11-25-2007, 09:52 PM

11-25-2007, 09:52 PM

|

#111 (permalink)

|

|

Batman Junior

Join Date: Nov 2007

Location: 1000 Islands, Ontario, Canada

Posts: 22,534

Thanks: 4,082

Thanked 6,979 Times in 3,614 Posts

|

05-25-2006, 09:28 Pm

Update o' the day:

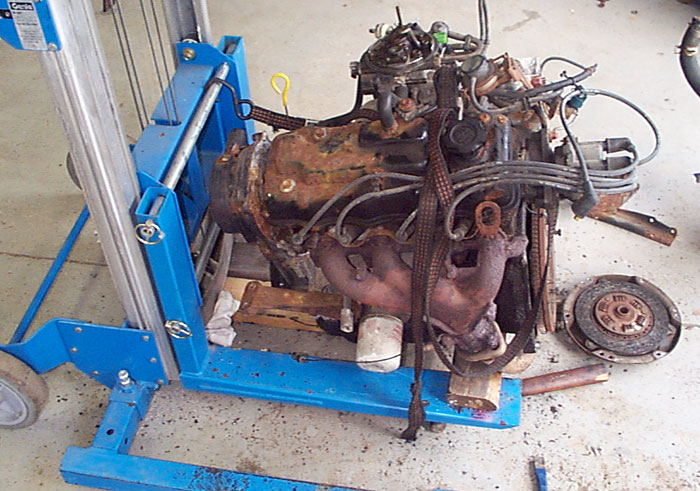

Spent another hour today working with ForkenSwift co-conspirator Ivan, getting the red car ready for its drive-trainectomy.

Axles removed. Piece of cake! I was fearing a stuck axle, as I once experienced when trying to change an alternator in my '89 Accord - yes, that's right: axle removal required for that job. (What were those engineers smoking...)

Doing this work raised a niggling doubt in my mind again about the ability to fit the big Baker drive motor into this car. I've been concerned about its length previously, but its, um, girth may be just as big a problem.

I hadn't looked at the drive shaft area before, and there doesn't seem to be much distance between the centerline of the input shaft and the axle. We're going to need a minimum of 6 inches separation there (motor is about 12 in. dia.), and my eyeball tape measure is set to "pessimistic". Hopefully the EBTM is also unreliable. (I do have a bad habit of jumping to negative conclusions when faced with mechanical uncertainty.)

But - no turning back now.

Also, separated/cut all other connections to the drive train, and loosened the mounting bolts, so the unit is mere minutes from independence when we get back at it on the weekend.

Pics of the dessicated Swift coming in a day or so. I do love disassembling/wrecking things.

|

|

|

|

Today Today

|

|

|

|

Other popular topics in this forum...

Other popular topics in this forum...

|

|

|

|

11-25-2007, 09:52 PM

11-25-2007, 09:52 PM

|

#112 (permalink)

|

|

Batman Junior

Join Date: Nov 2007

Location: 1000 Islands, Ontario, Canada

Posts: 22,534

Thanks: 4,082

Thanked 6,979 Times in 3,614 Posts

|

05-26-2006, 12:49 Pm

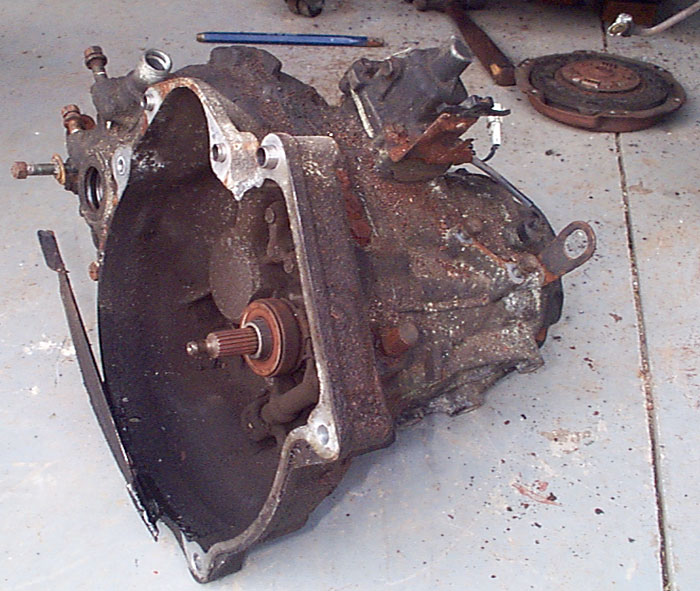

Drivetrain is out of the red car! Dropped it out the bottom. Easy easy. (Only forgot to disconnect a couple of ground straps... and the throttle cable - oops.)

Unfortunately, my EBTM was correct: once we got the transaxle off the motor and measured things, we confirmed we don't have the clearance for a direct shaft-to-shaft coupling of the 12 in. drive motor to the tranny's input shaft.

The problem is the drive motor's diameter is big enough that we don't have enough clearance for the half-shaft axle that goes from the diff, alongside the "back" of the motor, to the wheel.

Options... - We could try to offset the drive motor shaft from the transaxle input shaft and connect the two with gears, a short chain, or cogged belt.

...

- Could we omit an axle and modify the differential for one-wheel drive? (Likely revealing my ignorance of how diff's work here.)

...

- We *could* use one of the forklift's smaller (8 inch dia.) hydraulic pump motors, but they have internally splined shafts, which will require replacement/modification to be useful.

We would prefer to use the main drive motor if possible, since it's matched to the controller, having a field weakening circuit. Also it was serviced a few years ago.

Comments, suggestions? |

|

|

|

11-25-2007, 09:59 PM

11-25-2007, 09:59 PM

|

#113 (permalink)

|

|

Batman Junior

Join Date: Nov 2007

Location: 1000 Islands, Ontario, Canada

Posts: 22,534

Thanks: 4,082

Thanked 6,979 Times in 3,614 Posts

|

05-26-2006, 01:06 Pm

DAX suggests welding the differential to create a "spool" and going 1-wheel drive with the big motor.

---

Thanks DaX.

So it is possible. Interesting. I can't picture how a "spool" would be set up, since I don't really know how a diff works in the first place, but I'm sure I can figure it out. (Until I pulled the pressure plate off the motor this morning, I never had a clear understanding of clutch operation either. I had it all backwards, thinking the clutch plate was attached to the pedal...)

And regarding loss of traction, does that apply if you don't have a LSD? If I put a wheel on ice and one on pavement, the car won't go anywhere - the ice wheel just spins. So, no change there.

One thing I was wondering about was if it would affect handling - ie. would the steering "pull" all the time? Just when accelerating? Would it behave oddly in tight turns? (In one direction, the motor would run faster than the opposite turn.)

|

|

|

|

11-25-2007, 09:59 PM

11-25-2007, 09:59 PM

|

#114 (permalink)

|

|

Batman Junior

Join Date: Nov 2007

Location: 1000 Islands, Ontario, Canada

Posts: 22,534

Thanks: 4,082

Thanked 6,979 Times in 3,614 Posts

|

05-26-2006, 01:31 Pm

The "spool" idea becomes clear when you see a diff in motion. There's a good flash animation on this page:

http://auto.howstuffworks.com/differential3.htm

Weld the 2 red pinion gears together to form a "spool" and you've got a locked diff that would function in one-wheel drive mode.

1WD handling questions remain though. |

|

|

|

11-25-2007, 10:00 PM

11-25-2007, 10:00 PM

|

#115 (permalink)

|

|

Batman Junior

Join Date: Nov 2007

Location: 1000 Islands, Ontario, Canada

Posts: 22,534

Thanks: 4,082

Thanked 6,979 Times in 3,614 Posts

|

05-26-2006, 01:46 Pm

Offsetting: one concern that comes to mind is that it puts some lateral load (what's the proper term for that, engineering folks?) on both shafts. I wonder if that might have a negative effect on shaft bearings & seals.

|

|

|

|

11-25-2007, 10:00 PM

11-25-2007, 10:00 PM

|

#116 (permalink)

|

|

Batman Junior

Join Date: Nov 2007

Location: 1000 Islands, Ontario, Canada

Posts: 22,534

Thanks: 4,082

Thanked 6,979 Times in 3,614 Posts

|

DAX says, in part:

Quote:

|

Are you talking about a thrust load (parallel to the turning shafts) or a radial load (perpendicular to the turning shafts)?

|

|

|

|

|

11-25-2007, 10:01 PM

11-25-2007, 10:01 PM

|

#117 (permalink)

|

|

Batman Junior

Join Date: Nov 2007

Location: 1000 Islands, Ontario, Canada

Posts: 22,534

Thanks: 4,082

Thanked 6,979 Times in 3,614 Posts

|

05-26-2006, 04:07 Pm

I think doing the offset would add radial load. Adding bearings would help. I wonder how complicated that would be.

I just heard back from the EV list - someone suggested locking down the axle that doesn't have clearance to prevent it from rotating. (Obviously not connected to the wheel.) I'll have an extra axle, so I can mod/weld anything needed to do that. That will force the diff to send all power to the "free" axle.

But then I thought, won't that cause the free axle to spin at 2x its normal rate?

|

|

|

|

11-25-2007, 10:01 PM

11-25-2007, 10:01 PM

|

#118 (permalink)

|

|

Batman Junior

Join Date: Nov 2007

Location: 1000 Islands, Ontario, Canada

Posts: 22,534

Thanks: 4,082

Thanked 6,979 Times in 3,614 Posts

|

05-28-2006, 08:53 Pm

Some photos of this weekend's work...

click to zoom the little ones...

Swift before (when we still had grand ambitions for repairing its holey underbits) and after its ICE-ectomy. Ivan's first, after which he declared: "It's not a car anymore."

The haul.

This transaxle may have a future in the Blackfly...

Together forever: this is where the sheet metal came from that I brazed into the floor & inner fender walls of the blue car.

Mirror image. The sporty Swift tail lights are driving around somewhere in PA now, on the back of XFI's car.

This evening we spent some time discussing our motor options. I think we're leaning towards using one of the smaller 8 inch pump motors, rather than trying to offset the big motor and/or go with the one-wheel-drive option.

Also disconnected everything on the red car in preparation for swapping its strut/hub/brake assembly over (because it's got firmer springs and bigger brakes). |

|

|

|

11-25-2007, 10:02 PM

11-25-2007, 10:02 PM

|

#119 (permalink)

|

|

Batman Junior

Join Date: Nov 2007

Location: 1000 Islands, Ontario, Canada

Posts: 22,534

Thanks: 4,082

Thanked 6,979 Times in 3,614 Posts

|

SVOboy chimes in ...

Quote:

You're so crazy, I love the mirror image shot.

*jealous*

|

|

|

|

|

11-25-2007, 10:02 PM

11-25-2007, 10:02 PM

|

#120 (permalink)

|

|

Batman Junior

Join Date: Nov 2007

Location: 1000 Islands, Ontario, Canada

Posts: 22,534

Thanks: 4,082

Thanked 6,979 Times in 3,614 Posts

|

05-28-2006, 09:43 Pm

The whole reason we pulled the drivetrain from the red car was to get its transmission mounts and axles. The transaxle in the 4-cyl car is offset further to the left than in the 3-cyl car, and we needed that extra length.

At least that was the plan, when we still thought we were going to be using the forklift's larger 12.5 x 15.5 inch traction motor.

Alas, we discovered the diameter of that motor is too big:

With the motor shaft aligned with the tranny's input shaft, the motor diameter (green line) is actually slightly larger than the outside diameter of the bell housing.

It's big enough that it would interfere with the axle where it connects to the differential (yellow line).

My fault - I never thought to check BEHIND the ICE to measure where the axle hole was (what's the right name for that anyway?).

But it's no big deal. Even if we don't use the big drive motor (and thus the different mounts & axles), I still wanted this transmission out of the red car for the Blackfly. It's geared taller for the 4-cyl motor and would be an interesting FE upgrade.

|

|

|

|

|