07-29-2015, 08:40 AM

07-29-2015, 08:40 AM

|

#31 (permalink)

|

|

EcoModding Apprentice

Join Date: Jul 2015

Location: Barcelona

Posts: 104

Thanks: 75

Thanked 63 Times in 37 Posts

|

Quote:

Originally Posted by elhigh

+1 on lengthening the car and laying the driver down. As Freebeard pointed out that will improve the fineness ratio and allow you, with the lower helmet position, to also lower the roll bar and get it out of the wind. Incorporating a fairing into the downwind portion of the rollbar would be good, esp. if you can also have a windshield that will aerodynamically couple to the upwind side of the roll bar. Things could get very sleek at that point.

Your suspension is an aerodynamic mess. If you can fair the fore-and-aft elements together, you have only half as many wakes to contend with.

+1 on adding smoothie discs to the wheels.

Virtually any body at all is going to perform better than your bare tube chassis. If you're breaking 60kmh already, get ready for a big surprise when you add some body panels.

It sounded to me like you were describing how you had added weight to the wheels to make them coast longer. If you're running with weight in the wheels, get it out. Move the weight into the body itself, as low and as centrally located as possible. Lighter wheels accelerate better and give a much smoother ride, and keeping the weight low will allow the car to take turns better.

|

Hi elhigh,

i'm already working on the driver position, but i have to clear the break pedal and the steering column.

A windshield will be awesome!

Ok, so i have to streamline the suspension arms, and move the coiler to inside the cabin.

the body panels would make such a difference ? i would need to search some road to test and measure the improvements.

i don't put weight on the wheels, I'm trying to lighten them as much as i can to reduce inertia.

Some news on the project:

Fiberglass arrived today! now time to make the molds.

|

|

|

|

|

The Following 2 Users Say Thank You to orengomotors For This Useful Post:

|

|

Today Today

|

|

|

|

Other popular topics in this forum...

Other popular topics in this forum...

|

|

|

|

07-29-2015, 05:06 PM

07-29-2015, 05:06 PM

|

#32 (permalink)

|

|

Master EcoModder

Join Date: Jan 2008

Location: Sanger,Texas,U.S.A.

Posts: 16,489

Thanks: 24,515

Thanked 7,436 Times in 4,817 Posts

|

about this

Quote:

Originally Posted by orengomotors

hi Aerohead,

I think I can not adapt the soapbox to that solar car design, the shape is a lot different.

what do you think about this:

thank you! |

*I'd recommend a flat bottom,except for a 2.5-degree diffuser if you can do that.There is no reason to let air under the nose of the car.

*Sculpt a close-fitting fairing in front of you,to guide the airflow onto you in your safety gear.

*Your 'turtledeck' rear fairing needs to blend into your helmet,shoulders,and anything else exposed to the air.

*Fill the void between the fairings and yourself with foam padding )kinda like is done with a kayak) to prevent errant air from entering the cockpit.

*The roll bar tubing should be streamlined.

*All exposed suspension and steering links should be streamlined.

*The wheel fairings should have the 'slowest' contours that you can stand.Very slender,very long! And they could be at least as low as the bottom of the wheels outer rim.

__________________

Photobucket album: http://s1271.photobucket.com/albums/jj622/aerohead2/

|

|

|

|

07-29-2015, 05:09 PM

07-29-2015, 05:09 PM

|

#33 (permalink)

|

|

Master EcoModder

Join Date: Jan 2008

Location: Sanger,Texas,U.S.A.

Posts: 16,489

Thanks: 24,515

Thanked 7,436 Times in 4,817 Posts

|

frontal area

Quote:

Originally Posted by orengomotors

my driving position is a bit upright:

I can change the seat to be more horitzontal, and so minimize the frontal area and drag. what you think? |

Yes,anything to minimize frontal area will pay you dividends.

__________________

Photobucket album: http://s1271.photobucket.com/albums/jj622/aerohead2/

|

|

|

|

07-29-2015, 05:19 PM

07-29-2015, 05:19 PM

|

#34 (permalink)

|

|

Master EcoModder

Join Date: Jan 2008

Location: Sanger,Texas,U.S.A.

Posts: 16,489

Thanks: 24,515

Thanked 7,436 Times in 4,817 Posts

|

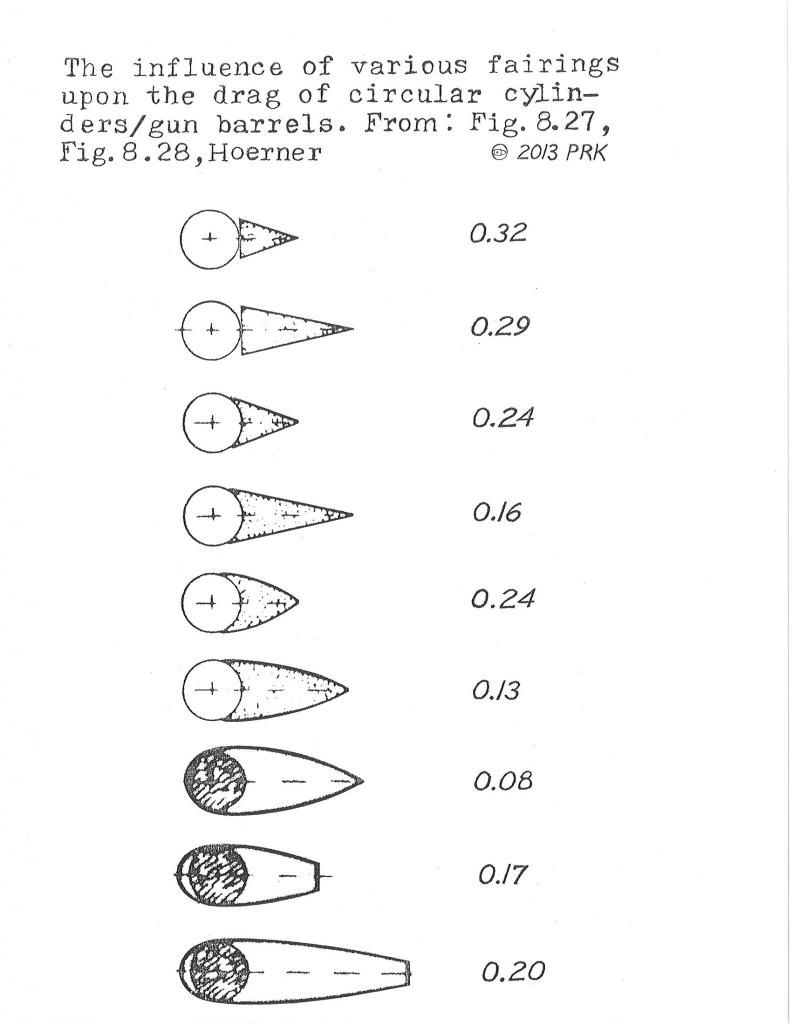

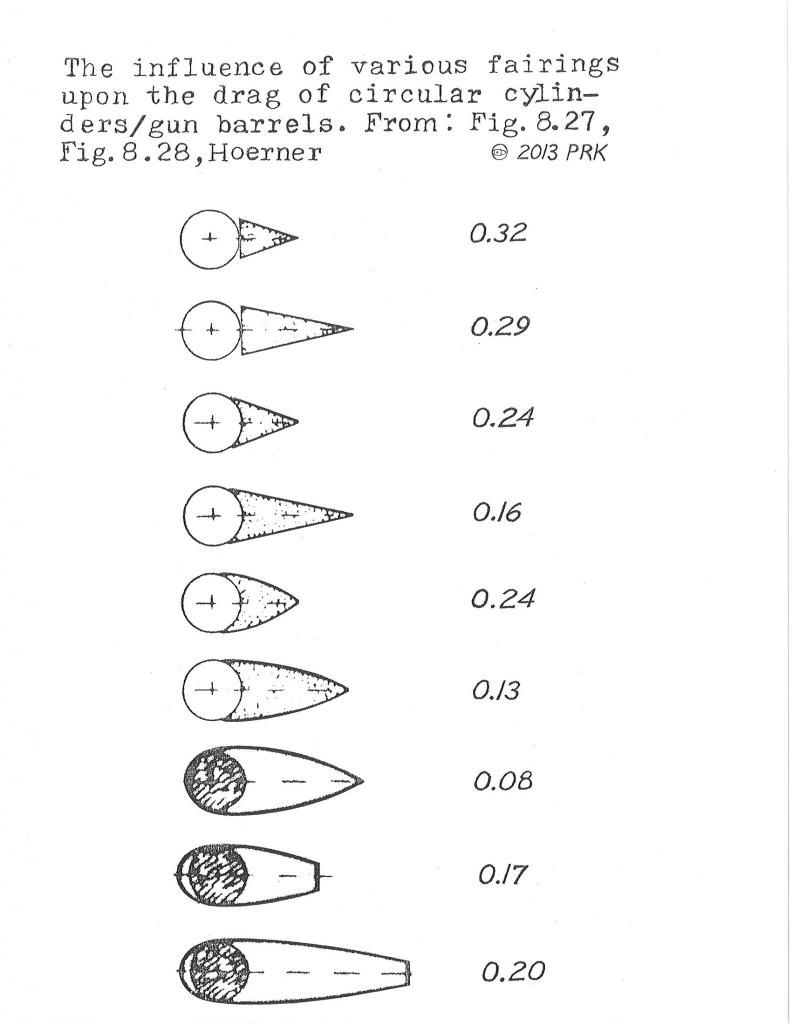

airfoil to rollbar

Quote:

Originally Posted by orengomotors

freebeard,

what do you mean by "zip-tie an airfoil to the back of the roll bar"?

the smooth wheel caps, it's a fast easy mod that i can do.

My tires have very good grip, so i reduce the contact patch to reduce rolling resistance, i run 5kg of pressure in the tires and they have a very good grip and very low friction with the road.

|

The round tubing is very high drag.Attaching a fairing to it can reduce it's drag significantly,even if it's foam rubber taped on with electrical or duct tape.

The contour,3rd from the bottom is the best.

__________________

Photobucket album: http://s1271.photobucket.com/albums/jj622/aerohead2/

|

|

|

|

|

The Following User Says Thank You to aerohead For This Useful Post:

|

|

07-30-2015, 09:32 AM

07-30-2015, 09:32 AM

|

#35 (permalink)

|

|

EcoModding Apprentice

Join Date: Jul 2015

Location: Barcelona

Posts: 104

Thanks: 75

Thanked 63 Times in 37 Posts

|

Quote:

Originally Posted by aerohead

The round tubing is very high drag.Attaching a fairing to it can reduce it's drag significantly,even if it's foam rubber taped on with electrical or duct tape.

The contour,3rd from the bottom is the best.

|

Hi Aerohead!

i had followed your advice of streamlining the rollbar.

fisrt i scaled the 3rd contour from the bottom and cutted it into wood:

next i cutted it from eps and glued it with tape:

final result:

now, somehow i have to make a mold from this.

|

|

|

|

|

The Following User Says Thank You to orengomotors For This Useful Post:

|

|

07-30-2015, 11:22 AM

07-30-2015, 11:22 AM

|

#36 (permalink)

|

|

Master Novice

Join Date: Jan 2008

Location: SE USA - East Tennessee

Posts: 2,314

Thanks: 427

Thanked 616 Times in 450 Posts

|

Hi,

Yes, I'm very sure that virtually any kind of bodywork on your gravracer will improve its speed. As it stands right now you have a whole bunch of messy wakes forming behind your chassis tubing; a body will produce just one wake, and anything you do to clean up the aerodynamic profile of that body will pay off in a big way in improved speed.

Adding fairing contours to the downwind side of your roll bar is a good first step and considering how much it sticks out in the wind, even that relatively small step may deliver noticeable improvements straightaway. If you have a hill that you usually test on and can count on very consistent results from one run to the next, take the racer there with the fairing in place and see how it's improved.

__________________

Lead or follow. Either is fine.

|

|

|

|

|

The Following User Says Thank You to elhigh For This Useful Post:

|

|

07-30-2015, 04:41 PM

07-30-2015, 04:41 PM

|

#37 (permalink)

|

|

Not Doug

Join Date: Jun 2012

Location: Show Low, AZ

Posts: 12,301

Thanks: 7,308

Thanked 2,246 Times in 1,733 Posts

|

There is a guy on YouTube that has many videos showing how to make car parts from fiberglass and he branched into carbon fiber and Kevlar. He says that before you make a mold, to use spackle, used to fill holes in drywall, to smooth it as much as possible. You are supposed to use Bondo, or body filler, but since you are just making a mold, you might as well save money.

|

|

|

|

|

The Following User Says Thank You to Xist For This Useful Post:

|

|

07-30-2015, 10:12 PM

07-30-2015, 10:12 PM

|

#38 (permalink)

|

|

Master EcoModder

Join Date: Aug 2012

Location: northwest of normal

Posts: 29,315

Thanks: 8,339

Thanked 9,098 Times in 7,514 Posts

|

Or you could skip the mold and just wrap the fiberglass cloth over the packing tape, pull it taut along the trailing edge and fiberglass it. If you were making multiple copies a mold might be worth the effort.

OTOH, if you have more EPS you might recut those. The 0.08 cross-section has a maximum thickness greater than the tubing diameter, and a full half-circular cutout. Your pieces have the center in contact while the tips stand proud. Or you could add wedge shaped strips to fill the gap. |

|

|

|

|

The Following User Says Thank You to freebeard For This Useful Post:

|

|

07-31-2015, 02:56 AM

07-31-2015, 02:56 AM

|

#39 (permalink)

|

|

Easter McoModder

Join Date: Mar 2010

Location: West Texas, US

Posts: 363

Thanks: 212

Thanked 28 Times in 26 Posts

|

thanks for the great aero ideas! keep up the good work. can't wait to see what you come up with!

best

|

|

|

|

07-31-2015, 04:28 AM

07-31-2015, 04:28 AM

|

#40 (permalink)

|

|

EcoModding Apprentice

Join Date: Jul 2015

Location: Barcelona

Posts: 104

Thanks: 75

Thanked 63 Times in 37 Posts

|

Quote:

Originally Posted by freebeard

Or you could skip the mold and just wrap the fiberglass cloth over the packing tape, pull it taut along the trailing edge and fiberglass it. If you were making multiple copies a mold might be worth the effort.

OTOH, if you have more EPS you might recut those. The 0.08 cross-section has a maximum thickness greater than the tubing diameter, and a full half-circular cutout. Your pieces have the center in contact while the tips stand proud. Or you could add wedge shaped strips to fill the gap. |

Hi Freebeard,

i will redo those.

|

|

|

|

|