08-05-2010, 03:34 PM

08-05-2010, 03:34 PM

|

#61 (permalink)

|

|

The PRC.

Join Date: Oct 2009

Location: Elsewhere.

Posts: 5,304

Thanks: 285

Thanked 536 Times in 384 Posts

|

Quote:

Originally Posted by C3H8

have messed with a potentiometer on my tps. it didn't change my air-fuel ratio's at all, but it did change my ignition timing, if i tricked the computer into thinking the throttle was closed more then it really was. the timing went up a few degrees. it also lowered the rpm's at which the transmission shifted. the torque converter stayed locked up more, and the engine went into open loop under acceleration a lot less (almost never). all good things for FE.

if i went too far though, the engine would surge and lope and a CEL was triggered, so i adjusted it for best economy at 50mph, and took the pot out and replaced it with a perminant resistor.

|

What was the difference between the messing about with the TPS and just pressing the pedal less ?

BTW given previous comments and my own earlier comment about the temp sensor I would like to say this is a genuine question.

Ta.

__________________

[I]So long and thanks for all the fish.[/I]

|

|

|

|

Today Today

|

|

|

|

Other popular topics in this forum...

Other popular topics in this forum...

|

|

|

|

08-06-2010, 10:43 AM

08-06-2010, 10:43 AM

|

#62 (permalink)

|

|

oldschool

Join Date: May 2010

Location: Illinois

Posts: 184

Thanks: 21

Thanked 35 Times in 25 Posts

|

Quote:

Originally Posted by Arragonis

What was the difference between the messing about with the TPS and just pressing the pedal less ?

|

When he says that less TPS% gives him more spark advance, I can deduce that his ECM uses TPS% in the load calculation. The calculated load is used by the main fueling table and main spark table to determine which calibration value to use. Naturally, if he's running closed-loop mode, then the adaptive fueling algorithm will adjust (usually up to plus or minus 25%) fuel-trims to maintain a 14.6:1 AFR. However, if there is no knock retard in effect, the different load value will result in a different spark advance calibration. Generally in the spark advance table the advance calibrations increase as load decreases.

With a TPS tricker this function is independent of actual throttle position and actual VE of the engine.

There are also other tables based on calculated load value that control other functions such as AE - Acceleration Enrichment, transmission shift points (in newer vehicles), and TCC lock-up in automatics. TPS% is also one of the main thresholds for PE - Power Enrichment activation.

How much a TPS tricker can affect engine operation depends on exactly how much the TPS% is factored into the load calculation.

Some algorithms base load factor more heavily on input from the MAP or MAF sensor. In those cases a TPS tricker would prove to be less effective in some functions, and not effective at all in others.

For example, the 1991 Chevy truck listed under my name uses only the delta-MAP input to skew the AFR from my base calibration (VE table) when in open-loop mode. The TPS% is almost a non-factor for calculating VE in that particular ECM. TPS% does determine PE activation, and in the calibration I have my choice of heavily basing the AE on either delta-TPS% or delta-MAP.

Every car model is a little different.

Assuming no change in calculated VE, opening the throttle more will result in an increase in actual VE, which will increase cylinder pressure, burn temperature, and burn speed. Most things being equal, the efficiency will go up, at least for the engine. Whether it helps your MPG or not can depend entirely on how you drive it to take advantage of the situation. For example, If you try to accelerate heavily with increased spark timing, a locked torque converter, and no down-shift, then you're likely to get bad results.

I tried to be thorough.

__________________

#####################################

|

|

|

|

08-06-2010, 11:37 AM

08-06-2010, 11:37 AM

|

#63 (permalink)

|

|

Master EcoModder

Join Date: Feb 2010

Location: CT, USA

Posts: 544

RaceJeep - '98 Jeep Grand Cherokee (ZJ) 5.9 Limited 90 day: 13.62 mpg (US)

Thanks: 1

Thanked 26 Times in 23 Posts

|

Just be aware, by making the tranny think you're stepping on the gas less, it lowers the line pressure, making shifts slower and softer. This can shorten transmission life. However, some adjustments to the tranny and/or a shift kit can easily bring things back in line.

__________________

Call me crazy, but I actually try for mpg with this Jeep:

Typical driving: Back in Rochester for school, driving is 60 - 70% city

|

|

|

|

08-06-2010, 11:59 AM

08-06-2010, 11:59 AM

|

#64 (permalink)

|

|

oldschool

Join Date: May 2010

Location: Illinois

Posts: 184

Thanks: 21

Thanked 35 Times in 25 Posts

|

The updated % gain for today:

Leg#1 +7.04%

Leg#3 +10.26%

...still going up a little.

In a few more days I'm going to call it done and move to the next mod.

__________________

#####################################

|

|

|

|

08-06-2010, 06:25 PM

08-06-2010, 06:25 PM

|

#65 (permalink)

|

|

insane in the propane

Join Date: Jul 2010

Location: palm beach

Posts: 58

Thanks: 3

Thanked 8 Times in 4 Posts

|

Olympiadis, I appreciate you answering Arragonis for me. you did a pretty good job at explaining it. better then I could anyways.

arragonis, thanks for jumping in with a relevant question. I'll expand on Olympiadis's answer and it is quite relevant because using a potentiometer on the tps is close to the same thing as using it on the coolant temp sensor. It works pretty much how Olympiadis said. My car Uses tps, among other things, to determine spark timing. there are a few exceptions, however If i depress the throttle on my car, the ignition timing goes down in value. things that make it increase are the base timing table, (that is rpm dependant) the map sensor, the tps, and the intake air temp sensor, as well as coolant temp sensor. they all play a role in determining how far to deviate from the base (plus or minus) ignition timing table in the computer.

In a real world situation if i am driving steady state at 50mph my ignition timing is about 33 degrees. I depress the throttle petal 1/2 inch, according to the scan gauge the ignition timing retards about 10 degrees, putting me around 23 degrees timing. And at that instant the engine is still at the same rpm and i am at the same mph. Now I also start to accelerate because of increased throttle opening. as i accelerate the ignition timing slowly comes back up.

In another situation, if i am again traveling at 50mph with 33 degrees of timing, and I release the throttle petal, I can watch my ignition timing go from 33 degrees to 34, 35, etc until it peaks about 38-39 degrees, until the rpm's drop enough for the timing to again start backing down.

It's the computerized version of the old fashioned dizzy's that used counterweights, cams and springs to determine timing, along with vacuum advance and retard diaphrams. It's the same thing.

So my goal with the potentiometer on my tps is to 'trick" the computer into thinking my throttle petal is JUST off of idle position. This is where my obd2 scanner shows me that I get maximum ignition timing for my car at pretty much any speed between 0 and 90ish. (and believe me i have thoroughly testes this to be sure because I do not want to make a modification that would result in less mpg) And that is exactly what I did. Now my ignition timing reads about 37 degrees when I am again doing 50mph under steady load. Only difference is, I am getting a bit better mileage now. I noticed that as i slowly turned the pot, my ignition timing slowly went up, and so did my miles per gallon.

keep in mind that you can go too far with ign timing. I was able to make the car ping like a dozen marbles in a tin can if i cranked the tps down too much. I also got the same effect when I messed with the MAP sensor and went too far. also it is possible to go too far with ignition timing, and not expierence pinging, yet you can expierence DECREASED fuel economy with too far advanced timing by having the combustion pressure peak too early in the cylinder's cycle. I don't quite remember exactly where combustion should peak in terms of degrees of rotation for maximum efficiency, but i am guessing it is somwhere around 15 degrees after top dead centre.

I have not got my timing to go that far, yet. My car just pings when it goes too high for the load I am putting on it.

for instance, at night when it is 30 degrees cooler, I am able to run a bit higher ignition timing and get away with it without pinging or decreased mileage. That is too finisky for me though, so I generally keep the timing set to daytime use and leave it there. I might screw around with drastic timing changes when winter comes, though.

I have heard of other brands of cars which have different timing needs. Me mum's honda crv has over 40 degrees of timing right out of the factory under steady load cruising around and does not ping at all. And i have not screwed around with the crv's timing by the way. It also does not have egr but it does have higher compression ratio then me dodge. It also has a drastically higher horsepower to CC rating them my engine too. So I guess the honda is a better design. Fancy that.

My point is, different engines need different ignition timing settings.

Edit: One other thing I forgot to mention. I have heard of certain cars that do not use some sensors for setting ignition timing. Most noticably would be the air temp sensor. I have seen some turbo mitsubishi's that do not care what the air temp sensor says concerning timing. they use that sensor for other things I guess. I believe that OBD1 miata's only use tps to tell the computer if it should be in open loop or closed loop and have nothing really to do with timing) but I could be wrong. My point in this edit is that although MY engine appears to use air, coolant, map and tps for timing, not all engines do. so if one of you guys decide to screw around and try to increase timing and it DOESN'T work, try another sensor.

If you're screwing around causes a change in fueling, the oxygen sensor will probably correct it shortly. the obd2 cars have short and long term fuel trims. short term is quick. My car can add or subtract up to 25% of the fuel from being injected almost instantly. (I tested this with a big propane torch).

My engine's long term fuel trim is also capable of subtracting an ADDITIONAL 25% of the fuel. I also determined that with propane, but it was from an earlier test via literally flooring the motor with a 20lb propane tank while driving down the highway. I just wanted to see what the computer was capable of dealing with, and yeah it can actually subtract about 50% of it's injector duty cycle and still maintain proper o2 sensor voltages (dancing from 0.1V to 0.9V) but thats another subject for another time...

__________________

96 stratus "es" v6 auto-stick

supplementary propane injection

injector kill switch, alternator kill switch

Charging system voltage increased to 15.5V

secondary and tertiary 12v batteries in the trunk

on-board battery charger

lights converted to led's

potentiometer controlled tps for ign timing

welded straight pipe in place of cat-cons

removed egr

3 inch body drop

90psi fuel rail & -50% low volume injectors

run 15% diesel 85% gas

Last edited by C3H8; 08-06-2010 at 06:36 PM..

|

|

|

|

08-06-2010, 06:53 PM

08-06-2010, 06:53 PM

|

#66 (permalink)

|

|

insane in the propane

Join Date: Jul 2010

Location: palm beach

Posts: 58

Thanks: 3

Thanked 8 Times in 4 Posts

|

Quote:

Originally Posted by comptiger5000

Just be aware, by making the tranny think you're stepping on the gas less, it lowers the line pressure, making shifts slower and softer. This can shorten transmission life. However, some adjustments to the tranny and/or a shift kit can easily bring things back in line.

|

You bring up a good point. for manual transmissions, this obviously doesn't metter. Some automatics, praticularly earlier ones with not so smart computers controlling them, may have a problem with this. I don't know as I have never had a stupid automatic. What I do have, is a manumatic with the chrysler a604 tranny. It's not the most durable tranny in the world but it does come stock on some turbo cars, and v8's with a lot more power them my measly 170hp v6. My a604 is also smart, well as far as car computers go anyways. It was one of the first fully computer controlled automatics in existance. no kickdowncables from the throttle were ever used on this trans even back in the 80. also it never had vaccum lines routed from the intake manifold to the trans to aide in shifting or mile pressure. The computer is in full control and determins when to shift based on rpm's, engine load, transmission temp, etc. I would imagine that modifying the tps to trick the transmission's computer into shifting it while the engine is at a lower rpm and load it probably easier on the clutches. I do have a trans star shift kit installed which I believe increases line pressure. But I don't think that is a requirement for lower rpm shifting as my manumatic trans has a mode in which I can manually shift it, at ANY rpm I want. I can even take off in 3rd gear if i want to. So in a nutshell, if the computer allows me to manually shift it at a low rpm, then it should be ok for me to let the computer take control and shift it at the same, low, rpm.

__________________

96 stratus "es" v6 auto-stick

supplementary propane injection

injector kill switch, alternator kill switch

Charging system voltage increased to 15.5V

secondary and tertiary 12v batteries in the trunk

on-board battery charger

lights converted to led's

potentiometer controlled tps for ign timing

welded straight pipe in place of cat-cons

removed egr

3 inch body drop

90psi fuel rail & -50% low volume injectors

run 15% diesel 85% gas

|

|

|

|

08-06-2010, 09:54 PM

08-06-2010, 09:54 PM

|

#67 (permalink)

|

|

Master EcoModder

Join Date: Feb 2010

Location: CT, USA

Posts: 544

RaceJeep - '98 Jeep Grand Cherokee (ZJ) 5.9 Limited 90 day: 13.62 mpg (US)

Thanks: 1

Thanked 26 Times in 23 Posts

|

With the shift kit in, you've upped the line pressure at any given point in the curve, so the lower line pressure (lower on the curve) when it thinks you're being lighter on the gas isn't dropping the line pressure enough to hurt it.

What can happen (and would if I loosened up the kickdown cable on my Jeep with a 46RE [A518] tranny) is that it shifts too gently and the clutches slip excessively during the shift, wearing them out prematurely. A shift kit ups the line pressure curve, allowing you to sit lower on the curve, giving lower shift points, and still have stock or higher line pressure for a given throttle opening, allowing better mpg without killing the tranny.

__________________

Call me crazy, but I actually try for mpg with this Jeep:

Typical driving: Back in Rochester for school, driving is 60 - 70% city

|

|

|

|

|

The Following User Says Thank You to comptiger5000 For This Useful Post:

|

|

08-07-2010, 09:27 AM

08-07-2010, 09:27 AM

|

#68 (permalink)

|

|

EcoModding Apprentice

Join Date: Jun 2010

Location: New York

Posts: 239

Thanks: 0

Thanked 17 Times in 15 Posts

|

The biggest thing TPS should do is throttle acceleration enrichment , (giving more fuel when you hit the gas).

You sure the TPS is changing timing and not map signal (more load), to make sure or test what TPS does on its own try an remove TPS from throttlebody. Then you have move TPS signal voltage separate from throttle to monitor changes .

|

|

|

|

08-10-2010, 09:06 AM

08-10-2010, 09:06 AM

|

#69 (permalink)

|

|

oldschool

Join Date: May 2010

Location: Illinois

Posts: 184

Thanks: 21

Thanked 35 Times in 25 Posts

|

I'm calling an end to the CTS-tricker test on the Focus.

Gains so far comparing 7 new data points to 8 previous data points.

Leg #1 +6.53% MPG

Leg #3 +9.85% MPG

Overall gain for all driving: +5.25%

Notes:

The CTS tricker has made a big improvement in idle speed and idle fuel usage while coasting and while stopped, when activated 10 to 15 seconds after a cold start and left activated throughout my commute route.

In the time period up to 1.5 minutes immediately after activation I have noticed a few slight lean stumbles when beginning an acceleration.

This is due to the reduced fuel delivery via the main fueling table, reduced AE, reduced spark advance, and mainly due to the fact that the spark plugs and combustion chambers have not warmed to an acceptable point (evaporation of liquid fuel problem). After the 1.5 minute mark and a very short acceleration, the plugs are warm enough to experience no noticeable misfires/stumbles. The slight stumbles noticed were well within what I considered acceptable and if not for Scangauge2 feedback data, would serve as verification that the CTS-tricker was activated and functioning as intended by changing the engine tune parameters and reducing fuel consumption.

I know from previous experience that in colder weather the setting on the CTS-tricker must be increased more gradually up to about the 2 minute mark.

That is, instead of going from actual 75*F cold-start almost immediately (10 to 15 seconds delay) up to 225*F on the CTS-tricker as I have been doing for these tests, a cold start at 30*F may require you to first go to a setting of 80*F -to- 100*F to avoid an unacceptable number of lean misfires, and then on up to 200*F+ around the 2.0 minute mark - or so depending on each individual vehicle and situation. Having the potentiometer for adjustment allows several adjustments at a gradual rate if you desire or need. With the use of a block heater and/or warm-air-intake, the rate can be increased.

__________________

#####################################

|

|

|

|

09-10-2010, 03:53 PM

09-10-2010, 03:53 PM

|

#70 (permalink)

|

|

oldschool

Join Date: May 2010

Location: Illinois

Posts: 184

Thanks: 21

Thanked 35 Times in 25 Posts

|

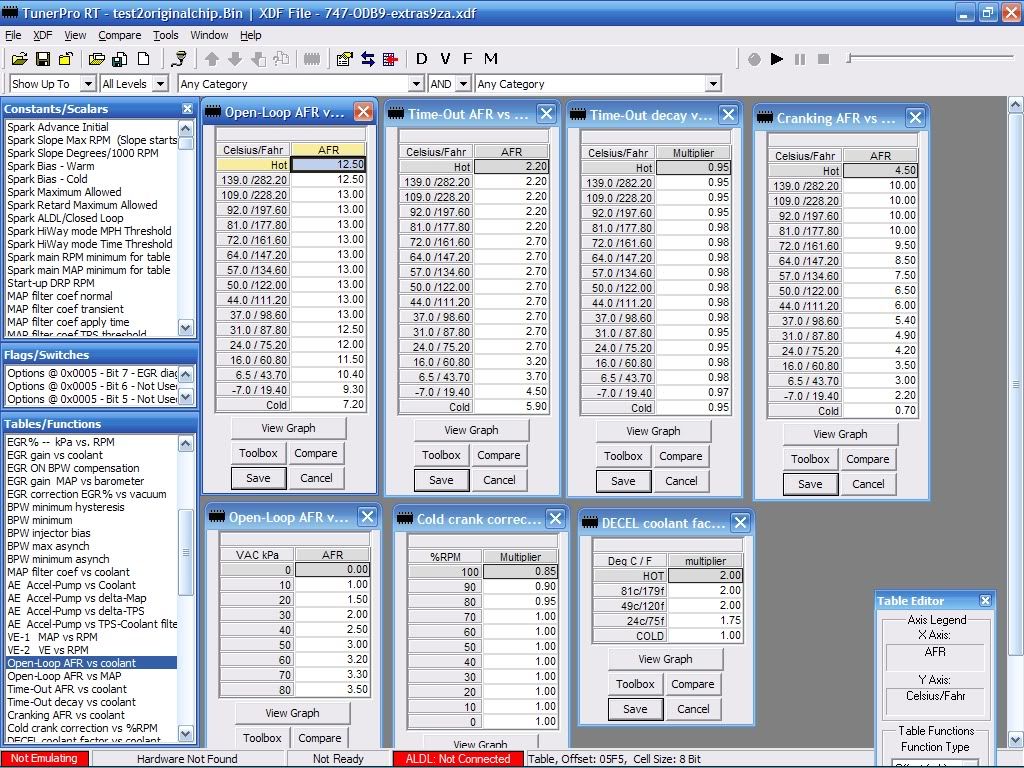

As a visual example, I'm posting a screen-shot of some calibrations from my 1991 Chevy truck.

It clearly shows the calibrations that command extra fueling when the coolant temp sensor (CTS) reads a low temperature.

http://i702.photobucket.com/albums/w...FRscreen1a.jpg

|

|

|

|

|