06-10-2014, 07:07 PM

06-10-2014, 07:07 PM

|

#1 (permalink)

|

|

EcoModding Lurker

Join Date: Dec 2011

Location: Austin,Texas

Posts: 14

A.J. - '04 Honda Civic LX 90 day: 41.47 mpg (US) bruce - '08 Kawasaki Ninja 650 R 90 day: 46.52 mpg (US) Big Blue - '09 Ford F-150 LX 90 day: 17.33 mpg (US) dr - '13 Kawasaki DR650 90 day: 55.32 mpg (US)

Thanks: 2

Thanked 64 Times in 9 Posts

|

Boat Tail Construction-Civic Sedan

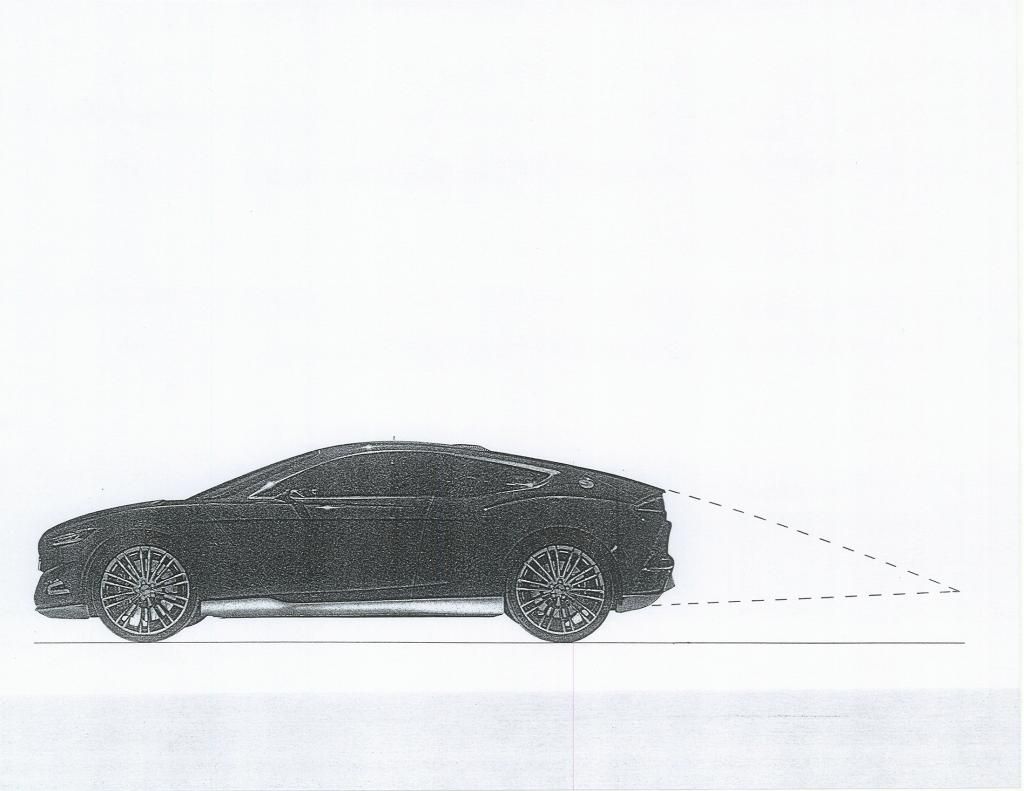

After viewing the 'redneck boat tail' I have decided to make a boat tail. I have overlayed the template on images and they seem alright. Can anyone tell me if they are wrong in an way? I was not sure if the side taper was done correctly.

For materials,

I will probably build the frame as a tubular structure. I was thinking Metal conduit or PVC piping? For anyone with PVC experience, do you think it would be strong enough to support the weight? This seems easier since I can use a heat gun and bend it to the right shape.

I want to build the frame and then cover it in foam. After sanding/filing the foam, I want to fiberglass it with probably two layers of 4 oz cloth. Does this sound reasonable?

For the rear section, I will probably use 10mm coroplast that I have lying around.

Please give suggestions and point out problems if you can

|

|

|

|

Today Today

|

|

|

|

Other popular topics in this forum...

Other popular topics in this forum...

|

|

|

|

06-10-2014, 07:27 PM

06-10-2014, 07:27 PM

|

#2 (permalink)

|

|

Master EcoModder

Join Date: Jan 2008

Location: Sanger,Texas,U.S.A.

Posts: 16,420

Thanks: 24,474

Thanked 7,410 Times in 4,800 Posts

|

plan-view contour

Here is the Cd 0.12,1959 MG EX 181 streamliner and its contour.

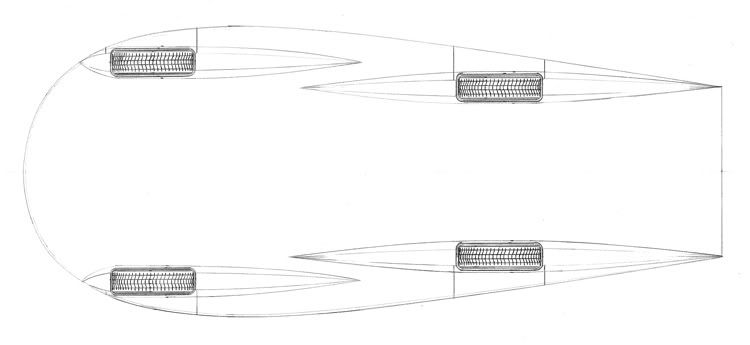

Here's 'Template' plan-view I'm recommending

__________________

Photobucket album: http://s1271.photobucket.com/albums/jj622/aerohead2/

|

|

|

|

|

The Following User Says Thank You to aerohead For This Useful Post:

|

|

06-10-2014, 08:05 PM

06-10-2014, 08:05 PM

|

#3 (permalink)

|

|

Master EcoModder

Join Date: Jun 2009

Location: SC Lowcountry

Posts: 1,796

Thanks: 226

Thanked 1,353 Times in 711 Posts

|

Quote:

For materials,

I will probably build the frame as a tubular structure. I was thinking Metal conduit or PVC piping? For anyone with PVC experience, do you think it would be strong enough to support the weight? This seems easier since I can use a heat gun and bend it to the right shape.

I want to build the frame and then cover it in foam. After sanding/filing the foam, I want to fiberglass it with probably two layers of 4 oz cloth. Does this sound reasonable?

For the rear section, I will probably use 10mm coroplast that I have lying around.

Please give suggestions and point out problems if you can

|

I think PVC is to flimsy. It is also heavy and would be hard to attach. A 10' stick of 1/2" EMT weighs around 2.2 lbs. is rigid and can be bent easily, but will have to be welded.

A big plus for using 1/2" builders foam is that one side has aluminum foil and the other side a plastic film. The aluminum foil side will keep the fiberglass resin from making contact with the foam and melting it.

> |

|

|

|

06-10-2014, 08:17 PM

06-10-2014, 08:17 PM

|

#4 (permalink)

|

|

Drive less save more

Join Date: Jul 2011

Location: Vancouver Island, Canada

Posts: 1,189

Thanks: 134

Thanked 162 Times in 135 Posts

|

Man, a 10' length of EMT sure is light , I guess being a 1/2" it is very light.

Sweet

__________________

Save gas

Ride a Mtn bike for errands exercise entertainment and outright fun

__________________

|

|

|

|

06-10-2014, 09:58 PM

06-10-2014, 09:58 PM

|

#5 (permalink)

|

|

EcoModding Lurker

Join Date: Dec 2011

Location: Austin,Texas

Posts: 14

A.J. - '04 Honda Civic LX 90 day: 41.47 mpg (US) bruce - '08 Kawasaki Ninja 650 R 90 day: 46.52 mpg (US) Big Blue - '09 Ford F-150 LX 90 day: 17.33 mpg (US) dr - '13 Kawasaki DR650 90 day: 55.32 mpg (US)

Thanks: 2

Thanked 64 Times in 9 Posts

|

I unfortunately don't have immediate access to a welder. Do you think I could braze/solder it or would there not be enough adhesion?

|

|

|

|

06-10-2014, 11:20 PM

06-10-2014, 11:20 PM

|

#6 (permalink)

|

|

Master EcoModder

Join Date: Jun 2009

Location: SC Lowcountry

Posts: 1,796

Thanks: 226

Thanked 1,353 Times in 711 Posts

|

.

It should be mig welded. Mig is easy to learn and can be used for many different welding projects. There are 115v flux core mig welders for $200 or less that will do the job.

Or, find a friend who has one and get him to help for beer and burgers.

> |

|

|

|

06-11-2014, 04:37 AM

06-11-2014, 04:37 AM

|

#7 (permalink)

|

|

Not Doug

Join Date: Jun 2012

Location: Show Low, AZ

Posts: 12,256

Thanks: 7,268

Thanked 2,236 Times in 1,726 Posts

|

Could you not just build it out of foam and then fiberglass it?

http://ecomodder.com/forum/showthrea...ect-13533.html |

|

|

|

|

The Following User Says Thank You to Xist For This Useful Post:

|

|

06-11-2014, 02:07 PM

06-11-2014, 02:07 PM

|

#8 (permalink)

|

|

EcoModding Lurker

Join Date: Dec 2011

Location: Austin,Texas

Posts: 14

A.J. - '04 Honda Civic LX 90 day: 41.47 mpg (US) bruce - '08 Kawasaki Ninja 650 R 90 day: 46.52 mpg (US) Big Blue - '09 Ford F-150 LX 90 day: 17.33 mpg (US) dr - '13 Kawasaki DR650 90 day: 55.32 mpg (US)

Thanks: 2

Thanked 64 Times in 9 Posts

|

For the side taper:

I have overlaid both my original template and the suggested template on the car. Will the original not work because it is too aggressive of an angle for the air to stay attached? The suggested template seems pretty flat or maybe I did not line it up correctly. Obviously I would rather have a flatter angle with no air separation versus a steeper one but I also want the cross section to be as small as possible at the end.

|

|

|

|

06-11-2014, 04:01 PM

06-11-2014, 04:01 PM

|

#9 (permalink)

|

|

Master EcoModder

Join Date: Jan 2008

Location: Sanger,Texas,U.S.A.

Posts: 16,420

Thanks: 24,474

Thanked 7,410 Times in 4,800 Posts

|

too aggressive?

Quote:

Originally Posted by bs25942

For the side taper:

I have overlaid both my original template and the suggested template on the car. Will the original not work because it is too aggressive of an angle for the air to stay attached? The suggested template seems pretty flat or maybe I did not line it up correctly. Obviously I would rather have a flatter angle with no air separation versus a steeper one but I also want the cross section to be as small as possible at the end.

|

If your car was actually a half-body,the sides would be identical to the top.With this,the flow velocity and pressure along the sides would be closer to the top flow.

With the CIVIC,the airflow over the greenhouse is faster,and at a lower pressure than at the sides do to the way the streamlines are divided at the nose and windshield.

With less body camber,and higher pressure,the side flow cannot support attached flow over as radical a curvature as on top without triggering separation.

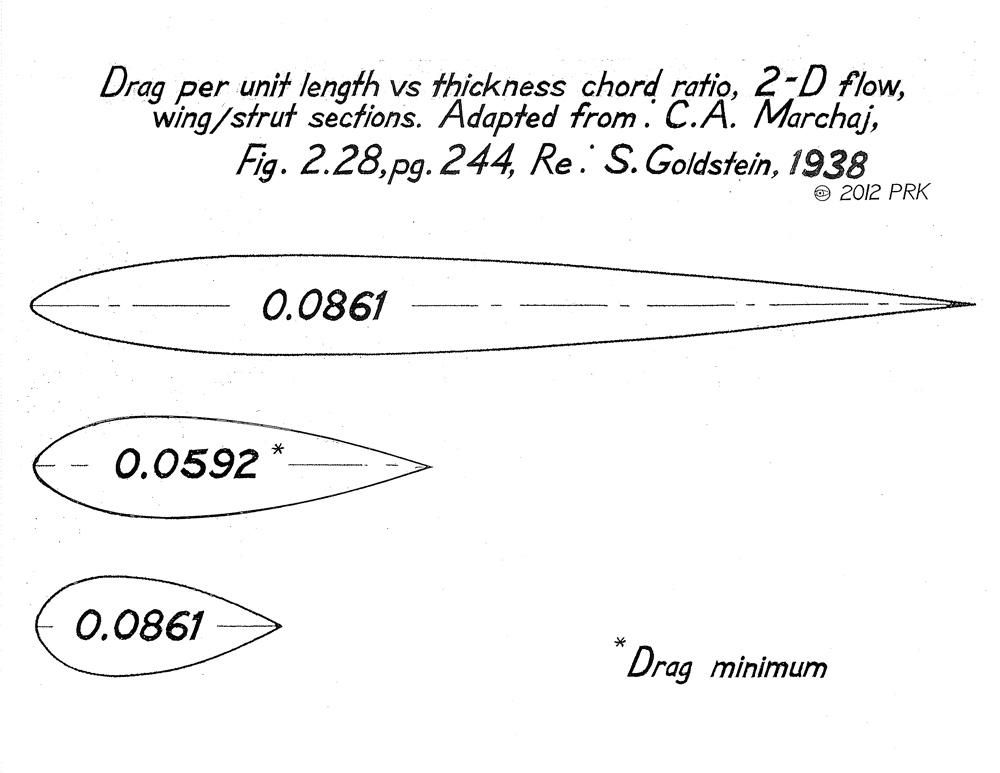

The more gentle curvature of the 2-D strut of minimum drag (second image,center table) has the sectional density necessary for a more gradual pressure rise which will not jeopardize the boundary layer.

A number of the lowest drag cars ever constructed happen to use this more gentle 2-D section profile for their plan view boat-tailing.

Until more data comes along I believe it to be the safest bet.

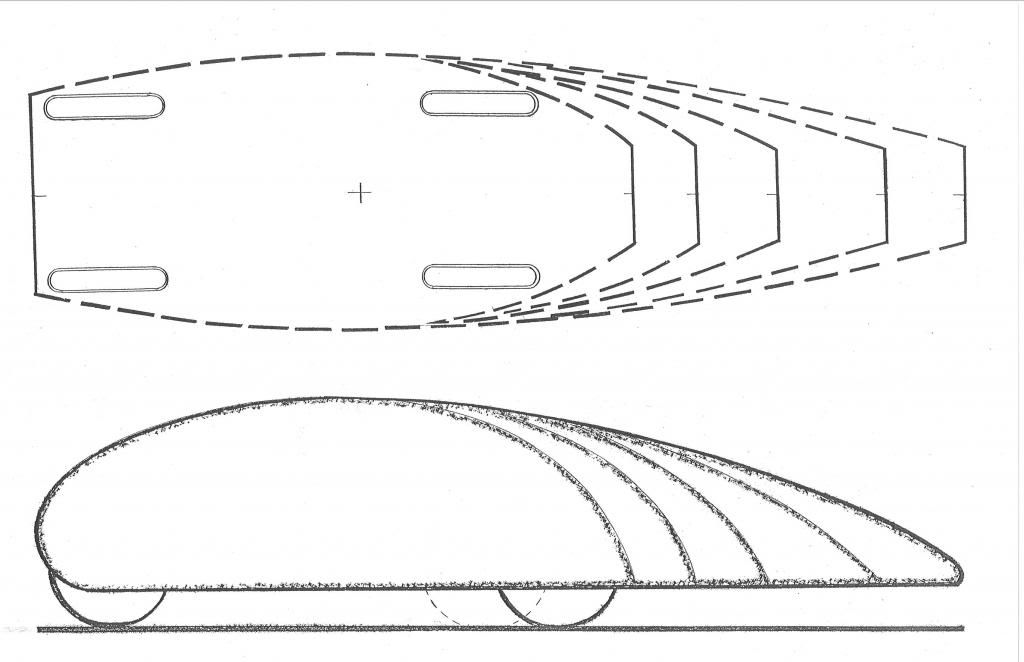

Here is Kamm's research model for Jaray-type rear ends.The longest, most gentle plan-view contour netted him the lowest drag.

__________________

Photobucket album: http://s1271.photobucket.com/albums/jj622/aerohead2/

|

|

|

|

|

The Following User Says Thank You to aerohead For This Useful Post:

|

|

06-11-2014, 06:43 PM

06-11-2014, 06:43 PM

|

#10 (permalink)

|

|

Too busy for gas stations

Join Date: May 2013

Location: The intersection of TN/MS/AL

Posts: 460

Turtle - '92 Honda Civic Vx Team Honda 90 day: 67.09 mpg (US) Rolla - '10 Toyota Corolla Le Beast - '91 Chevy V2500 Bus - '01 VW Eurovan MV Speed - '93 Harley bored and storked Harley w/ turbo/ nitrous 90 day: 53.09 mpg (US) Cal - '68 Ford Mustang GT/CS

Thanks: 87

Thanked 176 Times in 114 Posts

|

Quote:

Originally Posted by bs25942

I unfortunately don't have immediate access to a welder. Do you think I could braze/solder it or would there not be enough adhesion?

|

Most schedule 10 pvc will bend with time and heat cycling. Schedule 40+ may work, but is very sensitive to uv.

For the emt:

Straight sections: Sleeve, epoxy and rivet

Joints, flatten, then epoxy and rivet. Works best if pipe continues to on (think a continuous square, flattened at corners).

Removable sections rivnut instead of epoxy and rivet.

__________________

Shooting for 600 miles of range at 65-70 mph out of a vx.

|

|

|

|

|