01-15-2009, 08:13 AM

01-15-2009, 08:13 AM

|

#11 (permalink)

|

|

EcoModding Lurker

Join Date: Jul 2008

Location: Sweetwater, TN

Posts: 74

Thanks: 0

Thanked 2 Times in 2 Posts

|

Quote:

Originally Posted by NachtRitter

Interesting... that's actually what I thought the "h" in "h-bridge" stood for... hysterisis... Tells you what I know...  |

Actually shows what I know. Didn't know what an h bridge is. LOL

__________________

|

|

|

|

Today Today

|

|

|

|

Other popular topics in this forum...

Other popular topics in this forum...

|

|

|

|

01-15-2009, 09:04 AM

01-15-2009, 09:04 AM

|

#12 (permalink)

|

|

Administrator

Join Date: Dec 2007

Location: Germantown, WI

Posts: 11,203

Thanks: 2,501

Thanked 2,589 Times in 1,555 Posts

|

Quote:

Originally Posted by 93Cobra#2771

Interesting idea. You need to plumb your sensor not only after the tstat, but after the radiator as well. You want to know how hot the coolant is before it goes in the motor, not after the fact. This will give you a little safety factor. You also need to allow for overlap in the temps. In other words, door opens at 220 degrees and closes when at 210. Otherwise, hysterisis will take place and door will get "confused".

|

Ideally, you would either use the engines existing coolant temperature or an additional one very close to it just to measure the actual engine coolant temp. I chose to splice in the sensor after the thermostat as the best easy option from an installation and universal programming standpoint. All the controller needs to know is, is the engine coolant hot enough to open the grill? Yes/No. I don't see why you'd need a second sensor to answer that question. The hysterisis is programmed into the arduino code.

Quote:

Originally Posted by vtec-e

My guess is that you would end up having the fan coming on and off constantly. It would cool as normally, due to the grille being open, but things would heat up rapidly upon the grille closing. Having the motorised grille block open at a temp below the cut in temp of the fan would help level out the temps before the fan cuts in. What would be really "cool" would be to have it on a servo motor so the grille could close by an amount that would hold the temps at a pre-determined level. As you'd drive through cold pockets of air, it would close slightly and vice versa. Awesome!

ollie |

In addition to having the fan come on and off constantly, you don't want the coolant fan running. It draws a fair amount of electricity and we are doing this for efficiency's sake. I currently have my arduino code setup to open up the grill just before the fan comes on, and closes the grill just above max thermostat temp.

I agree, the servo controlled grill block would definitely be best. But, try finding cheap parts for it. Plus its more complex and this is already straining my electronics knowledge haha. If you know of any good solutions feel free to share!  |

|

|

|

01-15-2009, 09:09 AM

01-15-2009, 09:09 AM

|

#13 (permalink)

|

|

Administrator

Join Date: Dec 2007

Location: Germantown, WI

Posts: 11,203

Thanks: 2,501

Thanked 2,589 Times in 1,555 Posts

|

Quote:

Originally Posted by poindexter

Good point and cool idea.

I don't think just any grille block design would work with a door lock actuator. At some point I imagined having just a cover that hinges forward to open, but I think a door lock actuator wouldn't have any holding force once the voltage is removed. Maybe a grille block with a sliding slotted door would be good.

|

I think either one would work. If you wanted a hinged door you could just make an L shaped pivot arm and connect it to the actuator and door. My main concern is what design is superior when it comes to snow and ice. I tend to side with the hinged door for this reason since there is less surface area to have snow/ice build up on. Also, most h-bridges that I've seen have a 'brake' setting which would allow the actuator to hold in position. Not ideal as it still sucks electricity. However, I think most grill doors will be made of something fairly lightweight and it shouldn't be a problem holding them in place. But, this issue would suggest a sliding door would probably be better.

Quote:

Originally Posted by 93Cobra#2771

Actually shows what I know. Didn't know what an h bridge is. LOL

|

I never even knew h-bridges existed until about a week ago when dcb enlightened me to the fact that the arduino could not even come close to powering the actuator alone. Lucky for me, I never tried it.  |

|

|

|

01-15-2009, 09:39 AM

01-15-2009, 09:39 AM

|

#14 (permalink)

|

|

Master EcoModder

Join Date: Feb 2008

Location: belgium

Posts: 663

Thanks: 14

Thanked 61 Times in 44 Posts

|

that door lock actuator is just what i've been looking for... i've been messing with a motor an pulleys, but i can't get it reliable enough.

i think i'll stick with the fan trigger though. i've noticed about 90% of the time i can get away with a full block, but sometimes in summer if i happen to get stuck intraffic, things get to hot and the fan will come on, even without a block... the fan will stay on untill i get moveing again, so while the block will have the fan come on sooner i don't think it'll cause a lot of "flapping", especially since the fan already has a cutoff delay build in i'd imagine.

nothing but respect for people who will attempt something more sophisticated, but i don't think in practice it will add any benefit... i wouldn't like to build an overly complex system that doesn't do anything most of the time.

does anyone know what the wires on the door lock do? i think i'm going to get one that looks rather similar, what are the wires? is that ground and a 12v line for on/off or are their two temporary imputs of on/off?

__________________

aer·o·dy·nam·ics: the science of passing gass

*i can coast for miles and miles and miles*

|

|

|

|

01-15-2009, 10:00 AM

01-15-2009, 10:00 AM

|

#15 (permalink)

|

|

Administrator

Join Date: Dec 2007

Location: Germantown, WI

Posts: 11,203

Thanks: 2,501

Thanked 2,589 Times in 1,555 Posts

|

Quote:

Originally Posted by lunarhighway

does anyone know what the wires on the door lock do? i think i'm going to get one that looks rather similar, what are the wires? is that ground and a 12v line for on/off or are their two temporary imputs of on/off?

|

If you can get it to run off the fan temp switch that would definitely be a much cheaper way to go. However, I'm not sure how you'd go about doing that. The actuator does require a little bit of smarts to drive it properly. Check out post #4 in this thread to see how it works. |

|

|

|

01-15-2009, 10:41 AM

01-15-2009, 10:41 AM

|

#16 (permalink)

|

|

Administrator

Join Date: Dec 2007

Location: Germantown, WI

Posts: 11,203

Thanks: 2,501

Thanked 2,589 Times in 1,555 Posts

|

By the way, I sure could have used this thing today! It was a frigid -13F out this morning. I noticed as I got off the highway, with the heater on, my coolant temp just plummeted down into the 150s.

|

|

|

|

01-15-2009, 01:42 PM

01-15-2009, 01:42 PM

|

#17 (permalink)

|

|

EcoModder

Join Date: Jul 2008

Location: North Central Alabama

Posts: 572

Thanks: 110

Thanked 123 Times in 71 Posts

|

You may be able to do the Fan On / Fan Off method by hooking up two actuators, one that opens it when the fan comes on, one that closes it when the fan turns off... Not sure how to get it to work, but if it costs a few extra dollars up front to save a lot of headache, I would say it's worth it.

__________________

|

|

|

|

01-15-2009, 03:21 PM

01-15-2009, 03:21 PM

|

#18 (permalink)

|

|

EcoModding Lurker

Join Date: Jul 2008

Location: Sweetwater, TN

Posts: 74

Thanks: 0

Thanked 2 Times in 2 Posts

|

Quote:

Originally Posted by Daox

Ideally, you would either use the engines existing coolant temperature or an additional one very close to it just to measure the actual engine coolant temp. I chose to splice in the sensor after the thermostat as the best easy option from an installation and universal programming standpoint. All the controller needs to know is, is the engine coolant hot enough to open the grill? Yes/No. I don't see why you'd need a second sensor to answer that question. The hysterisis is programmed into the arduino code.

|

That's why I suggested putting the temp sensor after the radiator, or at least right before the exit of the lower hose. You want some type of feedback for the coolant coming out of the rad - it keeps you from finding out after the fact that the engine is getting too hot.

That is the way that most aftermarket electric fan assemblies use - temp at the rad. Ideal placement of the probe is within 4-6 inches vertically and 1-2 inches horizontally of the radiator outlet.

Putting it after the rad is perfect, as it gives you right then temps on whether or not there is sufficient airflow through the rad. Not after it makes a trip through the motor and heats up even more. I think this would make for more accurate control.

There was a great write up on stuff like this from an engineer, but alas the website is gone. That same engineer markets and sells aftermarket fan controllers that work with pulse modulation/infinitely variable speeds (I have one on my mustang).

Granted, you could pull the temp information from anywhere and figure in the difference, but there will still be some time delay involved.

My two cents worth. :-) Hopefully it makes decent sense, as I typed rather quickly and didn't review it before posting.

__________________

|

|

|

|

01-15-2009, 06:02 PM

01-15-2009, 06:02 PM

|

#19 (permalink)

|

|

Master EcoModder

Join Date: Feb 2008

Location: belgium

Posts: 663

Thanks: 14

Thanked 61 Times in 44 Posts

|

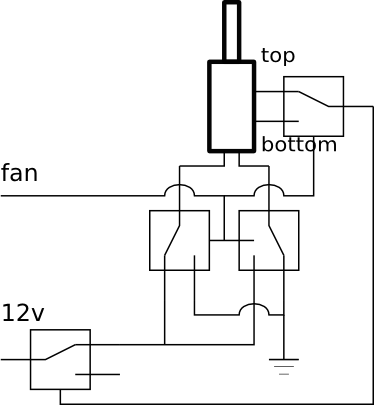

this is how i'd do it

the idea is:

fan switches relays... two which switch the position of the ground and the power line to the actuator. changeing its direction (fan on=extend, off = in) and one wich determines wich controle switch (fan on = monitor pistion full out, fan off = monitor piston full in) is monitored

this controle switch operates a 4th relay that switches the main power off if the pistion is at the end of its travel.

maybe not the most refined system but the logic could be used for something more advanced.

__________________

aer·o·dy·nam·ics: the science of passing gass

*i can coast for miles and miles and miles*

|

|

|

|

01-16-2009, 09:27 AM

01-16-2009, 09:27 AM

|

#20 (permalink)

|

|

Administrator

Join Date: Dec 2007

Location: Germantown, WI

Posts: 11,203

Thanks: 2,501

Thanked 2,589 Times in 1,555 Posts

|

Interesting setup lunarhighway. Let us know how it works out!

I ordered a few arduino's yesterday (I have a few projects in mind).

I'm still waiting on some input on my h-bridge selection! I'd really appreciate it.

|

|

|

|

|