11-09-2014, 10:33 PM

11-09-2014, 10:33 PM

|

#11 (permalink)

|

|

Batman Junior

Join Date: Nov 2007

Location: 1000 Islands, Ontario, Canada

Posts: 22,534

Thanks: 4,082

Thanked 6,979 Times in 3,614 Posts

|

Nice work.

What's next on the list?

|

|

|

|

Today Today

|

|

|

|

Other popular topics in this forum...

Other popular topics in this forum...

|

|

|

|

11-09-2014, 11:57 PM

11-09-2014, 11:57 PM

|

#12 (permalink)

|

|

EcoModding Apprentice

Join Date: Apr 2012

Location: Charlotte, NC

Posts: 134

Thanks: 146

Thanked 110 Times in 47 Posts

|

Well, that you ask...

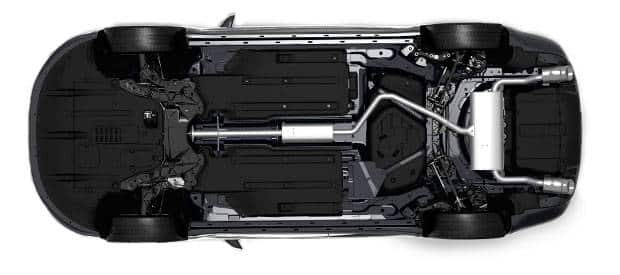

Just aft of the front tires, there is a spot that isn't covered by underfloor panel, it's about 24" long, 12" or so wide. This is righthand side of the car, image right is just behind the front tire, at left you can see where the factory underfloor panel picks up:

So I made this to fill it:

It fits as so:

And:

I've made one for the right and one for the left. I've only installed the right hand side. When you design and work in a vacuum there are sometimes unintended consequences that are pretty obvious when you step back. So it was only after installing the right hand side that I realized the reason the Dodge didn't extend that underfloor panel all the way forward as this is the spot where any car lift will pick up...doh. So I have two choices: remove entirely or modify taking that new fact into account. Naturally I can't leave it on as it will be crushed the first time I go for an oil change (or whatever). All a bit of a shame because while all this only cost about $10 total, it took a number of days on my lunch break to shape and then laminate the panels (fiberglass in this case). Oh well! I had a sinking feeling when I was contemplating the area as it's all done with a lot of deliberation, just couldn't figure out what their design intent was. Now I know...

Last edited by woodstock74; 11-10-2014 at 12:02 AM..

|

|

|

|

|

The Following 4 Users Say Thank You to woodstock74 For This Useful Post:

|

|

11-10-2014, 04:35 AM

11-10-2014, 04:35 AM

|

#13 (permalink)

|

|

EcoModding Lurker

Join Date: Nov 2014

Location: Pasadena CA

Posts: 8

Thanks: 1

Thanked 10 Times in 2 Posts

|

Nice work on the under panels !

|

|

|

|

11-10-2014, 10:19 AM

11-10-2014, 10:19 AM

|

#14 (permalink)

|

|

Batman Junior

Join Date: Nov 2007

Location: 1000 Islands, Ontario, Canada

Posts: 22,534

Thanks: 4,082

Thanked 6,979 Times in 3,614 Posts

|

Quote:

Originally Posted by woodstock74

Naturally I can't leave it on as it will be crushed the first time I go for an oil change (or whatever).

|

Well, it's not unprecedented: a few cars have full under-engine panels that require removal to do work like oil changes.

But of course the mechanics don't crush the panels before raising the car.

What will you do? Redesign, or removal before service? |

|

|

|

11-10-2014, 10:39 AM

11-10-2014, 10:39 AM

|

#15 (permalink)

|

|

EcoModding Apprentice

Join Date: Apr 2012

Location: Charlotte, NC

Posts: 134

Thanks: 146

Thanked 110 Times in 47 Posts

|

Quote:

Originally Posted by MetroMPG

Well, it's not unprecedented: a few cars have full under-engine panels that require removal to do work like oil changes.

But of course the mechanics don't crush the panels before raising the car.

What will you do? Redesign, or removal before service?

|

It'll be a pain to remove each time as they're pop riveted on and the plastic they're riveted in to is not the best (the few rivets I've had to remove tend to melt the plastic, creating an very undesirable large hole, when they inevitably heat up when being drilled out). So redesign, but it means a pretty drastic redesign as I'll have to dish out a large area for the foot for the car lift to go. The question then becomes, will the modified panel even do anything and am I wasting my time even further? I'm 50/50 on this; time spent vs. potential gain. So there's a strong possibility these come off permanently and end up on the wall of shame. Unless I can come up with a solution...anyone know of a removable fastener, not unlike the removable body fasteners that are on any modern car, that are good for thin material sections? Also reliable in that they snap into place with confidence? That might be the answer. If I can easily pop these off each time then voila, job done.

And now that I think about it, I have some fasteners that I was using on my Nissan Versa, before I killed that car, still left over...and I have the day off today...time to lay on my back in the driveway contemplating this I think! |

|

|

|

|

The Following User Says Thank You to woodstock74 For This Useful Post:

|

|

11-10-2014, 10:41 AM

11-10-2014, 10:41 AM

|

#16 (permalink)

|

|

EcoModding Apprentice

Join Date: Apr 2012

Location: Charlotte, NC

Posts: 134

Thanks: 146

Thanked 110 Times in 47 Posts

|

Quote:

Originally Posted by spray2020

Nice work on the under panels !

|

Thanks! |

|

|

|

11-10-2014, 10:55 AM

11-10-2014, 10:55 AM

|

#17 (permalink)

|

|

EcoModding Apprentice

Join Date: Apr 2012

Location: Charlotte, NC

Posts: 134

Thanks: 146

Thanked 110 Times in 47 Posts

|

Furthermore, the techniques I'm using here are very simple.

I take this foam insulation:

Shop GreenGuard Extruded Polystyrene Foam Board Insulation (Common: .56-in x 4-ft x 8-ft; Actual: 0.56-in x 4-ft x 8-ft) at Lowes.com

It's wicked cheap (and you get a lot for the price) and you can cut it (knife, bandsaw, file, whatever), sand it, etc. I laminate a number of pieces together with Super 77 spray glue (give yourself about 24 hours to let that set up; you can certainly do it sooner though, read the instructions on the Super 77) to get a desired piece to work on depending on what I'm doing. Only thing to note is that both sides of this sheet have a very thin plastic backing ply that picks and peels off very easily; remove it as it causes issues when you start sanding on a laminated stack up (the plastic starts to poke through).

After I've shaped the piece, I then simply lay up a composite material (fiber glass or carbon fiber) with epoxy resin over the foam. This is key, it HAS to be epoxy resin as polyester resin will attack the foam and you'll quickly end up with a gooey mess. Yes, epoxy resin is the hard thing to acquire inasmuch as you can walk into any Lowes and buy polyester, but can't for epoxy. Got a West Marine near by? They should have it.

Once laid up and cured I then tend to remove the foam with acetone as it's easier to place and locate a hollow panel than one that is solid (which you then would have to clearance over all the bits and bobs). Deflash the part, trim for clearance (I use these for trimming all composites as they chuck into any dremel and do the job for just about any thickness composite: Diamond Coated Rotary Cutting Discs 5 Pc), and mount. |

|

|

|

|

The Following 4 Users Say Thank You to woodstock74 For This Useful Post:

|

|

11-10-2014, 03:16 PM

11-10-2014, 03:16 PM

|

#18 (permalink)

|

|

EcoModding Apprentice

Join Date: Apr 2012

Location: Charlotte, NC

Posts: 134

Thanks: 146

Thanked 110 Times in 47 Posts

|

Ok, it'll work with the removable push type clips. The thickness stack up doesn't seem an issue at all and I've drilled out the rivets on the leading edge and everything seems stable/secure. These are the push type clips I'm using:

However, a second issue is this: I can't get the car up enough to drill the new holes (about 8 mm dia, .31") in the trailing edge of my panel. I have an angle attachment for my dremel, but it will only chuck 1/8" max. And I need to chuck .31" to drill the new holes for the push type clips. I have maybe 9" to play with; at the moment I have no means to jack the car up (the dremel angle attachment was the workaround for that in the past). Any ideas? I can look in to detaching the panel my underfloor infill panel ultimately attaches to and thus can pull everything off and drill off-car. Just not sure I can reach all the detachment points for the main panel. Guess I'll have to have another look at the situation. |

|

|

|

|

The Following User Says Thank You to woodstock74 For This Useful Post:

|

|

11-10-2014, 05:18 PM

11-10-2014, 05:18 PM

|

#19 (permalink)

|

|

Master EcoModder

Join Date: Aug 2011

Location: Warren, MI

Posts: 2,456

Thanks: 782

Thanked 669 Times in 411 Posts

|

Seems like your time might be better spent on a grille block, wheel skirts and boat tail. If you're set on messing around under the car, why not make an flat, smooth EV1 style ABS full belly pan?

__________________

He gave me a dollar. A blood-soaked dollar.

I cannot get the spot out but it's okay; It still works in the store

|

|

|

|

11-10-2014, 06:39 PM

11-10-2014, 06:39 PM

|

#20 (permalink)

|

|

EcoModding Apprentice

Join Date: Apr 2012

Location: Charlotte, NC

Posts: 134

Thanks: 146

Thanked 110 Times in 47 Posts

|

Car already has a underfloor, about 70% is covered. I'm just going for the rest where I can:

Have active grill shutters too; pointless to do anything else there. Wouldn't think of attaching a boat tail to a year old car either that's still under warranty. Wheel skirts are a possibility though, long term I think.

Quote:

Originally Posted by Sven7

Seems like your time might be better spent on a grille block, wheel skirts and boat tail. If you're set on messing around under the car, why not make an flat, smooth EV1 style ABS full belly pan?

|

|

|

|

|

|

The Following 2 Users Say Thank You to woodstock74 For This Useful Post:

|

|

|