08-31-2010, 07:11 AM

08-31-2010, 07:11 AM

|

#161 (permalink)

|

|

Administrator

Join Date: Dec 2007

Location: Germantown, WI

Posts: 11,203

Thanks: 2,501

Thanked 2,589 Times in 1,555 Posts

|

The converter is halfway down the car. I'd have to run some fairly long piping. If it were simply off the manifold as most newer cars are I'd agree that would be a better option. Also, if the EGR is bypassing the throttle and there is a small amount of O2 in it, thats not a problem and might even be a good thing as I can actually use that to lower pumping losses even further by using more EGR.

|

|

|

|

|

The Following User Says Thank You to Daox For This Useful Post:

|

|

Today Today

|

|

|

|

Other popular topics in this forum...

Other popular topics in this forum...

|

|

|

|

09-01-2010, 12:40 AM

09-01-2010, 12:40 AM

|

#162 (permalink)

|

|

Master EcoModder

Join Date: Jul 2009

Location: New York

Posts: 513

Thanks: 2

Thanked 101 Times in 74 Posts

|

EGR gases before the cat

Quote:

Originally Posted by Daox

The converter is halfway down the car. I'd have to run some fairly long piping. If it were simply off the manifold as most newer cars are I'd agree that would be a better option. Also, if the

EGR is bypassing the throttle and there is a small amount of O2 in it,

thats not a problem and might even be a good thing as I can actually use that to lower pumping losses even further by using more EGR.

|

exhaust gases before the cat are going to have 1% or more 02 and measurable amounts of CO and HC .

that constitutes air fuel mixture , albeit in very small amounts .

intake air temp sensor would see increased temperature from EGR .

due to the extra heat ,

i do not think it would be a good idea to add EGR before the throttle body , no current car manufacturer does that , that i know of

and

some like GM 3800 s have heat related failures / problems related to EGR flow in the intake manifold .

Cool ed EGR gases from downstream would help to resolve heat related problems |

|

|

|

09-01-2010, 08:32 AM

09-01-2010, 08:32 AM

|

#163 (permalink)

|

|

Administrator

Join Date: Dec 2007

Location: Germantown, WI

Posts: 11,203

Thanks: 2,501

Thanked 2,589 Times in 1,555 Posts

|

In my case, the intake air temp sensor is upstream of the throttle, so it would not see the increase in temp from the EGR. I'm thinking this is a good thing as I want to advance timing as EGR flow increases due to slower flame speed. If the intake temp sensor sees an increase in air temp it may retard timing. That is my thought at least. Input on this would be good.

The EGR will be added directly after the throttle body. This is the location that Toyota adds the EGR. I thought I mentioned that, but now its clarified.

The EGR will be cooled by the TDI EGR cooler. Its a slightly more complex setup, but not really that much more. With the cooler being on the right side of the engine, I have a heater line right there to tap into. I just need to buy one short piece of hose (or dig through my hoses to see if I have one the right size). By cooling the EGR with the TDI cooler, I also ensure that temps will be more consistent and also that there won't be any condensation.

Last edited by Daox; 09-01-2010 at 08:39 AM..

|

|

|

|

09-10-2010, 01:52 PM

09-10-2010, 01:52 PM

|

#164 (permalink)

|

|

oldschool

Join Date: May 2010

Location: Illinois

Posts: 184

Thanks: 21

Thanked 35 Times in 25 Posts

|

Some notes/info about EGR.

The EGR system was neither designed for nor intended to reduce pumping loss.

Most pumping loss due to the engine generating pressure drop is created at the valve and not at the throttle. In fact reversion reduces a significant portion of the pressure drop inside a shared intake manifold plenum.

It is also fact that the engine must physically move more total mass in and out of the cylinder during EGR operation.

Further, EGR contaminates/dilutes the intake charge, and by design reduces burn speed, and therefor efficiency in the chamber. This reduction in burn speed is normally accompanied by an increase in spark advance during EGR operation. The need for starting the spark earlier signifies the loss of burn efficiency due to lower peak cylinder pressures around TDC. At the same time there is increased cylinder pressure earlier in the cycle before TDC, which in turn requires more energy to complete the compression stroke. This situation is less efficient than a quicker burning intake charge with the spark started later in the cycle. In driving situations where more engine power is required, EGR reduces both engine efficiency and vehicle fuel efficiency. This wouldn't be so bad except for the fact that the EGR algorithm is factory programmed to deliver the EGR charge during times of needed power production. In fact up to a point, the more power that is asked of the engine, the more EGR is delivered. This is no accident in that asking the engine to produce power increases the VE, cylinder pressure, burn speed, and BSFC of the engine, but as a side effect also creates conditions for increased NOX production.

The EGR system was neither designed nor intended to increase fuel economy. It (EGR) was designed to reduce NOX production as efficiently as possible, - to mean being effective and having as minimal effect on overall fuel economy as possible. The design engineers did a fairly good job of this within the constraints of keeping the system relatively cheap and simple. Their result is a system that does not negatively affect fuel economy or power for a fairly wide range of engine operation. This qualifier is not to be confused with "the entire range of engine operation", nor is it meant to infer that the operation of the EGR system can't result in an overall loss in fuel economy (as factory programmed). It also doesn't mean that the functioning EGR system (even when functioning properly) can't result in several other negative effects to the engine that increase the overall cost of vehicle operation. I recondition cylinder heads in my shop, but I'm not going to go into details along the lines of the negative effects of EGR. Basically the effects are similar to other conditions that cause inefficient/slower burn in the chambers.

A slower burn in the chamber means that less energy from the fuel can be converted into motion energy, which often results in more heat rejected into the cooling system. One can test and measure this effect by reducing your spark advance and monitoring coolant temp and EGT. EGR operation includes an increase in spark advance that mitigates this heat rejection problem during the BTDC phase of the burn cycle, but increases resistance to the upward moving piston by doing so.

There are points of diminishing returns for the amount of EGR delivered in respect to reduced engine efficiency and reduced thermal efficiency. Out of all the factory calibrations that I've seen, 35% is the highest amount of EGR delivery applied. This isn't to say that you can't get away with more, or change the conditions so that you can get away with significantly more. How to apply this possibility is the question. I'll try to offer a helpful suggestion.

In that it reduces engine power, EGR is similar to a modification like the WAI - warm/hot air induction. If you study the WAI performance closely you will see that a reduction in engine power can improve your vehicle fuel efficiency during times when you can get away with less power production from the engine. If you need the power, then a modification like this is going to hurt your vehicle fuel efficiency. Most people don't realize this because they use a mix of driving conditions during their testing. I have thoroughly tested both EGR and WAI back in the early 1990's.

My results are as follows:

WAI tested on wet-flow (TBI) systems:

unloaded driving +9.5% MPG

loaded driving -16.6% MPG

WAI tested on dry-flow (MPFI) systems:

unloaded driving +1.1% MPG

loaded driving -8.3% MPG

WAI overall mixed conditions with wet-flow systems (TBI) +7.3%

EGR tested on wet-flow (TBI) systems:

unloaded driving +3.9%

loaded driving -1.6%

EGR overall mixed conditions with wet-flow (TBI) -1.5%

In tests of a dozen different vehicles I have always seen a small reduction in overall fuel mileage with the use of EGR. In testing WAI in about the same amount of different vehicles I always see between 0% and around 10% overall gain in MPG depending on the fueling system (wet or dry), and depending on how over-powered or under-powered the vehicle/engine combination is.

Since EGR and WAI have a somewhat similar effect, then why the big discrepancy in MPG during mixed driving conditions between the two strategies? Well, that is explained by the factory ECM calibrations and logic that control EGR operation. Instead of delivering the EGR to the engine during times of unloaded driving, the logic does the opposite. As explained earlier, the need to reduce NOX comes at a time when engine efficiency would normally be high - when you are asking power of the engine. Therefor the factory algorithm delivers the EGR during partial loading conditions when you are accelerating (not WOT or PE mode), or cruising steadily at a moderate load. When you are at very light loads or in DECEL conditions, most algorithms stop the flow of EGR. My test results of EGR stated above were not from hypermiling, so naturally there is more to be gained and less to be lost from EGR if you hypermile - due to the lower % engine loading time.

With hypermiling, the best I've seen personally with EGR vs no-EGR is to break even on the overall MPG. That's not to say that some vehicle combinations and/or calibrations do not result in increased MPG with the use of EGR. I can see how that could very well happen given certain conditions. I've just not experienced them myself. I'm certainly not discouraging you from trying to improve MPG using an EGR system.

Based on this information, my suggestion is to basically reverse the condition thresholds for EGR operation so that you get less or none during engine loading, and more during light load/DECEL. At light load and steady throttle I don't see why you couldn't get away with 50% EGR or more, and Scangauge + datalogging should show you the point where you lose any MPG advantage that you may find. I'm very interested to see the results.

If you don't mind I will post some calibration/algorithm data, and some screen-shots of the EGR calibrations from my 1991 Chevy p/u. They may give you some insight into the system strategy that the factory set up. It will be the stock calibrations shown to avoid confusion. I modified the EGR algorithm on my truck to run the electric cooling fan instead of the EGR.

__________________

#####################################

Last edited by Olympiadis; 09-10-2010 at 02:01 PM..

|

|

|

|

09-10-2010, 02:45 PM

09-10-2010, 02:45 PM

|

#165 (permalink)

|

|

oldschool

Join Date: May 2010

Location: Illinois

Posts: 184

Thanks: 21

Thanked 35 Times in 25 Posts

|

EGR calibration

First part of calibration/constants section:

Quote:

;================================================= ============

; EGR PARAMETERS

;================================================= ============

LD1B3 FCB 132 ; 48c/119f COOLANT FOR EGR ENABLE (L00E3 INVERSE COOLANT)

LD1B4 FCB 0 ; 0 MPH LO VSS THRESHOLD FOR EGR ENABLE

LD1B5 FCB 0 ; 0 MPH HI VSS THRESHOLD FOR EGR ENABLE

LD1B6 FCB 5 ; 2%, LO TPS FOR EGR ENABLE

LD1B7 FCB 8 ; 3%, HI TPS FOR EGR ENABLE

LD1B8 FCB 48 ; 35 Kpa MAP, LO VACUUM FOR EGR ENABLE

LD1B9 FCB 56 ; 38 Kpa MAP, HI VACUUM FOR EGR ENABLE

LD1BA FCB 255 ; 0.9960 SPARK COEF FOR EGR OFF SPARK FILTER

LD1BB FCB 16 ; 0.0625 SPARK COEF FOR EGR ON SPARK FILTER

LD1BC FCB 230 ; 0.898 EGR D.C. (duty cycle) FILTER COEF

LD1BD FCB 51 ; 19.9% D.C. (duty cycle) THRESHOLD FOR EGR ON

LD1BE FCB 254 ; 1 Kpa VACUUM THRESHOLD FOR EGR ON, (104 Kpa)

LD1BF FCB 128 ; 50% TPS HI TPS THRESHOLD FOR EGR -AFTER 50% GAIN = 0

;-----------------------------------------

;---------------------------------------------

; PERCENT EGR vs VACUUM-LOAD vs RPM

; 7 COL x 7 BLOCKS = 49 BYTES TABLE = 2.56 * EGR%

ORG $01C0 ;---------------------------------------------

LD1C0 FCB 0 ; LOAD SELECT 0 = VACUUM, 1 = MAP

ORG $01C1 ; TABLE LIMITS

LD1C1 FCB 80 ; 1000 RPM MINIMUM RPM VALUE (80 * 12.5) = 1000

LD1C2 FCB 32 ; 40 KPA MINIMUM MAP VALUE ((32 * 0.626) +20) = 40.032

LD1C3 FCB 7 ; LINES/BLOCK

;---------------------------------------------

; 1000 RPM EGR % MAP

;---------------------------------------------

LD1C4 FCB 255 ; 99.6 40

LD1C5 FCB 255 ; 99.6 50

LD1C6 FCB 255 ; 99.6 60

LD1C7 FCB 255 ; 99.6 70

LD1C8 FCB 255 ; 99.6 80

LD1C9 FCB 255 ; 99.6 90

LD1CA FCB 255 ; 99.6 100

;---------------------------------------------

; 1200 RPM EGR % MAP

;---------------------------------------------

LD1CB FCB 255 ; 99.6 40

LD1CC FCB 255 ; 99.6 50

LD1CD FCB 255 ; 99.6 60

LD1CE FCB 255 ; 99.6 70

LD1CF FCB 255 ; 99.6 80

LD1D0 FCB 255 ; 99.6 90

LD1D1 FCB 255 ; 99.6 100

;---------------------------------------------

; 1400 RPM EGR % MAP

;---------------------------------------------

LD1D2 FCB 255 ; 99.6 40

LD1D3 FCB 255 ; 99.6 50

LD1D4 FCB 255 ; 99.6 60

LD1D5 FCB 255 ; 99.6 70

LD1D6 FCB 255 ; 99.6 80

LD1D7 FCB 255 ; 99.6 90

LD1D8 FCB 255 ; 99.6 100

;---------------------------------------------

; 1600 RPM EGR % MAP

;---------------------------------------------

LD1D9 FCB 255 ; 99.6 40

LD1DA FCB 255 ; 99.6 50

LD1DB FCB 255 ; 99.6 60

LD1DC FCB 255 ; 99.6 70

LD1DD FCB 255 ; 99.6 80

LD1DE FCB 255 ; 99.6 90

LD1DF FCB 255 ; 99.6 100

;---------------------------------------------

; 1800 RPM EGR % MAP

;---------------------------------------------

LD1E0 FCB 255 ; 99.6 40

LD1E1 FCB 255 ; 99.6 50

LD1E2 FCB 255 ; 99.6 60

LD1E3 FCB 255 ; 99.6 70

LD1E4 FCB 255 ; 99.6 80

LD1E5 FCB 255 ; 99.6 90

LD1E6 FCB 255 ; 99.6 100

;---------------------------------------------

; 2200 RPM EGR % MAP

;---------------------------------------------

LD1E7 FCB 255 ; 99.6 40

LD1E8 FCB 255 ; 99.6 50

LD1E9 FCB 255 ; 99.6 60

LD1EA FCB 255 ; 99.6 70

LD1EB FCB 255 ; 99.6 80

LD1EC FCB 255 ; 99.6 90

LD1ED FCB 255 ; 99.6 100

;---------------------------------------------

; 3000 RPM EGR % MAP

;---------------------------------------------

LD1EE FCB 255 ; 99.6 40

LD1EF FCB 255 ; 99.6 50

LD1F0 FCB 255 ; 99.6 60

LD1F1 FCB 255 ; 99.6 70

LD1F2 FCB 255 ; 99.6 80

LD1F3 FCB 255 ; 99.6 90

LD1F4 FCB 255 ; 99.6 100

;---------------------------------------------

|

|

|

|

|

09-10-2010, 02:47 PM

09-10-2010, 02:47 PM

|

#166 (permalink)

|

|

oldschool

Join Date: May 2010

Location: Illinois

Posts: 184

Thanks: 21

Thanked 35 Times in 25 Posts

|

continued:

Quote:

;-------------------------------------

; EGR GAIN vs COOLANT VALUE = N * 128

;-------------------------------------

LD1F5 FCB 152 ; 90C/194F, UPPER TABLE LIMIT

ORG $01F6 ; GAIN Deg c

;---------------------------------

LD1F6 FCB 128 ; 1.00 20

LD1F7 FCB 128 ; 1.00 30

LD1F8 FCB 128 ; 1.00 40

LD1F9 FCB 128 ; 1.00 50

LD1FA FCB 128 ; 1.00 60

LD1FB FCB 128 ; 1.00 70

LD1FC FCB 128 ; 1.00 80

LD1FD FCB 128 ; 1.00 90

;---------------------------------

;-------------------------------------

; EGR GAIN FACTOR vs BAROMETER & MAP

; 7 COL x 7 BLOCKS = 49 BYTES TABLE = 128 * Gain

;-------------------------------------

ORG $01FE ; TABLE LIMITS

LD1FE FCB 32 ; 40 KPA MINIMUM MAP Value ((32 * 0.626) +20) = 40.032

LD1FF FCB 96 ; 75 KPA MINIMUM BAROMETER ((96 * 0.626) +15.2) = 75.296

LD200 FCB 4 ; LINES/BLOCK

;---------------------------------------------

; 40 KPA MAP Gain Kpa BARO

;---------------------------------------------

LD201 FCB 123 ; 0.96 75

LD202 FCB 128 ; 1.00 80

LD203 FCB 128 ; 1.00 85

LD204 FCB 128 ; 1.00 90

;---------------------------------------------

; 50 KPA MAP Gain Kpa BARO

;---------------------------------------------

LD205 FCB 128 ; 1.00 75

LD206 FCB 128 ; 1.00 80

LD207 FCB 128 ; 1.00 85

LD208 FCB 128 ; 1.00 90

;---------------------------------------------

; 60 KPA MAP Gain Kpa BARO

;---------------------------------------------

LD209 FCB 128 ; 1.00 75

LD20A FCB 128 ; 1.00 80

LD20B FCB 128 ; 1.00 85

LD20C FCB 128 ; 1.00 90

;---------------------------------------------

; 70 KPA MAP Gain Kpa BARO

;---------------------------------------------

LD20D FCB 128 ; 1.00 75

LD20E FCB 128 ; 1.00 80

LD20F FCB 128 ; 1.00 85

LD210 FCB 128 ; 1.00 90

;---------------------------------------------

; 80 KPA MAP Gain Kpa BARO

;---------------------------------------------

LD211 FCB 128 ; 1.00 75

LD212 FCB 128 ; 1.00 80

LD213 FCB 128 ; 1.00 85

LD214 FCB 128 ; 1.00 90

;---------------------------------------------

; 90 KPA MAP Gain Kpa BARO

;---------------------------------------------

LD215 FCB 128 ; 1.00 75

LD216 FCB 128 ; 1.00 80

LD217 FCB 128 ; 1.00 85

LD218 FCB 128 ; 1.00 90

;---------------------------------------------

; 100 KPA MAP Gain Kpa BARO

;---------------------------------------------

LD219 FCB 128 ; 1.00 75

LD21A FCB 128 ; 1.00 80

LD21B FCB 128 ; 1.00 85

LD21C FCB 128 ; 1.00 90

;---------------------------------------------

;-------------------------------------

; 454cid DIFF VALUES - NO EVEN SPACING

; IN NUMBER VALUE 0, 16, 32 HEADER ARE SAME

;-------------------------------------

; EGR CORRECTION Vs. VACUUM Vs. EGR D.C.

; 02-01-2000 Dissassemby of ARJU

; 13 COL x 8 BLOCKS = 104 BYTES

; TABLE = 2.56 * MULT %

;-------------------------------------

ORG $021D ; CORRECTION TO AIR FLOW FOR EGR SPARK ADV

LD21D FCB 48 ; MIN KPA VACUUM Value

LD21E FCB 0 ; Min % EGR Value

LD21F FCB 13 ; LINES/BLOCK

;---------------------------------------------

; 30 % EGR MULT % KPA VAC

;---------------------------------------------

LD220 FCB 0 ; 0.0 0.0

LD221 FCB 16 ; 6.3 2.5

LD222 FCB 32 ; 12.5 5.0

LD223 FCB 48 ; 18.8 7.5

LD224 FCB 64 ; 25.0 10.0

LD225 FCB 80 ; 31.3 12.5

LD226 FCB 96 ; 37.5 15.0

LD227 FCB 112 ; 43.8 17.5

LD228 FCB 128 ; 50.0 20.0

LD229 FCB 144 ; 56.3 30.0

LD22A FCB 160 ; 62.5 40.0

LD22B FCB 176 ; 68.8 50.0

LD22C FCB 192 ; 75.0 60.0

;---------------------------------------------

; 40 % EGR MULT % KPA VAC

;---------------------------------------------

LD22D FCB 0 ; 0.0 0.0

LD22E FCB 16 ; 6.3 2.5

LD22F FCB 32 ; 12.5 5.0

LD230 FCB 48 ; 18.8 7.5

LD231 FCB 64 ; 25.0 10.0

LD232 FCB 80 ; 31.3 12.5

LD233 FCB 96 ; 37.5 15.0

LD234 FCB 112 ; 43.8 17.5

LD235 FCB 128 ; 50.0 20.0

LD236 FCB 144 ; 56.3 30.0

LD237 FCB 160 ; 62.5 40.0

LD238 FCB 176 ; 68.8 50.0

LD239 FCB 192 ; 75.0 60.0

;---------------------------------------------

; 50 % EGR MULT % KPA VAC

;---------------------------------------------

LD23A FCB 0 ; 0.0 0.0

LD23B FCB 16 ; 6.3 2.5

LD23C FCB 32 ; 12.5 5.0

LD23D FCB 48 ; 18.8 7.5

LD23E FCB 64 ; 25.0 10.0

LD23F FCB 80 ; 31.3 12.5

LD240 FCB 96 ; 37.5 15.0

LD241 FCB 112 ; 43.8 17.5

LD242 FCB 128 ; 50.0 20.0

LD243 FCB 144 ; 56.3 30.0

LD244 FCB 160 ; 62.5 40.0

LD245 FCB 176 ; 68.8 50.0

LD246 FCB 192 ; 75.0 60.0

;---------------------------------------------

; 60 % EGR MULT % KPA VAC

;---------------------------------------------

LD247 FCB 0 ; 0.0 0.0

LD248 FCB 16 ; 6.3 2.5

LD249 FCB 32 ; 12.5 5.0

LD24A FCB 48 ; 18.8 7.5

LD24B FCB 64 ; 25.0 10.0

LD24C FCB 80 ; 31.3 12.5

LD24D FCB 96 ; 37.5 15.0

LD24E FCB 112 ; 43.8 17.5

LD24F FCB 128 ; 50.0 20.0

LD250 FCB 144 ; 56.3 30.0

LD251 FCB 160 ; 62.5 40.0

LD252 FCB 176 ; 68.8 50.0

LD253 FCB 192 ; 75.0 60.0

;---------------------------------------------

; 70 % EGR MULT % KPA VAC

;---------------------------------------------

LD254 FCB 0 ; 0.0 0.0

LD255 FCB 16 ; 6.3 2.5

LD256 FCB 32 ; 12.5 5.0

LD257 FCB 48 ; 18.8 7.5

LD258 FCB 64 ; 25.0 10.0

LD259 FCB 80 ; 31.3 12.5

LD25A FCB 96 ; 37.5 15.0

LD25B FCB 112 ; 43.8 17.5

LD25C FCB 128 ; 50.0 20.0

LD25D FCB 144 ; 56.3 30.0

LD25E FCB 160 ; 62.5 40.0

LD25F FCB 176 ; 68.8 50.0

LD260 FCB 192 ; 75.0 60.0

;---------------------------------------------

; 80 % EGR MULT % KPA VAC

;---------------------------------------------

LD261 FCB 0 ; 0.0 0.0

LD262 FCB 16 ; 6.3 2.5

LD263 FCB 32 ; 12.5 5.0

LD264 FCB 48 ; 18.8 7.5

LD265 FCB 64 ; 25.0 10.0

LD266 FCB 80 ; 31.3 12.5

LD267 FCB 96 ; 37.5 15.0

LD268 FCB 112 ; 43.8 17.5

LD269 FCB 128 ; 50.0 20.0

LD26A FCB 144 ; 56.3 30.0

LD26B FCB 160 ; 62.5 40.0

LD26C FCB 176 ; 68.8 50.0

LD26D FCB 192 ; 75.0 60.0

;---------------------------------------------

; 90 % EGR MULT % KPA VAC

;---------------------------------------------

LD26E FCB 0 ; 0.0 0.0

LD26F FCB 16 ; 6.3 2.5

LD270 FCB 32 ; 12.5 5.0

LD271 FCB 48 ; 18.8 7.5

LD272 FCB 64 ; 25.0 10.0

LD273 FCB 80 ; 31.3 12.5

LD274 FCB 96 ; 37.5 15.0

LD275 FCB 112 ; 43.8 17.5

LD276 FCB 128 ; 50.0 20.0

LD277 FCB 144 ; 56.3 30.0

LD278 FCB 160 ; 62.5 40.0

LD279 FCB 176 ; 68.8 50.0

LD27A FCB 192 ; 75.0 60.0

;---------------------------------------------

; 100 % EGR MULT % KPA VAC

;---------------------------------------------

LD27B FCB 0 ; 0.0 0.0

LD27C FCB 16 ; 6.3 2.5

LD27D FCB 32 ; 12.5 5.0

LD27E FCB 48 ; 18.8 7.5

LD27F FCB 64 ; 25.0 10.0

LD280 FCB 80 ; 31.3 12.5

LD281 FCB 96 ; 37.5 15.0

LD282 FCB 112 ; 43.8 17.5

LD283 FCB 128 ; 50.0 20.0

LD284 FCB 144 ; 56.3 30.0

LD285 FCB 160 ; 62.5 40.0

LD286 FCB 176 ; 68.8 50.0

LD287 FCB 192 ; 75.0 60.0

;---------------------------------------------

________________________________________

;---------------------------------------------

; ASDZ INJECTOR FLOW COEF, VALUES FOR 5.7L TBI

;---------------------------------------------

LD2B4 FCB 135 ; BPW constant for EGR off, LD2B4 Constant used for fuel

; BPW when EGR off. If EGR on, table LD324 gives a different

; constant vs Vacuum for EGR compensation. During EGR transients

; the value is filtered between the two constants for smoothing

;-----------------------------------------

; TBI Value = 1461.5 * (VOL/RATE)

; VOL = Vol of 1 Cylinder in liters, (0.7125l)

; RATE = Injector flow in grams/sec

; 5.7l = 7.71 grams/sec (61.2#/HR)

; (VOL/RATE) = 0.0924 l/gm/sec

; PFI Value = 365.375 * (VOL/RATE)

; VOL = Vol of 1 Cylinder in liters, (0.7125l)

; RATE = Injector flow in grams/sec

; 5.7L = 1.92751 grams/sec (#/HR)

; (VOL/RATE) = 0.3696 l/gm/sec

; LD2B4 BPW = 135

;------------------------------------------

; EC PFI Value = 365.375 * (VOL/RATE)

; VOL = Vol of 1 Cylinder in liters, (0.7125l)

; RATE = Injector flow in grams/sec

; 5.7L = 2.331 grams/sec (#/HR)

; (VOL/RATE) = 0.3056 l/gm/sec

; LD2B4 BPW = 112

;------------------------------------------

;---------------------------------------------

; EGR OFF-TO-ON FILTER

;---------------------------------------------

LD2B5 FCB 15 ; 5.86%, EGR off filter coef

LD2B6 FCB 32 ; 12.5%, EGR on filter coef

________________________________________________

|

|

|

|

|

09-10-2010, 02:49 PM

09-10-2010, 02:49 PM

|

#167 (permalink)

|

|

oldschool

Join Date: May 2010

Location: Illinois

Posts: 184

Thanks: 21

Thanked 35 Times in 25 Posts

|

continued again:

Quote:

;================================================= ====

; 5.7l LOAD w/back-pressure EGR (ARJU)

; This table provided a corrected value of effective

; (cyl vol/Inj flow) rate (ratio) when EGR is active.

; 1. Inj Flow is per bank, in grams/sec

; 2. Cyl vol is liters/cylinder

; 3. Ratio = cyl vol/Inj flow

; The resulting value is used to predict fuel flow using the

; speed density method. During EGR off/on transients the value is

; filtered between the value at LD2B4 and the table value for smoothing.

; 189.48 = 1461.5 * 7.713 g/sec TBI

; TABLE = 1461.5 * Volume/rate

;================================================= ====

;-------------------------------------

; EGR-ON BPW Compensation vs air-flow vs %EGR

; 02-03-2000 ARJU, 17 COL x 5 BLOCKS = 85 BYTES

; TABLE = 189.48 * Cylinder Volume

;-------------------------------------

ORG $0324 ; TABLE LIMITS

LD324 FCB 16 ; 8gm/sec MIN Air Flow Value

LD325 FCB 0 ; 0% MIN EGR Value

LD326 FCB 17 ; LINES/BLOCK

;---------------------------------------------

; 8 Air Flow Cyl Vol EGR %

;---------------------------------------------

LD327 FCB 135 ; 0.7125 0.0

LD328 FCB 135 ; 0.7125 6.3

LD329 FCB 132 ; 0.6966 12.5

LD32A FCB 128 ; 0.6755 18.8

LD32B FCB 123 ; 0.6491 25.0

LD32C FCB 123 ; 0.6491 31.3

LD32D FCB 123 ; 0.6491 37.5

LD32E FCB 123 ; 0.6491 43.8

LD32F FCB 123 ; 0.6491 50.0

LD330 FCB 123 ; 0.6491 56.3

LD331 FCB 123 ; 0.6491 62.5

LD332 FCB 123 ; 0.6491 68.8

LD333 FCB 123 ; 0.6491 75.0

LD334 FCB 123 ; 0.6491 81.3

LD335 FCB 123 ; 0.6491 87.5

LD336 FCB 123 ; 0.6491 93.8

LD337 FCB 123 ; 0.6491 100.0

;---------------------------------------------

; 16 Air Flow Cyl Vol EGR %

;---------------------------------------------

LD338 FCB 135 ; 0.7125 0.0

LD339 FCB 135 ; 0.7125 6.3

LD33A FCB 132 ; 0.6966 12.5

LD33B FCB 128 ; 0.6755 18.8

LD33C FCB 123 ; 0.6491 25.0

LD33D FCB 123 ; 0.6491 31.3

LD33E FCB 123 ; 0.6491 37.5

LD33F FCB 123 ; 0.6491 43.8

LD340 FCB 123 ; 0.6491 50.0

LD341 FCB 123 ; 0.6491 56.3

LD342 FCB 123 ; 0.6491 62.5

LD343 FCB 123 ; 0.6491 68.8

LD344 FCB 123 ; 0.6491 75.0

LD345 FCB 123 ; 0.6491 81.3

LD346 FCB 123 ; 0.6491 87.5

LD347 FCB 123 ; 0.6491 93.8

LD348 FCB 123 ; 0.6491 100.0

;---------------------------------------------

; 24 Air Flow Cyl Vol EGR %

;---------------------------------------------

LD349 FCB 135 ; 0.7125 0.0

LD34A FCB 135 ; 0.7125 6.3

LD34B FCB 132 ; 0.6966 12.5

LD34C FCB 128 ; 0.6755 18.8

LD34D FCB 123 ; 0.6491 25.0

LD34E FCB 123 ; 0.6491 31.3

LD34F FCB 123 ; 0.6491 37.5

LD350 FCB 123 ; 0.6491 43.8

LD351 FCB 123 ; 0.6491 50.0

LD352 FCB 123 ; 0.6491 56.3

LD353 FCB 123 ; 0.6491 62.5

LD354 FCB 123 ; 0.6491 68.8

LD355 FCB 123 ; 0.6491 75.0

LD356 FCB 123 ; 0.6491 81.3

LD357 FCB 123 ; 0.6491 87.5

LD358 FCB 123 ; 0.6491 93.8

LD359 FCB 123 ; 0.6491 100.0

;---------------------------------------------

; 32 Air Flow Cyl Vol EGR %

;---------------------------------------------

LD35A FCB 135 ; 0.7125 0.0

LD35B FCB 135 ; 0.7125 6.3

LD35C FCB 132 ; 0.6966 12.5

LD35D FCB 128 ; 0.6755 18.8

LD35E FCB 123 ; 0.6491 25.0

LD35F FCB 123 ; 0.6491 31.3

LD360 FCB 123 ; 0.6491 37.5

LD361 FCB 123 ; 0.6491 43.8

LD362 FCB 123 ; 0.6491 50.0

LD363 FCB 123 ; 0.6491 56.3

LD364 FCB 123 ; 0.6491 62.5

LD365 FCB 123 ; 0.6491 68.8

LD366 FCB 123 ; 0.6491 75.0

LD367 FCB 123 ; 0.6491 81.3

LD368 FCB 123 ; 0.6491 87.5

LD369 FCB 123 ; 0.6491 93.8

LD36A FCB 123 ; 0.6491 100.0

;---------------------------------------------

; 40 Air Flow Cyl Vol EGR %

;---------------------------------------------

LD36B FCB 135 ; 0.7125 0.0

LD36C FCB 135 ; 0.7125 6.3

LD36D FCB 132 ; 0.6966 12.5

LD36E FCB 128 ; 0.6755 18.8

LD36F FCB 123 ; 0.6491 25.0

LD370 FCB 123 ; 0.6491 31.3

LD371 FCB 123 ; 0.6491 37.5

LD372 FCB 123 ; 0.6491 43.8

LD373 FCB 123 ; 0.6491 50.0

LD374 FCB 123 ; 0.6491 56.3

LD375 FCB 123 ; 0.6491 62.5

LD376 FCB 123 ; 0.6491 68.8

LD377 FCB 123 ; 0.6491 75.0

LD378 FCB 123 ; 0.6491 81.3

LD379 FCB 123 ; 0.6491 87.5

LD37A FCB 123 ; 0.6491 93.8

LD37B FCB 123 ; 0.6491 100.0

;---------------------------------------------

_____________________________________________

|

and the algorithm:

Quote:

;=================================================

; REAL TIME SERVICE ROUTINE 3

;=================================================

EB59: PULX ; PULL X REGISTER FROM STACK

EB5A: LDX #$D1B3 ; POINT TO EGR PARAMETERS

EB5D: LDAB L0006 ; GET EGR STATUS IN REGISTER B

EB5F: LDAA 0,X ; GET 48c COOLANT FOR EGR ENABLE (1K PU) TABLE 3

EB61: CMPA L00E3 ; COMPARE A TO INVERSE COOLANT, 1k pu (COOLANT VALUE INVERSED)

EB63: BLS LEBA5 ; IF COOLANT FOR ENABLE LT COOLANT VALUE, BRANCH TO $EBA5 (SKIP OTHER CHECKS)

EB65: LDAA 6,X ; GET 38 Kpa MAP, HI VACUUM FOR EGR ENABLE

EB67: BITB #$10 ; TEST b4 IN $L0006 (EGR ALREADY ON/OFF ?)

EB69: BEQ LEB6D ; IF NOT b4, BRANCH TO $EB6D (SKIP LOW MAP TEST)

EB6B: LDAA 5,X ; 35 Kpa MAP, LO VACUUM FOR EGR ENABLE

EB6D: LEB6D CMPA L0031 ; COMPARE A TO VACUUM

EB6F: BLS LEB75 ; IF VACUUM VALUE GT ENABLE THRESH, BRANCH TO $EB75

EB71: ANDB #$EF ; CLEAR b4 IN $L0006 EGR STATUS (TURN EGR OFF)

EB73: BRA LEBA3 ; BRANCH ALWAYS TO $EBA3 (TURN EGR OFF)

;---------------------------------

EB75: LEB75 ORAB #$10 ; SET b4 IN $L0006 (EGR STATUS ON)

EB77: LDAA L0009 ; GET FLAG WORD

EB79: BITA #$24 ; TEST b5,b2

EB7B: BNE LEB8F ; IF b5,b2 BRANCH TO $EB8F (SKIP TPS CHECK)

EB7D: LDAA 4,X ; GET 3%, HI TPS FOR EGR ENABLE

EB7F: BITB #$20 ; TEST b5 IN $L0006 (EGR STATUS ON/OFF ?)

EB81: BEQ LEB85 ; IF NOT b5 BRANCH TO $EB85 (SKIP LOW TPS THRESH)

EB83: LDAA 3,X ; GET 2%, LOW TPS THRESH FOR EGR ENABLE

EB85: LEB85 CMPA L0049 ; COMPARE A TO CURRENT TPS VALUE

EB87: BCS LEB8D ; IF TPS GT THRESH, BRANCH TO $EB8D

EB89: ANDB #$DF ; CLEAR b5 IN $L0006 (TURN EGR OFF)

EB8B: BRA LEBA3 ; BRANCH ALWAYS TO $EBA3

;---------------------------------

EB8D: LEB8D ORAB #$20 ; SET b5 IN REGISTER B

EB8F: LEB8F LDAA L00DE ; GET STATUS WORD

EB91: BITA #$40 ; TEST b6

EB93: BNE LEBAB ; IF b6, BRANCH TO $EBAB

EB95: LDAA 2,X ; GET 0 MPH HI VSS THRESHOLD FOR EGR ENABLE

EB97: BITB #$40 ; TEST b6 IN $L0006

EB99: BEQ LEB9D ; IF NOT b6, BRANCH TO $EB9D (SKIP LO VSS THRESH)

EB9B: LDAA 1,X ; GET 0 MPH LO VSS THRESHOLD FOR EGR ENABLE

EB9D: LEB9D CMPA L0034 ; COMPARE A TO FILTERED VSS MPH/1

EB9F: BLS LEBA9 ; IF VSS GT THRESHOLD BRANCH TO $EBA9

EBA1: ANDB #$BF ; CLEAR b6 IN $L0006 (TURN EGR OFF)

EBA3: LEBA3 STAB L0006 ; UPDATE EGR STATUS

EBA5: LEBA5 CLRA ; CLEAR A REGISTER

EBA6: JMP LEC00 ; JUMP TO $EC00 (UPDATE PERCENT EGR)

;---------------------------------

;=================================================

; PERCENT EGR Vs. VACUUM LOAD vs RPM TBL = 2.56 * %EGR

; 01-31-1996 Dissassemby of ASDZ Blocks = 7

; RPM 1000, 1200, 1400, 1600, 1800, 2200, 3000

;=================================================

EBA9: LEBA9 ORAB #$40 ; SET b6

EBAB: LEBAB STAB L0006 ; UPDATE EGR STATUS

EBAD: LDX #$D1C0 ; POINT TO PERCENT EGR Vs. VACUUM LOAD vs RPM

EBB0: JSR LFA4D ; GOSUB $FA4D (Return with MAP or VACUUM in A REGISTER)

;---------------------------------

EBB3: LSRA ; RESULT/2

EBB4: TAB ; TRANSFER A REGISTER TO B REGISTER

EBB5: LDAA L001F ; GET RPM/12.5 (FILTERED)

EBB7: CMPA #144 ; COMPARE A REGISTER TO 1800 RPM

EBB9: BLS LEBCB ; IF RPM LT 1800 BRANCH TO $EBCB (3-D LOOK-UP)

EBBB: LSRA ; RPM/2

EBBC: ADDA #72 ; ADD 72 (900 RPM) TO A REGISTER

EBBE: CMPA #160 ; COMPARE TO 2000 RPM/12.5

EBC0: BLS LEBCB ; IF LT 2000 RPM BRANCH TO $EBCB (3-D LOOK-UP)

EBC2: LSRA ; RPM/2

EBC3: ADCA #80 ; ADD 80 (1000 RPM) WITH CARRY TO A REGISTER

EBC5: CMPA #80 ; COMPARE A REGISTER TO 1000 RPM

EBC7: BLS LEBCB ; IF RPM LT 1000 BRANCH TO (3-D LOOK-UP)

EBC9: LDAA #176 ; GET 4400 RPM

EBCB: LEBCB JSR LFB67 ; GOSUB 3-D LOOK-UP

;---------------------------------

EBCE: STAA L0058 ; UPDATE PERCENT EGR, (temp variable)

;=================================================

; EGR GAIN vs COOLANT VALUE = N * 128

;=================================================

EBD0: LDX #$D1F5 ; POINT TO TABLE EGR GAIN vs COOLANT

EBD3: LDAA L0021 ; GET COOLANT

EBD5: LDAB #40 ; COOLANT ARG, LOWER LIMIT

EBD7: JSR LFB37 ; GOSUB 2d LOOK-UP, WITH LOWER ARG LIMIT

EBDA: BSR LEC22 ; GOSUB (UPDATE EGR%)

;---------------------------------

EBDC: LDAA LD1BF ; GET 50% TPS HI TPS THRESHOLD EGR AFTER 50% GAIN = 0

EBDF: CMPA L0049 ; COMPARE TO CURRENT TPS VALUE

EBE1: BCS LEBA5 ; IF TPS GT THRESHOLD BRANCH TO $EBA5

;=================================================

; EGR GAIN FACTOR vs BAROMETER & MAP 3d TABLE = GAIN * 128

;=================================================

EBE3: JSR LFD18 ; GOSUB $FD18 GET PROCESSED BAROMETER VALUE IN A

EBE6: TAB ; PUT PROCESSED BARO IN BOTH A & B Registers

EBE7: LDX #$D1FE ; POINT TO EGR GAIN GAIN FACTOR vs BARO & MAP 3d

EBEA: LDAA L0026 ; GET S/D MAP

EBEC: LSRA ; REGISTER A/2

EBED: JSR LFB67 ; GOSUB 3d LOOK-UP

EBF0: BSR LEC22 ; GOSUB $EC22 (UPDATE EGR%)

;=================================================

; FILTER EGR

;=================================================

EBF2: LDAA L0080 ; GET PERCENT EGR INTO A REGISTER

EBF4: CLRB ; CLEAR B REGISTER

EBF5: PSHB ; PUSH B REGISTER ONTO STACK

EBF6: PSHA ; PUSH A REGISTER ONTO STACK

EBF7: PULX ; PULL X REGISTER FROM STACK (2 BYTES)

EBF8: LDAA L0058 ; GET PERCENT EGR (temp) INTO A

EBFA: LDAB LD1BC ; GET 0.898 EGR D.C. FILTER COEF INTO B

EBFD: JSR LFB12 ; GOSUB LAG FILTER

;---------------------------------

EC00: LEC00 STAA L0080 ; UPDATE FILTERED PERCENT EGR

;=================================================

; CHECK IF HEADS-UP ON-LINE EGR MODE

;=================================================

EC02: LDAB L0000 ; GET STATUS MODE WORD

EC04: BITB #$02 ; TEST b1

EC06: BEQ LEC0B ; BRANCH IF NOT b1

EC08: JSR L5806 ; GOTO HEADS UP <-------<<

;---------------------------------

EC0B: LEC0B LDAB #160 ;

EC0D: MUL ;

EC0E: ADCA #$00 ;

;=================================================

; VACUUM LIMITER

;=================================================

EC10: LDAB L0031 ; GET VACUUM IN B REGISTER

EC12: CMPB #192 ; COMPARE B REGISTER TO VACUUM LIMIT aprox 20 Kpa

EC14: BCC LEC2D ; IF VALUE LESS THAN BRANCH TO $EC2D

EC16: CMPB #64 ; COMPARE TO VACUUM LIMIT aprox 70 Kpa

EC18: BHI LEC1C ; IF RESULT HIGHER THAN BRANCH TO $EC1C (SKIP 70 KPA LIMIT)

EC1A: LDAB #64 ; GET VACUUM LIMIT aprox 70 Kpa INTO B REGISTER

EC1C: LEC1C NEGB ; two's complement into B register

EC1D: LSRB ; Divide B register by two

EC1E: ADDB #96 ; ADD 60 kpa TO B REGISTER

EC20: BRA LEC2F ; BRANCH ALWAYS TO $EC2F

;=================================================

; UPDATE EGR%

;=================================================

EC22: LEC22 LDAB L0058 ; GET PERCENT EGR (Temp)

EC24: MUL ; MULTIPLY A x B REGISTERS = D REGISTER

EC25: ASLD ; MULTIPLY D REGISTER BY TWO

EC26: BCC LEC2A ; IF NO OVERFLOW BRANCH TO $EC2A (SKIP MAX VALUE)

EC28: LDAA #255 ; FORCE MAX VALUE

EC2A: LEC2A STAA L0058 ; UPDATE PERCENT EGR (Temp)

EC2C: RTS ;---------------------------------

EC2D: LEC2D NEGB ; two's complement into B register

EC2E: ASLB ; MULTIPLY B REGISTER BY TWO

;=================================================

;* EGR CORRECTION vs VACUUM vs EGR Duty Cycle

;* ASDZ BP EGR TABLE = Factor * 256

;=================================================

EC2F: LEC2F LDX #$D21D ; POINT TO TABLE EGR CORRECTION vs VACUUM vs EGR D.C.

EC32: JSR LFB67 ; GO DO 3d LOOK-UP

;---------------------------------

EC35: STAA L007F ; UPDATE EGR CORRECTION (air flow for EGR)

EC37: LDAB L0006 ; GET STATUS WORD

EC39: ANDB #$7F ; CLEAR b7 EGR OFF

EC3B: LDAA L0080 ; GET PERCENT EGR

EC3D: CMPA LD1BD ; COMPARE TO 19.9% D.C. THRESHOLD FOR EGR ON

EC40: BLS LEC51 ; BRANCH IF LOWER OR SAME

EC42: LDAA L0031 ; GET VACUUM

EC44: CMPA LD1BE ; COMPARE TO 1 Kpa VACUUM THRESH FOR EGR ON, (100 Kpa)

EC47: BHI LEC51 ; IF VACUUM GT THRESHOLD BRANCH TO $EC51 (UPDATE STATUS)

EC49: LDAA L000A ; GET DIAGNOSTICS STATUS WORD

EC4B: BITA #$01 ; TEST b0 (DIAGNOSTICS STATUS) (DOING SOME TEST ?)

EC4D: BNE LEC51 ; IF RESULT NOT ZERO BRANCH TO $EC51 (SKIP TURNING EGR ON)

EC4F: ORAB #$80 ; SET b7, EGR ON

EC51: LEC51 STAB L0006 ; UPDATE STATUS WORD

EC53: JMP LE548 ; GO TO $E548

;---------------------------------

_________________________________________________

|

|

|

|

|

09-10-2010, 03:13 PM

09-10-2010, 03:13 PM

|

#168 (permalink)

|

|

oldschool

Join Date: May 2010

Location: Illinois

Posts: 184

Thanks: 21

Thanked 35 Times in 25 Posts

|

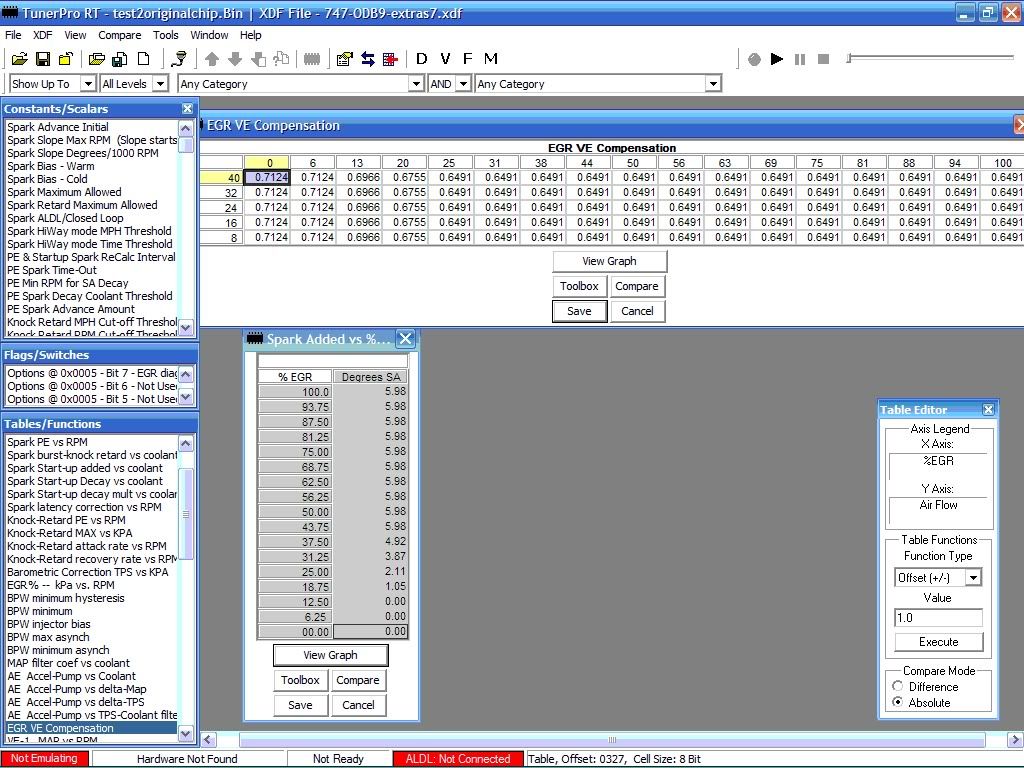

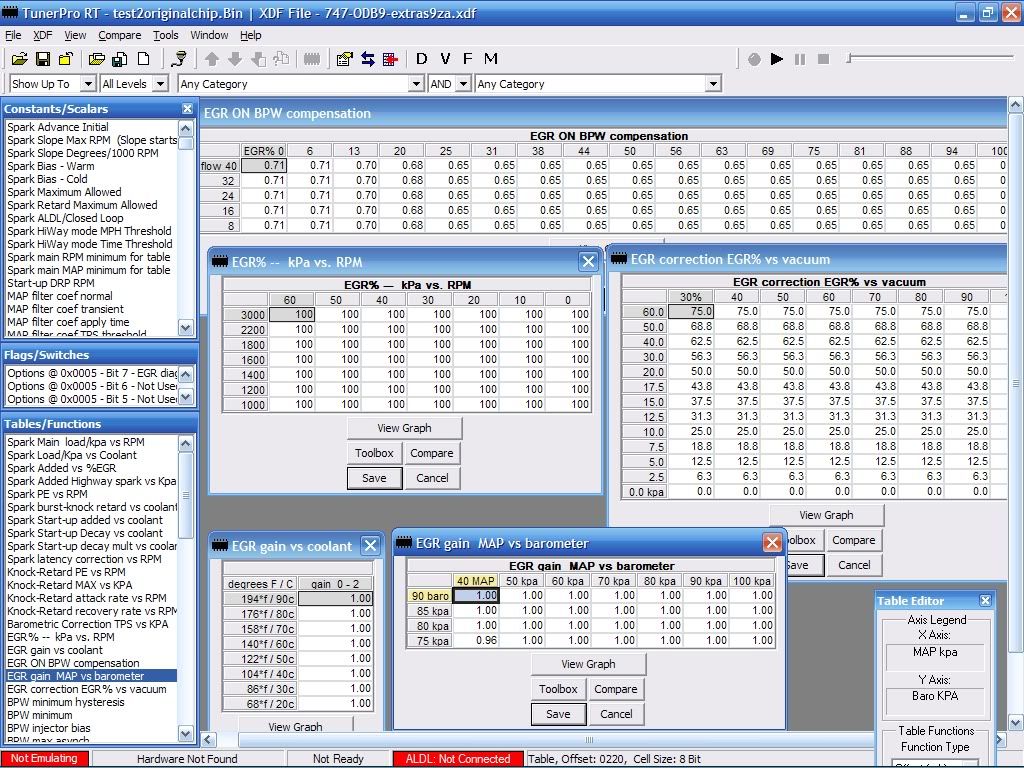

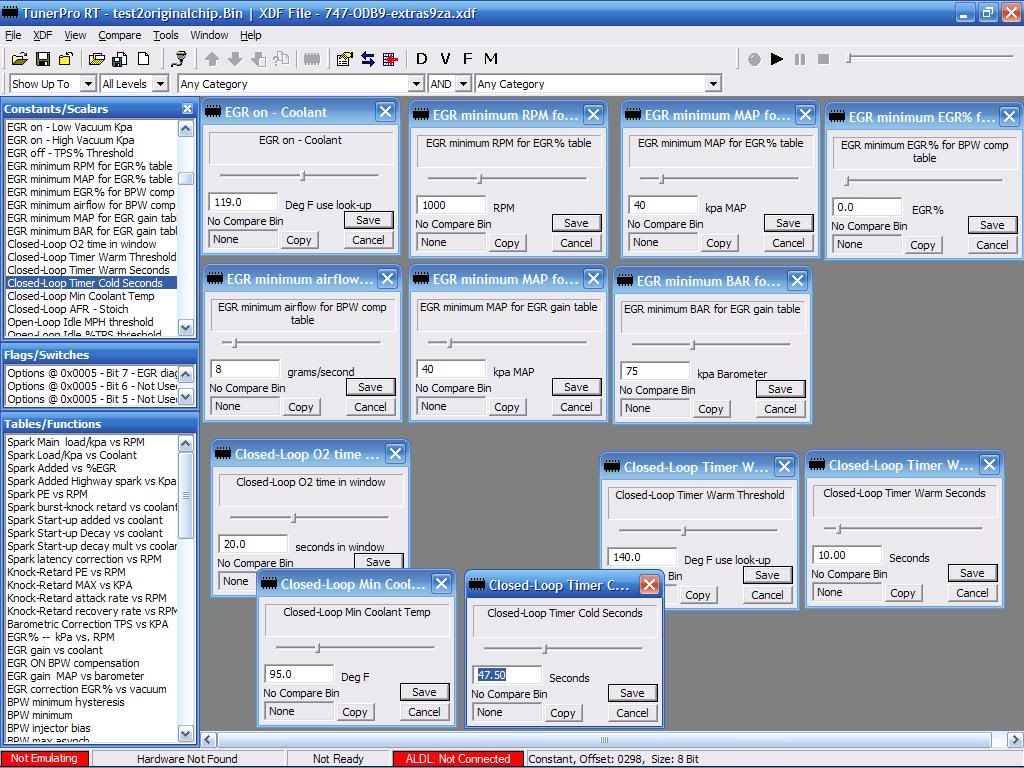

Screen-shots of the calibration tables/constants.

The first table is the VE compensation, where you see that the effective VE is reduced for use in the fueling calculations based on a 35% reduction due to EGR contamination.

Some of these calibration tables are misleading in that some aren't used in my application, and the fact that only part of this VE compensation table is actually used in my application due to the type of hardware operation the factory provided. My particular EGR system did not incorporate a duty-cycle (DC) type of EGR controller. Some other vehicle models did.

http://i702.photobucket.com/albums/w...EGRscreen1.jpg

In the next shot you can see how one of the fuel injector constants is adjusted for EGR-on operation in order to compensate for some of the fuel adders during transients. Most of the gains aren't used in my application since there was no way to apply them directly to the EGR flow.

http://i702.photobucket.com/albums/w...Rscreen2-1.jpg

Below you can see some of the qualifying thresholds for EGR operation. I added some of the closed-loop qualifiers as well. The EGR only functions in closed-loop.

http://i702.photobucket.com/albums/w...Rscreen3-1.jpg

Only about 80% of the EGR information is shown here. When active, EGR has a hand in a great many ECM functions via checks and compensations.

Note, there is no PE threshold compensation for EGR-on in this calibration, nor do I commonly see one. That means that the vehicle will go into PE Power-Enrichment more often when running the EGR. The lower power output produced combined with more TPS% and more MAP - manifold pressure requires that this be the case. AE - Acceleration-Enrichment is also activated more, and more often with the use of EGR.

You should try to compensate for these conditions when trying to gain MPG while using the EGR.

__________________

#####################################

|

|

|

|

09-10-2010, 03:36 PM

09-10-2010, 03:36 PM

|

#169 (permalink)

|

|

oldschool

Join Date: May 2010

Location: Illinois

Posts: 184

Thanks: 21

Thanked 35 Times in 25 Posts

|

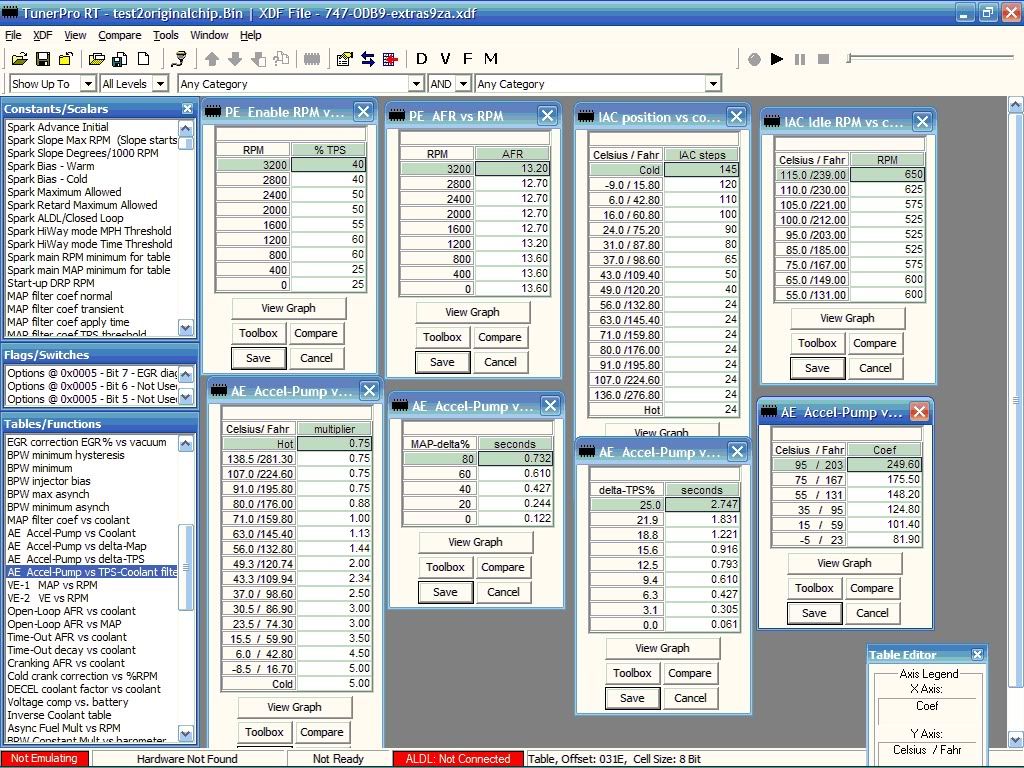

PE and AE qualifiers

This/these (all code and images) are for a 350cid/5.7L V8 engine.

Other engines use a combination of TPS% and MAP/MAF thresholds to initiate both PE and AE, and some can activate sooner and more often than this example. It's always best to check what you've got and not assume what's happening. Smaller engines or engines in an under-powered combination tend to be calibrated for earlier enrichment activation. Some people think that it only happens at WOT, but that's not true. This is a case where good data-logging and/or a WBO2 display can be very revealing if the data capture and display has a quick update rate.

EGR acts like a buffer in the chamber and so increases the requirement for enrichment fuel under conditions that necessitate PE or AE. Luckily the factory calibrations (usually) already overshoot the added fuel requirement by 15% or more. MPFI systems can usually get away with amazingly small amounts of AE, and a reduced amount of PE over a wet-flow system like TBI.

The amount of PE and AE can be further reduced by reducing the spark advance - basically taking away the PE spark adder. Power and response are reduced, but this is common-course for many eco-mods.

Here's a shot with some of the PE and AE qualifiers.

http://i702.photobucket.com/albums/w...EAEscreen1.jpg

__________________

#####################################

|

|

|

|

09-10-2010, 07:53 PM

09-10-2010, 07:53 PM

|

#170 (permalink)

|

|

Master EcoModder

Join Date: Jul 2009

Location: New York

Posts: 513

Thanks: 2

Thanked 101 Times in 74 Posts

|

things change

...."This wouldn't be so bad except for the fact that the EGR algorithm is factory programmed to deliver the EGR charge during times of needed power production."....

......"EGR acts like a buffer in the chamber and so increases the requirement for enrichment fuel under conditions that necessitate PE or AE.".......

original EGR design focused on NOX reduction

but that is no longer the case .

in my experience , the system any system

will switch the EGR flow off

right away

before it will add any enrichment .

current EGR systems are NOTHING like what would be found in your 1986 camaro or 1991 truck

what car what system ?

and

why do you think more mass is entering the combustion chamber when the EGR is on as opposed to when EGR is off ?

MOST current systems use MAF sensors NOT speed density systems

Load is DECREASED with EGR operation

repeat your testing with your focus to see .

|

|

|

|

|