been put into commercial production, while a handful of other configurations such as opposing-piston are slowly making a comeback, but most of the internal components are not going to have their basic designs changed to such a greater extent. OTOH there's still a lot of room for improvements at the engine-driven accessories in order to decrease the load they add to the engine.

|

|

|

|

Today Today

|

|

|

|

Other popular topics in this forum...

Other popular topics in this forum...

|

|

|

|

03-09-2025, 03:53 AM

03-09-2025, 03:53 AM

|

#52 (permalink)

|

|

Master EcoModder

Join Date: Aug 2022

Location: South Africa

Posts: 738

Thanks: 278

Thanked 298 Times in 259 Posts

|

Interesting, if a very impracticable idea.

It has me wondering what suspension bushing style 'rubber' mounting of the condrod might have on an engine..?

Just a 'Thought Experiment', assuming the ...'rubber' can handle the force of combustion etc:

Imagine that inner steel sleeve is the small end bearing and the outer steel sleeve is the condrod.

Assuming momentum overcomes 'piston to sleeve' friction; one should get a slightly longer stroke (swept volume) on all but the compression-power, 'stroke ends'.

A higher swept volume is good (for all the usual reasons) and there should be a perceptible increase in engine 'smoothness'..?

For the end of the compression and the beginning of the power stroke:

The rubber should compress some, despite the piston deceleration, thx to the compression pressure.

That means a lower compression ratio, for a higher swept volume.

Then when the pressure 'hits' the piston on the power stroke; the rubber will compress more and later give a bit of the OP's desired push to the crank at a more desirable crank angle..?

A similar 'rubber' thing could be done to the Big End side of the conrod too.

That increases the discussed effect and should reduce shock loads on the bearings.

All in all; a er... 'rubber mounted' conrod may just result in a perceptibly 'smoother', more refined 'feeling', slightly more efficient engine, with longer conrod bearing life and a less shock stressed/fatigued conrods..?

If I were doing my University Thesis on engines; this might be an experiment/subject worth considering!?

(What 'rubber' might withstand the pressures, temperatures and oil and how thick could one make it?)

Last edited by Logic; 03-09-2025 at 04:00 AM..

|

|

|

|

03-09-2025, 05:16 AM

03-09-2025, 05:16 AM

|

#53 (permalink)

|

|

Master EcoModder

Join Date: Aug 2012

Location: northwest of normal

Posts: 29,199

Thanks: 8,293

Thanked 9,050 Times in 7,480 Posts

|

Quote:

|

(What 'rubber' might withstand the pressures, temperatures and oil and how thick could one make it?)

|

Magnetic bearing?

__________________

.

.Without freedom of speech we wouldn't know who all the idiots are. -- anonymous poster

___________________

.

.You can't be wise and in love at the same time. -- Bob Dylan

|

|

|

|

03-09-2025, 10:04 PM

03-09-2025, 10:04 PM

|

#54 (permalink)

|

|

Master EcoModder

Join Date: Dec 2011

Location: New Zealand

Posts: 5,121

Thanks: 2,921

Thanked 2,589 Times in 1,608 Posts

|

The answer(s) nobody brought up in this thread are "offset crankshaft" and "combustion speed". An offset crankshaft imbalances an engine (not great for very high RPM operation) but greatly reduces stresses on both the cylinder liners, and on the conrods, and it also repositions TDC to a non zero crank angle.

Modern combustion chambers aim to speed up combustion above all else. The faster combustion completes, the less of it needs to happen before the piston reaches TDC, and the less negative work, and less conrod stress, there is.

|

|

|

|

|

The Following User Says Thank You to Ecky For This Useful Post:

|

|

03-10-2025, 01:33 AM

03-10-2025, 01:33 AM

|

#55 (permalink)

|

|

Master EcoModder

Join Date: Aug 2022

Location: South Africa

Posts: 738

Thanks: 278

Thanked 298 Times in 259 Posts

|

Quote:

Originally Posted by freebeard

Magnetic bearing?

|

Too heavy for any substantial force over the distance of the rubber thickness required I think..?

ie: One might magnetize gear teeth to repel each other as the distance between teeth where you'd want the repulsion to kick in is essentially zero.

But for a (rubber filled) gap of (thumb suck) 1 to 3 mm the magnets would be too heavy in this case?

You'd already be 'complicating' a std conrod.

Doing so as simply and lightly as possible would be key here. |

|

|

|

|

The Following User Says Thank You to Logic For This Useful Post:

|

|

Today, 01:36 AM

Today, 01:36 AM

|

#56 (permalink)

|

|

It's all about Diesel

Join Date: Oct 2012

Location: Porto Alegre, Rio Grande do Sul, Brazil

Posts: 12,996

Thanks: 0

Thanked 1,711 Times in 1,527 Posts

|

Quote:

Originally Posted by Logic

(What 'rubber' might withstand the pressures, temperatures and oil and how thick could one make it?)

|

I believe Mary Barra should be impeached for retreating GM from some regions, and for the usage of wet-belt timing in the engines of most Brazilian Chevrolets since late-2019, but if you would be willing to try some rubber, just look at the material used on those wet belts. And be careful with the oil you'll be using on the engine. |

|

|

|

|

The Following User Says Thank You to cRiPpLe_rOoStEr For This Useful Post:

|

|

Today, 02:07 AM

Today, 02:07 AM

|

#57 (permalink)

|

|

Master EcoModder

Join Date: Aug 2022

Location: South Africa

Posts: 738

Thanks: 278

Thanked 298 Times in 259 Posts

|

Quote:

Originally Posted by freebeard

Magnetic bearing?

|

Too heavy for any substantial force over the distance of the rubber thickness required I think..?

ie: One might magnetize gear teeth to repel each other as the distance between teeth where you'd want the repulsion to kick in is essentially zero AND you have oil.

But for a (rubber filled) gap of (thumb suck) 1 to 3 mm the magnets would be too heavy in this case?

You'd already be 'complicating' a std conrod.

Doing so as simply and lightly as possible would be key here.

As a mental exercise; I'm also not liking the directions in which the conrod would move when its say 1/3rd of the way down on the power stroke where the 'horizontal' force would push it 'in the wrong direction'.

ie: The offset Ecky is talking about would be 'in the wrong direction', but all 'in the conrod' so to speak.

Now we're talking oval holes/rubbers and where to stick the rubber and where not and the whole thing falls apart as far as 'simple' goes. |

|

|

|

Today, 02:47 AM

Today, 02:47 AM

|

#58 (permalink)

|

|

Master EcoModder

Join Date: Aug 2022

Location: South Africa

Posts: 738

Thanks: 278

Thanked 298 Times in 259 Posts

|

Quote:

Originally Posted by Ecky

The answer(s) nobody brought up in this thread are "offset crankshaft" and "combustion speed". An offset crankshaft imbalances an engine (not great for very high RPM operation) but greatly reduces stresses on both the cylinder liners, and on the conrods, and it also repositions TDC to a non zero crank angle.

|

Yes!  Offset is used and a lot has gone into keeping offset engines balanced.

While Obrist says/admits nothing of the sort, the Obrist Engine completely solves the vibration issue by having 2 counter rotating engines, joined by gears.

So any vibrational force has an exact, opposite, equal, canceling it out at any given time or point of rotation.

ie: A sum total of 'zero' vibration... (due to offset)

IF this has NOT in fact occurred to Obrist, it damn well should!

I think it's their little 'secret advantage' they're hoping 'no one will notice' or 'see'.

(I like the idea of a series PHEV Tesla btw. As the Bunny Hugger market is now saturated and regretting their choice; it's time IMHO. I hope Musk realizes that!)

Quote:

Originally Posted by Ecky

Modern combustion chambers aim to speed up combustion above all else. The faster combustion completes, the less of it needs to happen before the piston reaches TDC, and the less negative work, and less conrod stress, there is.

|

Yes, but I think you're missing the point here:

Lets say you have the head off an engine and have turned one of the pistons to exactly TDC.

Pushing down on the piston (by hand) has exactly zero effect on rotating the cankshaft as there is zero 'horizontal' component to the applied force.

The ONLY way you'll get the piston to move down is by loosening the main crankshaft bearings.

Now take the cylinder/s off too and turn the piston and conrod 90 degrees.

Now pushing on them applies a force that is at 90 degrees to the crankshaft where your push applies maximum torque to it.

Another way of looking at it:

With the cylinder/s on: Turn the crank till the same piston is 1/3rd to halfway down.

Now your push on the piston easily turns the crank.

That is the issue the OP was trying to ameliorate:

Ideally he/we wants TDC to be when the crank's at 90 degrees to the conrod...

Linear piston generator anyone!?

Last edited by Logic; Today at 03:02 AM..

|

|

|

|

|

The Following User Says Thank You to Logic For This Useful Post:

|

|

Today, 02:56 AM

Today, 02:56 AM

|

#59 (permalink)

|

|

Master EcoModder

Join Date: Aug 2022

Location: South Africa

Posts: 738

Thanks: 278

Thanked 298 Times in 259 Posts

|

Quote:

Originally Posted by cRiPpLe_rOoStEr

I believe Mary Barra should be impeached for retreating GM from some regions, and for the usage of wet-belt timing in the engines of most Brazilian Chevrolets since late-2019, but if you would be willing to try some rubber, just look at the material used on those wet belts. And be careful with the oil you'll be using on the engine.

|

Ye; those engines F-suck!

They cant be rebored either IIRC and have a one use plastic sump cover!

GM should now be avoided like the plague IMHO, but only ~1% of people know that, so...

But good point! I wonder what their wet belt is made of!? |

|

|

|

Today, 03:21 AM

Today, 03:21 AM

|

#60 (permalink)

|

|

Master EcoModder

Join Date: Dec 2011

Location: New Zealand

Posts: 5,121

Thanks: 2,921

Thanked 2,589 Times in 1,608 Posts

|

Almost all modern engines use offset crankshafts. The earliest one I'm aware of is the Insight engine, which may be why I know about it. Most Japanese engines moved to offset somewhere between 2008 and 2014 as part of a move to improve BSFC, because not only does it reduce stress, but it also reduces friction. It was basically the end of high RPM screamers, but extremely helpful in high compression turbo engines, which have exponentially more stress on the conrods, and more lateral force on the sidewalls. It redistributes forces, making the angles worse when the piston is moving upward (where it is essentially unloaded) and making them better at the point in reciprocation where forces are greatest. The greater the compression and cylinder pressure, the greater the "optimal" offset as far as stress is concerned, but relatively large offsets are almost always better for efficiency.

You can read what Yamaha wrote about it here:

https://global.yamaha-motor.com/desi...er_source/004/

Quote:

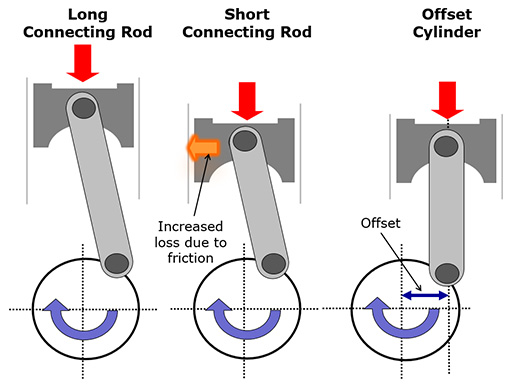

In general, the piston in an engine is pushed down by the explosive force of combustion in the combustion chamber and this is the origin of the drive force created by an engine. Strictly speaking, however, the piston is not actually pushed straight downward. Although it is small, there is in fact a diagonal component to the downward force that causes the piston to be pushed against the wall of the cylinder. This results in friction and a corresponding amount of horsepower loss. This friction-induced power loss can be reduced by lengthening the connecting rod, but lengthening the rod makes the engine heavier and larger overall.

The offset cylinder is a design that solves both of these inherently conflicting problems. This is accomplished by “offsetting” the cylinder from the crankshaft so that the axis of the piston and connecting rod are aligned vertically at the moment of combustion—when the pressure in the cylinder is at its peak. Doing this greatly reduces the friction from the diagonal force pushing the piston against the cylinder wall. At the same time, this enables more effective use of the energy produced by combustion. The engine in the F2.5A has a bore × stroke of 54 mm × 31.5 mm. The cylinder offset was set at a large 10 mm, increasing combustion efficiency and enabling a more compact design at the same time (#3).

In the offset cylinder design, the amount of offset affects the fuel efficiency, power output, engine response and more. Yamaha’s waza lies in determining the optimal amount of offset during development in line with the model’s characteristics.

Increasing the length of the connecting rod reduces the amount of friction between the piston and the cylinder wall, but it also makes the engine bigger (left). A shorter connecting rod produces more friction loss (center). The offset cylinder (right) enables both reduced loss and a more compact design.

|

|

|

|

|

|