I'm converting a 1991 VW Golf to all electric, and planning on some aeromods to extend my range. This is my dream project (well, one of them at least) and I'm having lots of fun so far.

The Future Awesome:

(Side note: You must look at this:

Golf EV Aeromodders rejoice!)

Since I'm planning on adding a belly pan and blocking the grill, I am a little concerned about keeping the controller at the ideal temperature, since you lose efficiency and shorten the lifespan of the controller. That and scalding yourself on a 200 degree controller while showing off to your friends and family how safe and simple an EV is would be a little...crunchy.

My basic approach with this whole project has been to keep it simple (stupid) but also have fun, try new things out, and hopefully get other people interested in EVs as well. In the end I even get a cool car and a big 'FU' to the Oil execs out of the deal.

I'm planning either a 108v or 120v battery bank, depending on my battery shoehorning skillz, a Kelly KDH 120v controller, and a Warp 9 motor, so at max amps on a hot day, my controller could get dangerously hot.

But I had this idea. Its probably a detour from the KISS principle, but I wanted to see if this sounds crazy, or doable.

Heat pipes...

No direct airflow to controller necessary, no pump or voltage drain required. Heat pipes are used in various cooling applications because they are simple, cheap and effective ways to dissipate heat.

The limitations of heat pipes from Wikipedia:

Quote:

Heat pipes must be tuned to particular cooling conditions. The choice of pipe material, size and coolant all have an effect on the optimal temperatures in which heat pipes work.

When heated above a certain temperature, all of the working fluid in the heat pipe will vaporize and the condensation process will cease to occur; in such conditions, the heat pipe's thermal conductivity is effectively reduced to the heat conduction properties of its solid metal casing alone. As most heat pipes are constructed of copper (a metal with high heat conductivity), an overheated heatpipe will generally continue to conduct heat at around 1/80 of the original conductivity.

In addition, below a certain temperature, the working fluid will not undergo phase change, and the thermal conductivity will be reduced to that of the solid metal casing. One of the key criteria for the selection of a working fluid is the desired operational temperature range of the application. The lower temperature limit typically occurs a few degrees above the freezing point of the working fluid.

|

Ok, so I need to figure out my target heat dissipation temperature, the expected average ambient temperature, a working fluid, and what materials to use to make it all work out.

The biggest consideration to start is ambient temp, since I have no control over the weather. At least not yet. The Northwest US is pretty mild weather wise, usually no more than a week or two of extreme cold or heat. 'Heat' around here qualifies as anything above 65-70F. The average temperature is around 45-55F. Extreme cold snaps do happen, but the blocked grill and bellypan help out at that point. The hot months of summer are the main concern.

The

Kelly controller has an upper working temp of something like 120F and a lower temperature of 32F for optimum performance, the extreme ranges being -22F (If it ever gets that cold here, I'll have bigger worries than my voltage controller) to 212F, which, on a hot summer day may be possible for a hard working controller lovingly crafted in China. So lets aim at the safe side of the optimal operating temps, say 65-70 degrees for the target cooling point.

But what if it gets really really hot, or really really cold you ask? Well, there is a vacuum pump already planned for brake assist, why not use the vacuum for something else, since its there already? By installing a nozzle, check valve and a vacuum gauge, you can lower the pressure in the pipes, making the boiling point and target temp reasonably adjustable to varying seasonal averages.

Now, its time to figure out what fluid to use. I just learned about heat pipes recently, so I don't know if there is some Gold Standard Fluid that (duh) everyone uses in their heat pipes, so I'll start with the cheapest idea.

You could use water with a little antifreeze. Never freezes, easy to get, easy to find phase change charts to adjust vacuum, plus it has that attractive slime green color. Downside is that higher temps could boil it to complete vapor. At regular atmosphere, water starts bubbling at 100F, and is a roiling boil at 212F. 100F is too far from our cooling target, assuming vapor is the main workhorse in the heat pipes magic. You would need to introduce vacuum to lower the boiling point to the temperatures you want to maintain. If higher temps do become a problem, you need a larger reservoir of water and larger condenser area.

You could get fancy with temp/pressure sensors, and automatic switches to regulate the pressure to optimize cooling automatically, but thats not cheap, or simple, just cool. Get it? Cool?

Sorry.

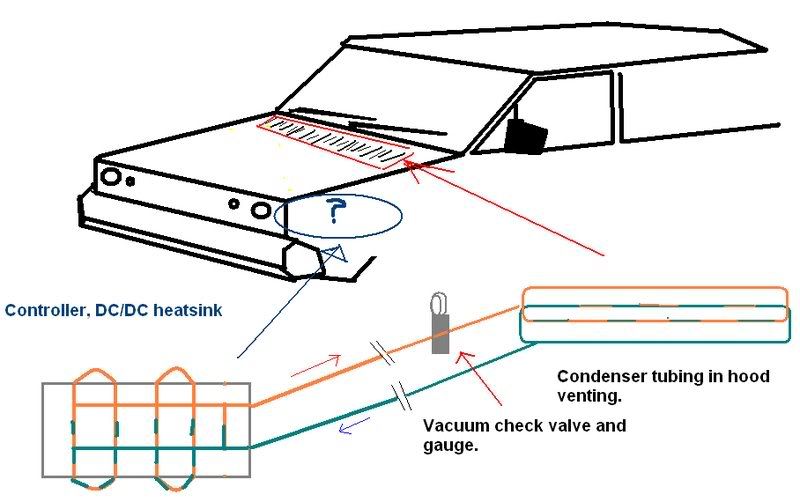

So this is where the materials and design specifics come in. I'm imagining an aluminum block big enough to fit the DC/DC converter (they cook too) and the controller on. Drill a grid of holes through the block, thread the holes and attach fittings to create a heat circuit (does that term even make sense?) then run hose to the condenser portion, basically a bunch of copper tubing or whatever coiled somewhere in airflow. The VW MK2's happen to have a good place for it.

Like so:

Yes, that is MS Paint. Yes, I am a noob.

I think I'll be able to make this pretty cheap, at least cheaper than some of the cooling kits some places are selling for $200+

Any ideas? Hints? Opinions? Reality checks?

Thanks!

(Dear Mods: please feel free to eliminate the mystery double YouTube linky, I don't know whats up with that. Then feel free to erase this message as well!)