11-25-2007, 08:34 PM

11-25-2007, 08:34 PM

|

#91 (permalink)

|

|

Batman Junior

Join Date: Nov 2007

Location: 1000 Islands, Ontario, Canada

Posts: 22,541

Thanks: 4,085

Thanked 6,989 Times in 3,619 Posts

|

05-07-2006, 04:29 Pm

got a welding lesson from my older brother today. torch brazing. very, very cool.

it's not too hard. i should rephrase that: it's probably hard to do "well" by the standards of a pro welder, but it's not too hard to get 2 pieces of metal to join together without ruining either of them (distorting / melting through).

the lessons were on pieces of sheet metal cut from the flanks of the red swift. (these cars are really melding together in true forkenswift style)

i was practicing on flat & clean pieces of suzuki clamped perfectly together, which is much different from contorting myself inside & underneath the blue car where the actual work needs to be done. that will be more of a challenge.

still... i'm really looking forward to trying this.

i borrowed a torch, and if i didn't have some work to get ready for tomorrow, i'd be out in the garage right now reciting the only thing i remember from shop class about using an oxy/acetylene setup:

"A" before "O", or up you go!

that will be my mantra this week.

|

|

|

|

Today Today

|

|

|

|

Other popular topics in this forum...

Other popular topics in this forum...

|

|

|

|

11-25-2007, 08:34 PM

11-25-2007, 08:34 PM

|

#92 (permalink)

|

|

Batman Junior

Join Date: Nov 2007

Location: 1000 Islands, Ontario, Canada

Posts: 22,541

Thanks: 4,085

Thanked 6,989 Times in 3,619 Posts

|

05-08-2006, 07:22 Pm

i did some actual torch welding tonight - and i only set the car on fire about 5 times!

nothing too serious: the factory undercoating/rubberized stuff on the bottom (outside) of the car was burning merrily away a couple of times. i was working inside the car, so i'm glad my brother spotted the first, um, flare-up (flare down?).

i could blow out the flames pretty easily, and got into a rhythm: tack a piece of metal inside the car... lean underneath and blow out the fire... tack another section inside the car... lean underneath and blow out the fire...

i already had the garden hose on standby beside the car before any of this happened, but it never came close to needing it. oh, and the fuel lines are on the OTHER side of the car, so that wasn't an issue (yet).

nevertheless, i'm going to continue doing this in the *driveway*, not in the garage.

as expected, brazing is much harder to do "in real life" than on the flat, clean, test pieces of metal we were practicing on yesterday. still fun though.

even more fun: i used a cutting wheel to hack a large chunk of the rear quarter panel off the red car which i'm using to make my repair pieces for the blue car. i guess i like wrecking stuff AND fixing stuff!

|

|

|

|

11-25-2007, 08:35 PM

11-25-2007, 08:35 PM

|

#93 (permalink)

|

|

Batman Junior

Join Date: Nov 2007

Location: 1000 Islands, Ontario, Canada

Posts: 22,541

Thanks: 4,085

Thanked 6,989 Times in 3,619 Posts

|

05-09-2006, 08:28 Pm

tried heating the undercoating stuff first, but it doesn't make it any easier to remove. heating it goes from gummy to exothermic, with no real in between phase that makes it easy to remove. so... i had a few more fires this evening.

on the positive side, i don't get fumes (from the fires), since the fires are underneath the car, and i'm working inside (and today, a nice light breeze kept the fresh air coming).

i brazed on a few more patches. i'm maybe half finished the welding now. it's getting a little easier too, though i certainly suck by pro standards.

i read a small college welding course manual last night that helped me to refine things a little. i didn't make any holes, and had better luck doing a continuous braze as opposed to a bunch of spot welds.

|

|

|

|

11-25-2007, 08:36 PM

11-25-2007, 08:36 PM

|

#94 (permalink)

|

|

Batman Junior

Join Date: Nov 2007

Location: 1000 Islands, Ontario, Canada

Posts: 22,541

Thanks: 4,085

Thanked 6,989 Times in 3,619 Posts

|

05-10-2006, 08:50 Pm

patched up some more holes tonight. more fires! more fun.

i'll be done the worst side (passenger) tomorrow, i think. the driver's side will take another couple of hours. Now I know why they invented electric welders (speed). a final hour to re-undercoat and re-paint stuff and bob's your uncle.

let this be a lesson to all of you living in the rust belt: rustproof your cars!

that's a lot of work on a $150 car (and dropping! thanks, ebay & teamswift.net).

|

|

|

|

11-25-2007, 08:36 PM

11-25-2007, 08:36 PM

|

#95 (permalink)

|

|

Batman Junior

Join Date: Nov 2007

Location: 1000 Islands, Ontario, Canada

Posts: 22,541

Thanks: 4,085

Thanked 6,989 Times in 3,619 Posts

|

05-10-2006, 09:02 Pm

on another note, a fellow EV enthusiast generously offered to donate a 36/48V curtis controller, an ammeter shunt, and contactors to the project.

he was given the parts in a custom made electric go kart that needed fixing up, but decided he's already got enough on his plate with his current conversion.

he has already donated the kart's 8 hp motor to the guy who built the $800 yugo EV (and who unfortunately had motor trouble not too long after).

the Curtis may be a good alternative to the 25 year-old controller that came with the forklift. also, it's a better controller for using one of the smaller pump motors if the drive motor turns out to be too big for the forkenswift's engine bay. |

|

|

|

11-25-2007, 08:38 PM

11-25-2007, 08:38 PM

|

#96 (permalink)

|

|

Batman Junior

Join Date: Nov 2007

Location: 1000 Islands, Ontario, Canada

Posts: 22,541

Thanks: 4,085

Thanked 6,989 Times in 3,619 Posts

|

05-11-2006, 08:50 Am

Someone asked...

Quote:

|

Are you using coat hangers for filler rod?

|

i've been using flux-coated brass rods. i've heard you can use coat hanger wire, but i haven't tried it. i'll give it a shot today and let you know what happens. |

|

|

|

11-25-2007, 08:39 PM

11-25-2007, 08:39 PM

|

#97 (permalink)

|

|

Batman Junior

Join Date: Nov 2007

Location: 1000 Islands, Ontario, Canada

Posts: 22,541

Thanks: 4,085

Thanked 6,989 Times in 3,619 Posts

|

05-11-2006, 11:30 Am

yup, coat hanger works, but its melting point is higher, so it's a bit harder to work (more of a chance i'll melt the car). also you'd need to add flux. but if you ever run out of brazing rods...

and the rods i'm using are bronze - i said brass by mistake.

|

|

|

|

11-25-2007, 08:39 PM

11-25-2007, 08:39 PM

|

#98 (permalink)

|

|

Batman Junior

Join Date: Nov 2007

Location: 1000 Islands, Ontario, Canada

Posts: 22,541

Thanks: 4,085

Thanked 6,989 Times in 3,619 Posts

|

05-11-2006, 06:16 Pm

passenger side done! (the worst side)

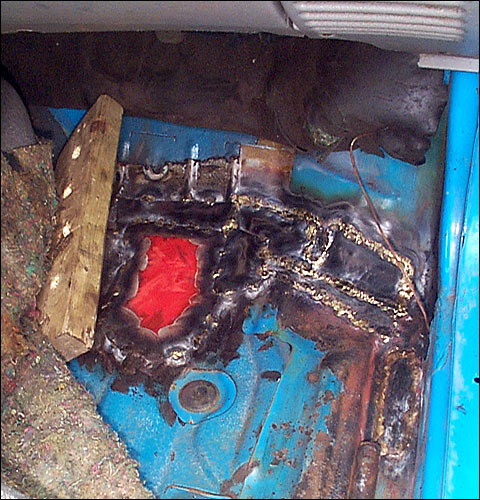

before...

after... (the red bit is paint i didn't burn/grind off the sheet metal from the red car. i hacked another chunk from it today. also, most of what you can see is just the final layer tacked on to make the floor flat again. there's more work underneath that's fully brazed and more ... structural.)

after after... (fresh rubberized undercoating to catch fire next time the floor needs welding)

|

|

|

|

11-25-2007, 08:40 PM

11-25-2007, 08:40 PM

|

#99 (permalink)

|

|

Batman Junior

Join Date: Nov 2007

Location: 1000 Islands, Ontario, Canada

Posts: 22,541

Thanks: 4,085

Thanked 6,989 Times in 3,619 Posts

|

RH77 says "great DIY"...

Quote:

|

Originally Posted by RH77

Wow, great DIY-ing. I guess if you haven't welded much before, you just have to try it, right? This is a great thread, BTW! Keep us posted...

|

And SVOboy adds..

Quote:

Indeed, this gives me hope for my own welding experimentation. I might buy another CRX with my friend that needs hella work just to get practice in with fixing rust and painting and ****.

Mehbe we'll make it an EV while we're at it,

|

|

|

|

|

11-25-2007, 08:42 PM

11-25-2007, 08:42 PM

|

#100 (permalink)

|

|

Batman Junior

Join Date: Nov 2007

Location: 1000 Islands, Ontario, Canada

Posts: 22,541

Thanks: 4,085

Thanked 6,989 Times in 3,619 Posts

|

05-12-2006, 10:53 Am

Somone speculated that the drain holes in the unibody need to be kept clear...

you know, i think it was the 2 open drains at the bottom of the firewall (they're actually in the underbody, just after the transition from firewall to underbody) that caused the rust i've been fixing.

the outboard drain is perfectly positioned to receive tire spray directly into it, and once the water (salty water in the winter) is inside, it's not going to dry up quickly. the inside floor, firewall, and underbody of the car form a roughly triangular shaped cavity accessed by those drain holes.

|

|

|

|

|