I've got three weddings to go to in as many weeks coming up, and well over 5000 miles for them.

So, I decided it was time for some semi-aero changes.

First was a truck bed cover. I have a pretty standard low profile over-rail toolbox in the bed, and I'm not willing to give it up unless I could get a really killer deal on a in-bed toolbox (I'm cheap normally, but really on a budget for this project). Basically it would have to be a straight trade, or free.

So I started looking for a cover that would fit with the toolbox. The only ones I found didn't work with the low profile toolbox (handle & lock on the toolbox are below level of bed rails), wouldn't raise in the front (I'm not removing the cover just to get in the toolbox), or just too danged expensive ($600 and up).

I pondered this for several weeks, daydreaming and looking at pictures of other bed covers for ideas. I really wanted a cover like Big Dave has for his truck, but I couldn't figure out how to make it open up for access to the toolbox in a fairly simple manner. I'm a mechanical engineer by training, so I can come up with all kinds of theoretical things that 'should' work. But, I have to build this myself, and I put myself on a really tight budget for it.

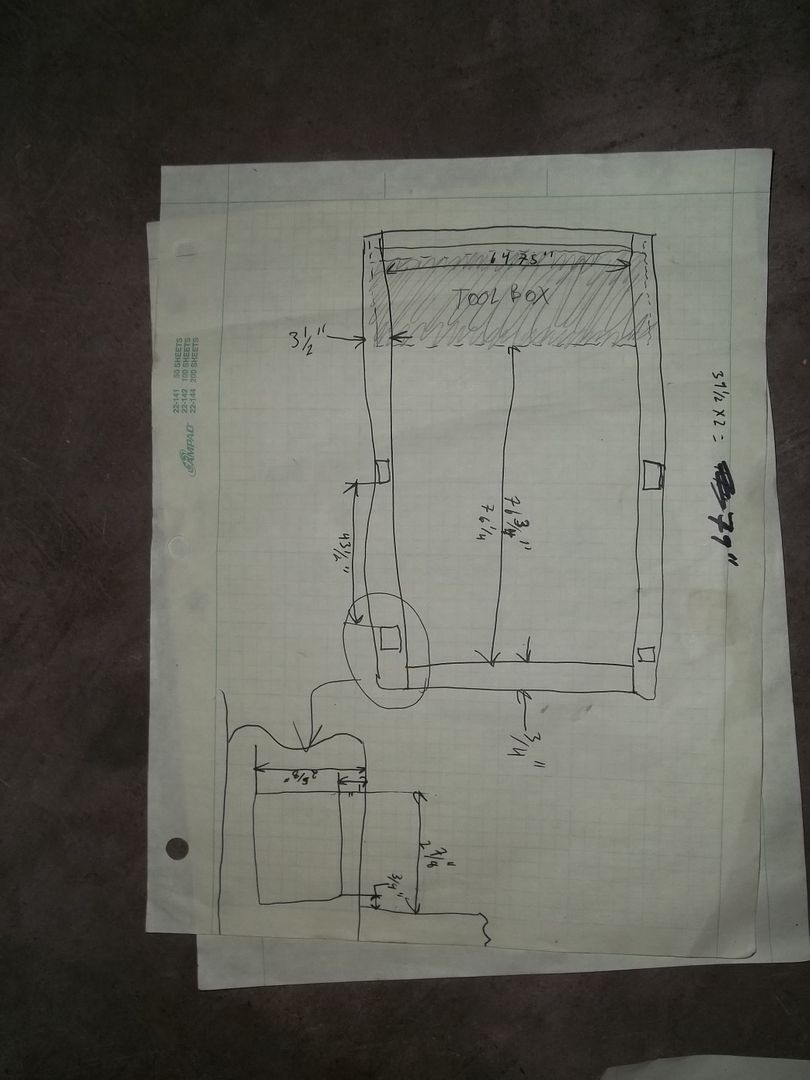

Then I started sketching out my ideas. And promptly threw them out one by one for various reasons that made them impractical to build, or just plain wouldn't work.

Eventually I settled on this design. The results are what you see here. It still isn't done, I need to make a little latch of some sort to keep it from bouncing around and rattling.

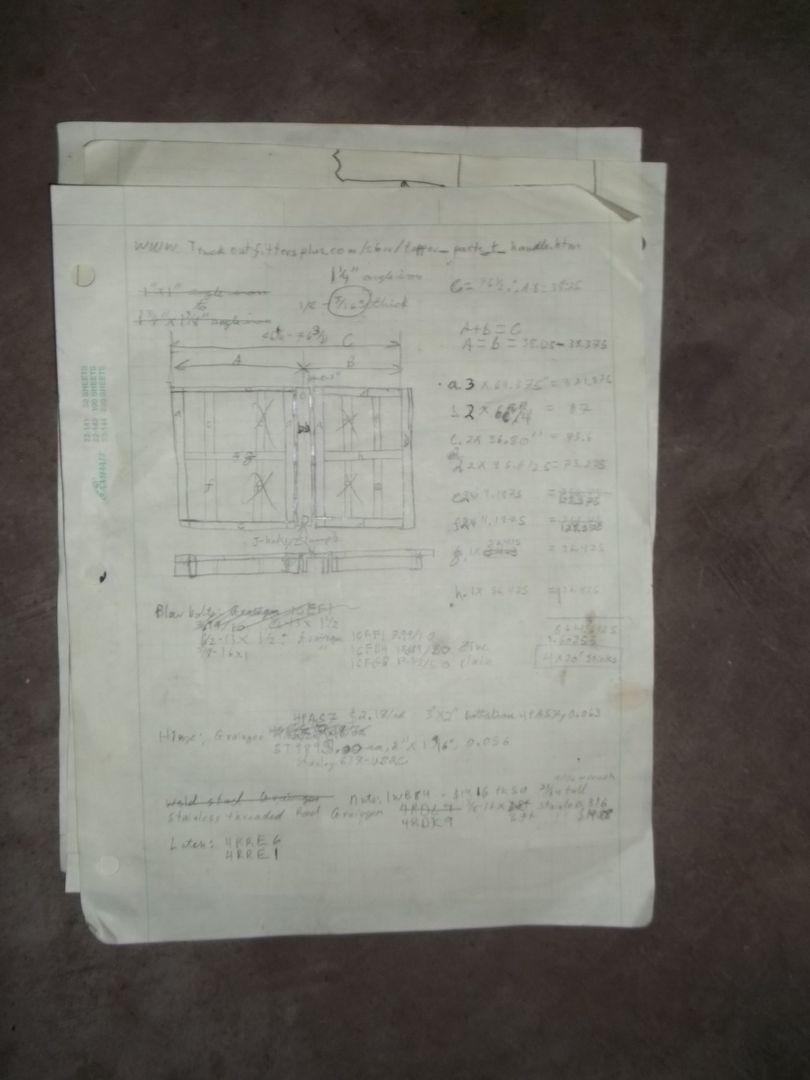

BOM:

Vendor Part number Desc pkg qty qty unit price

Metal world N/A Angle 1 1/4" x 1 1/4" x 3/16" x 20' cut in half 1 3 36.70

Lee's truevalue hdw N/A 5/16 X 3" stainless carriage bolt 1 7 2.00

Menards 554705 spray on bed liner 1 3 7.49

Menards N/A 5/16 x 2 SS carriage bolt 23 1 6.99

Menards N/A 5/16" SS nuts 96 1 5.99

Menards N/A 5/16" SS washers 87 1 4.99

Menards N/A 2 1/2" hinge captive pin 1 4 2.49

And, pictures:

One other thing worth mentioning is that I built the front panel pretty much 'to print' (such as the 'print' is). Then built the center frame and 'clamps'. After that I built the rear frame and actually tack welded it on the truck to make sure it was exactly the right size.

In all but a few spots where the inner edge of the bed rail is bent, the angle iron clears the sides of the rails by probably 1/8"-3/16" on each side. Tailgate clearance is about the same.

Total: $183.40, approx 12-18 hours labor, 4 gallons of sweet iced tea, 8 gallons of water, and a few gatorades.

Weight I estimate at about 80-100lbs. It can be lifted with one hand, it's just awkward.

I used a draper head canvas for this project. Any of the side draper canvas from a CaseIH 2142, 2152, 2162 or MacDon D50, D60, or FD70 will work. It doesn't matter what size the head is. The shortest canvas is over 130 inches long.

You have to cut off the fiberglass rods and the V-guides, but that's pretty easy with a utility knife.

I put it on upside-down. So the side that the crop normally rides on is facing the inside of the bed.

So, if you have a dealership nearby that sells or services draper heads, see if they have any that have been removed.

You could probably use material from other brands, but I have no idea what size those are, so no clue if it would work as well.

It's not pretty, but it should work. And I am rather surprised how much water it does keep out. We had a torrential storm the week after I built this and there was a small pool at the front near the toolbox, and a few droplets scattered around the rest of the bed, but otherwise it was surprisingly dry.